Create Functional Prototypes for Your Product with These Tips

By:Admin

In the fast-paced world of technology and innovation, the creation of functional prototypes plays a crucial role in the development and design of new products. {} is at the forefront of this industry, offering cutting-edge solutions for companies in need of high-quality prototypes.

With a strong focus on the latest technological advancements, {} has established itself as a leader in the field of functional prototypes. The company's dedication to precision and quality has set it apart from its competitors, earning the trust and confidence of clients across various industries.

{}'s state-of-the-art facilities are equipped with advanced machinery and software, allowing for the production of complex and highly detailed prototypes. The company's team of skilled engineers and designers work closely with clients to understand their specific needs and requirements, ensuring that each prototype is tailored to perfection.

One of the key advantages of {}'s services is the speed at which prototypes can be produced. The company's streamlined process and efficient workflow enable clients to receive their prototypes in a timely manner, allowing them to move forward with their product development and testing.

Furthermore, {}'s dedication to quality control ensures that each prototype meets the highest standards of excellence. Rigorous testing and inspection procedures are carried out to guarantee that the final product is free of any defects or imperfections.

The impact of {}'s functional prototypes can be seen in a wide range of industries, from automotive and aerospace to consumer electronics and medical devices. By providing clients with accurate and reliable prototypes, {} is helping to drive innovation and progress in various sectors.

{}'s commitment to innovation and excellence has earned it a stellar reputation in the industry, with a growing list of satisfied clients who have benefited from its services. The company's ability to deliver on its promises and exceed expectations has solidified its position as a trusted partner for companies in need of functional prototypes.

As technology continues to advance at a rapid pace, the demand for functional prototypes is only expected to grow. {} is well-positioned to meet this demand, thanks to its cutting-edge capabilities and unwavering commitment to excellence.

In the coming years, {} aims to expand its reach and further cement its status as a leader in the field of functional prototypes. By staying ahead of the curve and embracing new technologies and techniques, the company is poised to continue making significant contributions to the world of innovation and product development.

In conclusion, {} is revolutionizing the way companies approach the creation of functional prototypes. With its advanced capabilities, streamlined process, and unwavering commitment to quality, the company is setting new standards in the industry and helping to shape the future of technology and innovation. Clients can trust in {} to deliver top-of-the-line prototypes that meet their specific needs and propel their product development efforts forward.

Company News & Blog

Top Tips for Machining Prototyping in Manufacturing

Machining Prototyping is a leading provider of precision machining and prototyping services, offering a wide range of solutions to meet the needs of various industries. With a commitment to quality, innovation, and customer satisfaction, Machining Prototyping has become a trusted partner for companies looking to bring their designs to life.The company specializes in CNC machining, 3D printing, and rapid prototyping, utilizing advanced technologies and state-of-the-art equipment to deliver high-quality parts and prototypes. Whether it's a small batch of custom parts or a complex prototype, Machining Prototyping has the expertise and capabilities to turn ideas into reality.One of the key factors that sets Machining Prototyping apart from its competitors is its dedication to continuous improvement and innovation. The company invests in research and development, staying at the forefront of industry trends and technologies to ensure that its customers receive the best possible solutions for their projects.Machining Prototyping's team of skilled engineers and technicians work closely with clients to understand their requirements and provide tailored solutions that meet their exact specifications. From the initial design phase to the final product, the company's collaborative approach ensures that all projects are completed with precision and efficiency.In addition to its machining and prototyping services, Machining Prototyping also offers design assistance and engineering support to help clients optimize their designs for manufacturability. By leveraging its extensive knowledge and expertise, the company helps customers streamline the production process and achieve cost-effective solutions without compromising on quality.With a strong focus on customer satisfaction, Machining Prototyping places great importance on communication and transparency throughout the entire project lifecycle. The company's responsive and dedicated customer support team ensures that clients are kept informed at every stage, providing peace of mind and confidence in the final outcome.Moreover, Machining Prototyping is committed to environmental sustainability and responsible manufacturing practices. The company adheres to strict quality control measures and ethical standards, utilizing eco-friendly materials and processes whenever possible.In recent news, Machining Prototyping has expanded its capabilities with the acquisition of new cutting-edge equipment, further enhancing its ability to deliver complex and high-precision parts and prototypes. This strategic investment demonstrates the company's ongoing commitment to staying ahead of the curve and meeting the evolving needs of its customers."We are excited to announce the addition of [new equipment] to our facility, which will enable us to take on even more challenging projects and deliver unmatched quality to our clients," said [spokesperson], [title] at Machining Prototyping. "This expansion is a testament to our dedication to innovation and excellence, and we look forward to continuing to provide top-tier solutions to our valued partners."As Machining Prototyping continues to grow and evolve, the company remains steadfast in its mission to be a trusted partner for businesses seeking reliable, high-quality machining and prototyping services. With a focus on innovation, efficiency, and customer satisfaction, Machining Prototyping is well-positioned to meet the demands of today's fast-paced and competitive market.Whether it's a small startup or a large multinational corporation, Machining Prototyping stands ready to support businesses of all sizes and industries with their machining and prototyping needs. With a proven track record of success and a reputation for excellence, the company is poised to continue its upward trajectory and solidify its position as a leader in the industry.

Discover the Latest Innovations in Laser Cutting Technology

Laser Cutting Technology Revolutionizes Manufacturing IndustryIn today's fast-paced world, the demand for precision and high-quality manufacturing has never been greater. With the advancement of technology, the manufacturing industry has seen significant improvements in efficiency and cost-effectiveness. One such technology that has revolutionized the manufacturing industry is laser cutting.Laser cutting is a manufacturing process that uses a high-powered laser to cut or engrave materials such as metal, wood, plastic, and glass. This technology has become an integral part of many manufacturing processes due to its accuracy, speed, and versatility. By utilizing computer-aided design (CAD) software, laser cutting machines can produce intricate and complex designs with remarkable precision.One company at the forefront of laser cutting technology is {}. With over 20 years of experience in the industry, {} has established itself as a leader in providing cutting-edge laser cutting services to a wide range of industries including automotive, aerospace, electronics, and medical equipment manufacturing. The company's state-of-the-art facilities and highly skilled technicians enable them to offer customized solutions and deliver superior quality products to their clients.The use of laser cutting technology has transformed the manufacturing industry in several ways. One of the most significant advantages of laser cutting is its ability to create intricate designs with unparalleled precision. This level of accuracy allows manufacturers to produce complex components and parts with tight tolerances, leading to improved product quality and performance.Furthermore, laser cutting is a non-contact process, meaning that there is no direct tool-to-workpiece contact. This results in minimal wear and tear on the cutting equipment, reducing the need for frequent maintenance and replacement of tools. As a result, manufacturers benefit from lower operational costs and increased productivity.Another key benefit of laser cutting technology is its ability to cut a wide range of materials. Whether it's stainless steel, aluminum, titanium, or plastic, laser cutting can effectively process various materials with consistent results. This versatility makes laser cutting an ideal solution for manufacturers looking to streamline their production processes and reduce material waste.In addition to its precision and versatility, laser cutting also offers faster processing times compared to traditional cutting methods. The high-speed laser beams can swiftly cut through materials, significantly reducing the time required to manufacture parts and components. This not only improves production efficiency but also enables manufacturers to meet tight deadlines and fulfill customer orders in a timely manner.Furthermore, the automation capabilities of laser cutting technology allow for greater repeatability and consistency in manufacturing processes. This reduces the margin of error and ensures that each product meets the required specifications. As a result, manufacturers can achieve higher levels of quality control and produce standardized products with minimal variation.With the continuous advancements in laser cutting technology, the future looks promising for the manufacturing industry. As new developments emerge, manufacturers will have access to even more innovative solutions that can further enhance their production capabilities and product offerings.For companies like {}, embracing the latest laser cutting technologies will be crucial in staying competitive and meeting the evolving demands of their customers. By leveraging the benefits of laser cutting, manufacturers can achieve higher levels of precision, efficiency, and cost-effectiveness, ultimately driving the industry towards a new era of manufacturing excellence.

- The Importance of Plastic Injection Mold Tooling for Manufacturing Industry

The demand for plastic injection mold tooling has been on the rise in recent years, as more industries recognize the numerous benefits it offers. From automotive and medical to aerospace and consumer goods, plastic injection mold tooling plays a crucial role in manufacturing high-quality plastic parts and products.{Company Name}, a leading provider of plastic injection mold tooling, has been at the forefront of this industry for over 25 years. With a strong commitment to innovation and quality, {Company Name} has established itself as a trusted partner for businesses looking to enhance their plastic injection molding capabilities.The company specializes in designing and manufacturing high-precision molds for a wide range of applications. Whether it's a complex automotive component or a delicate medical device, {Company Name} has the expertise and technology to deliver custom mold tooling solutions that meet the highest performance standards.One of the key advantages of choosing {Company Name} for plastic injection mold tooling is their state-of-the-art facility equipped with the latest machinery and technology. This allows the company to handle even the most intricate mold designs with precision and efficiency, ensuring that the final products meet or exceed customer expectations.In addition to their technical capabilities, {Company Name} is known for its commitment to customer satisfaction. The company works closely with each client to understand their specific needs and requirements, and then develops a tailored mold tooling solution that aligns with their goals and budget.The team at {Company Name} brings a wealth of experience and expertise to every project, leveraging their industry knowledge to provide valuable insights and recommendations. From material selection and mold design to production processes and quality control, {Company Name} is dedicated to delivering comprehensive support at every stage of the mold tooling process.Furthermore, {Company Name} prioritizes continuous improvement and innovation, investing in research and development to stay ahead of industry trends and technological advancements. This proactive approach enables the company to offer cutting-edge mold tooling solutions that enhance the performance and efficiency of plastic injection molding operations.In recent years, {Company Name} has expanded its capabilities to offer a broader range of services, including mold maintenance, repair, and modification. This comprehensive approach allows customers to rely on {Company Name} not only for initial mold tooling, but also for ongoing support to ensure the longevity and optimal performance of their molds.The quality and reliability of {Company Name}'s plastic injection mold tooling have earned the company a stellar reputation in the industry. As a result, {Company Name} has formed long-term partnerships with leading manufacturers across various sectors, establishing itself as a trusted and preferred supplier for their mold tooling needs.Looking ahead, {Company Name} remains committed to driving innovation and delivering exceptional value to its customers. The company continues to invest in advanced technology and talent, and is dedicated to expanding its capabilities to meet the evolving needs of the plastic injection molding industry.In conclusion, the demand for plastic injection mold tooling is higher than ever, and {Company Name} is well-positioned to meet this demand with its unparalleled expertise, technology, and customer-centric approach. As the industry continues to grow and evolve, businesses can rely on {Company Name} as a strategic partner for all their plastic injection mold tooling needs.

High-Quality Plastic Mold Parts for Various Applications

Plastic Mold Parts is a renowned company in the manufacturing industry, specializing in high-quality plastic mold parts for various industries. With a strong commitment to innovation and customer satisfaction, Plastic Mold Parts has been a leading supplier of precision plastic components for many years.The company utilizes state-of-the-art manufacturing processes and advanced technologies to produce plastic mold parts that meet the highest industry standards. With a focus on precision and quality, Plastic Mold Parts has earned a reputation for excellence in the industry.One of the key factors that sets Plastic Mold Parts apart from its competitors is its dedication to customer service. The company prides itself on providing exceptional support and guidance to its clients throughout the entire production process. From the initial design phase to the final delivery of the products, Plastic Mold Parts works closely with its customers to ensure that their specific needs and requirements are met.In addition to its commitment to superior quality and customer service, Plastic Mold Parts also places a strong emphasis on environmental sustainability. The company is dedicated to minimizing its environmental impact and has implemented various measures to reduce waste and conserve resources in its manufacturing processes. By utilizing eco-friendly materials and implementing energy-efficient practices, Plastic Mold Parts is able to deliver high-quality products while minimizing its carbon footprint.Plastic Mold Parts serves a wide range of industries, including automotive, electronics, medical, and consumer goods. The company's extensive product line includes injection molded parts, insert molded parts, overmolded parts, and custom mold components. With a focus on versatility and flexibility, Plastic Mold Parts has the capability to produce a diverse range of plastic mold parts to meet the unique needs of its clients.In recent news, Plastic Mold Parts has announced the launch of a new line of innovative plastic mold parts that are designed to enhance performance and durability. These new products have been developed in response to the evolving needs of the market and are poised to set new industry standards for quality and reliability."We are thrilled to introduce our latest line of plastic mold parts to the market," said a spokesperson for Plastic Mold Parts. "These new products represent the culmination of extensive research and development, and we are confident that they will provide our customers with exceptional value and performance."Plastic Mold Parts is committed to staying at the forefront of the industry by continually investing in research and development to bring cutting-edge solutions to its clients. The company's team of skilled engineers and technicians are dedicated to pushing the boundaries of what is possible in plastic mold part manufacturing, with a focus on innovation and excellence.As the demand for high-quality plastic mold parts continues to grow across various industries, Plastic Mold Parts remains steadfast in its commitment to delivering top-tier products and services to its clients. With a strong foundation built on quality, precision, and customer satisfaction, Plastic Mold Parts is poised to maintain its position as a leading provider of plastic mold parts for years to come.

Latest report reveals significant findings in the automotive industry

[Company Name] is a leading company in the technology industry, known for its innovation and cutting-edge products. Recently, the company has made headlines with its latest product launch, which has created a buzz in the market.The new product, [Product Name], is a game-changer in the industry, with its advanced features and capabilities. It is set to revolutionize the way people interact with technology, and has already received rave reviews from industry experts and consumers alike.The [Product Name] is designed to be sleek, stylish, and user-friendly, making it a must-have for tech enthusiasts and professionals. It boasts a range of features that set it apart from its competitors, including a powerful processor, stunning display, and long-lasting battery life. In addition, it also comes with a range of cutting-edge security features, ensuring that user data is always protected.One of the key highlights of the [Product Name] is its state-of-the-art camera system, which has been hailed as one of the best in the market. The device's high-resolution camera, combined with advanced image processing technology, ensures that users can capture stunning photos and videos with ease. Whether it's a scenic landscape or a candid portrait, the [Product Name] delivers exceptional results every time.Furthermore, the [Product Name] also offers a seamless and intuitive user experience, thanks to its advanced operating system and software. Users can enjoy a wide range of apps and services, as well as effortless connectivity with other devices. This makes the [Product Name] the perfect choice for individuals who lead a fast-paced and connected lifestyle.With its impressive performance and sleek design, the [Product Name] has already attracted a loyal following, with pre-orders and sales skyrocketing. The company has reported record-breaking figures, with demand far exceeding initial projections. This has solidified the [Product Name] as a game-changing product in the industry, with its impact being felt across the market.As a leading player in the industry, [Company Name] has a long-standing reputation for delivering innovative and high-quality products. This latest product launch is a testament to the company's commitment to pushing the boundaries of technology and delivering exceptional experiences to its customers.In addition to its impressive product lineup, [Company Name] is also known for its commitment to sustainability and corporate social responsibility. The company has implemented a range of initiatives to reduce its environmental impact and promote social good, making it a leader in its field.Looking ahead, [Company Name] is poised to continue its success in the market, with a strong pipeline of new products and innovations in the works. The company remains dedicated to its vision of empowering individuals and businesses through technology, and is committed to delivering exceptional value to its customers.The launch of the [Product Name] is a significant milestone for [Company Name], and it further cements the company's position as a leader in the technology industry. With its advanced features, sleek design, and outstanding performance, the [Product Name] is set to make a lasting impact and raise the bar for the industry as a whole.

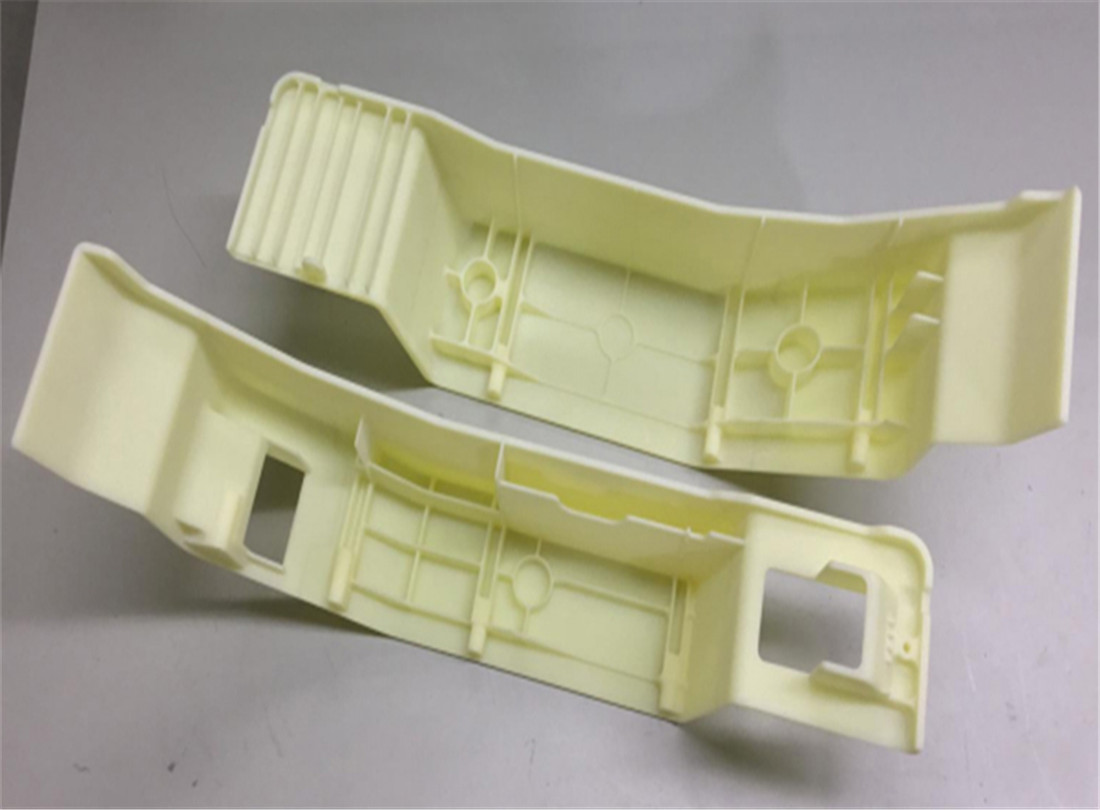

New fully functional prototype unveiled

Fully Functional Prototype Unveiled by Renowned CompanyThe renowned company, known for its innovative and cutting-edge technological advancements, has recently unveiled its latest creation - a fully functional prototype that has the potential to revolutionize the industry. This prototype represents a significant milestone for the company, as it showcases their commitment to pushing the boundaries of what is possible in the world of technology.The prototype, which has been in development for several years, is the result of the company's relentless pursuit of innovation and excellence. It represents the culmination of countless hours of research, development, and testing, and is a testament to the company's dedication to staying at the forefront of technological advancements.The prototype boasts a range of groundbreaking features that set it apart from anything else on the market. It is equipped with state-of-the-art technology that enables it to perform tasks with unprecedented efficiency and accuracy. In addition, it incorporates advanced materials and design elements that make it not only highly functional but also visually striking.One of the most impressive aspects of the prototype is its versatility. It has been designed to be adaptable to a wide range of applications, making it suitable for use in various industries. From manufacturing and construction to healthcare and transportation, the prototype has the potential to revolutionize the way that tasks are carried out in numerous fields.The unveiling of the fully functional prototype has generated significant excitement within the industry, with experts and enthusiasts alike eagerly anticipating its potential impact. Many are already speculating about the ways in which this prototype could be integrated into existing technologies and processes, and the possibilities seem endless.The company behind the prototype is no stranger to pushing the boundaries of what is possible in the world of technology. With a long history of groundbreaking innovations and a track record of success, they have earned a reputation as a leader in the industry. Their commitment to excellence and their ability to think outside the box have consistently set them apart from their peers, and the unveiling of this prototype only serves to reinforce their position at the forefront of technological advancements.In addition to its impressive technological achievements, the company is also known for its dedication to sustainability and social responsibility. They have made significant investments in developing technologies that minimize environmental impact and improve the lives of individuals and communities around the world. This commitment to making a positive difference sets them apart as a company that is not only focused on profits, but also on making the world a better place.As the fully functional prototype continues to generate excitement and speculation, the company remains focused on the next steps in its development. They are committed to refining and perfecting the prototype, with the goal of bringing it to market in the near future. In the meantime, they continue to explore new opportunities for collaboration and partnership, recognizing that the potential impact of this prototype extends far beyond their own capabilities.Overall, the unveiling of the fully functional prototype represents a significant achievement for the company and a defining moment in the world of technology. With its groundbreaking features, adaptability, and potential for revolutionizing multiple industries, it is clear that this prototype has the power to change the way we think about technology. As the company continues to push the boundaries of what is possible, the world eagerly awaits the next chapter in this exciting technological journey.

Benefits of Injection Molded Plastics for Clear Products

Clear Injection Molded Plastics has been making waves in the plastics industry with their innovative and high-quality products. The company, which was established in 1995, has quickly become a leader in the field of injection molded plastics. Their commitment to providing the highest level of service and quality has made them a go-to supplier for businesses in a wide range of industries.Clear Injection Molded Plastics specializes in creating custom plastic components for a variety of applications. Their state-of-the-art facility is equipped with the latest technology and machinery, allowing them to produce high-quality, precision-engineered products. From medical devices to automotive components, Clear Injection Molded Plastics has the capabilities to meet the needs of any customer.One of the company's most notable achievements is their development of clear injection molded plastics. This groundbreaking technology has opened up a world of possibilities for businesses looking for transparent or translucent plastic components. Clear plastics are in high demand across numerous industries, including medical, consumer goods, and electronics. Clear Injection Molded Plastics' ability to produce these components with exceptional clarity and precision has set them apart from their competitors.In addition to their commitment to quality and innovation, Clear Injection Molded Plastics also places a strong emphasis on sustainability. They have implemented several environmentally friendly practices in their manufacturing process, such as recycling and using eco-friendly materials. Their dedication to reducing their environmental impact has not gone unnoticed, and they have gained a reputation as a responsible and ethical supplier.Clear Injection Molded Plastics' success can be attributed to their team of highly skilled and experienced professionals. From design and engineering to manufacturing and quality control, every aspect of the production process is handled by knowledgeable experts. This ensures that every product that leaves their facility meets the highest standards of quality and performance.Furthermore, Clear Injection Molded Plastics is committed to providing exceptional customer service. They work closely with their clients to understand their specific needs and requirements, and then tailor their products and services to meet those needs. This level of personalized attention has earned them a loyal customer base and has helped them build long-lasting partnerships with businesses of all sizes.Looking to the future, Clear Injection Molded Plastics is poised for continued growth and success. Their investment in cutting-edge technology and their dedication to innovation will undoubtedly keep them at the forefront of the plastics industry. As the demand for high-quality, clear injection molded plastics continues to rise, Clear Injection Molded Plastics is well-positioned to capitalize on this trend and expand their market presence.In conclusion, Clear Injection Molded Plastics has established itself as a leader in the plastics industry through its commitment to quality, innovation, and sustainability. With their advanced capabilities, skilled team, and dedication to customer service, they have set themselves apart as a top supplier of custom plastic components. As they continue to grow and evolve, Clear Injection Molded Plastics is poised to remain a driving force in the industry for years to come.

Laser Engraving Eva Foam: Techniques and Applications

In the world of manufacturing and production, precision and efficiency are key factors that can make or break a business. Companies are constantly on the lookout for new technologies and methods that can help them improve their processes and deliver high-quality products to their customers. One such technology that has gained significant attention in recent years is laser engraving, and a company at the forefront of this industry is {Company Name}.{Company Name} is a leader in the field of laser engraving and has been consistently pushing the boundaries of innovation and technology in the manufacturing sector. Their state-of-the-art facilities and cutting-edge equipment have allowed them to offer a wide range of laser engraving services, including the engraving of materials such as plastic, wood, metal, and foam. However, one of their most sought-after services is the laser engraving of Eva foam.Eva foam, also known as ethylene-vinyl acetate foam, is a versatile material that is widely used in various industries, including footwear, packaging, automotive, and sports equipment. It is known for its lightweight, durable, and flexible properties, making it an ideal material for a wide range of applications. However, the traditional methods of engraving Eva foam, such as using hot stamping or cutting tools, often result in inconsistent and imprecise engravings.{Company Name}'s laser engraving technology has revolutionized the way Eva foam is engraved, offering unparalleled precision and detail that is simply not achievable through traditional methods. By using a high-powered laser beam, {Company Name} is able to precisely engrave intricate designs, logos, and patterns onto Eva foam with incredible accuracy and speed. This has opened up a whole new world of possibilities for businesses that rely on Eva foam for their products, as they can now offer custom-branded and personalized items with ease.One of the key advantages of {Company Name}'s laser engraving technology is the ability to achieve a consistent and uniform engraving depth, ensuring that the engravings are clear, sharp, and long-lasting. This level of precision is simply not attainable through traditional methods, making laser engraving the go-to choice for businesses that require high-quality engravings on Eva foam.In addition to precision, {Company Name}'s laser engraving technology also offers great efficiency and cost-effectiveness. The automated nature of laser engraving allows for quick setup and minimal material wastage, resulting in lower production costs and faster turnaround times for their clients. This not only benefits {Company Name}'s clients but also helps them stay competitive in the market by offering superior quality products at a reasonable price point.{Company Name} has also made significant investments in the development of their laser engraving technology, ensuring that they are constantly improving and expanding their capabilities. Their dedicated team of engineers and technicians are continuously exploring new techniques and applications for laser engraving Eva foam, further solidifying their position as an industry leader in this space.Looking ahead, {Company Name} is committed to continuing their research and development efforts to further enhance their laser engraving technology and offer even more advanced capabilities to their clients. With the demand for personalized and custom-branded products on the rise, the potential for laser engraving Eva foam is vast, and {Company Name} is well-positioned to capitalize on this growing market.In conclusion, {Company Name}'s laser engraving technology has revolutionized the way Eva foam is engraved, offering unparalleled precision, efficiency, and cost-effectiveness. Their commitment to innovation and dedication to pushing the boundaries of technology have positioned them as a leading provider of laser engraving services in the manufacturing industry. As the demand for high-quality, custom-branded products continues to grow, {Company Name} is well-equipped to meet the needs of their clients and drive the industry forward.

High-quality aerospace CNC machining services for precision parts

Aerospace CNC Machining, the leading provider of precision machining for the aerospace industry, has established itself as a trusted partner for companies seeking high-quality components for their aircraft and space vehicles. With a strong commitment to excellence and a dedication to customer satisfaction, Aerospace CNC Machining has become a key player in the aerospace manufacturing industry.The company, based in [location], has a state-of-the-art facility equipped with the latest CNC machining technology. This allows the company to produce complex and intricate components with the highest level of precision and accuracy. Aerospace CNC Machining's team of highly skilled engineers and machinists are experts in working with a wide range of materials, including aluminum, titanium, and stainless steel, ensuring that they can meet the specific needs of their aerospace clients.One of the key factors that sets Aerospace CNC Machining apart from its competitors is its unwavering commitment to quality. The company adheres to stringent quality control measures at every stage of the manufacturing process, from initial design to final inspection. This ensures that each component produced by Aerospace CNC Machining meets the strict standards and specifications required by the aerospace industry.In addition to its focus on quality, Aerospace CNC Machining also prioritizes efficiency and timely delivery. The company understands the fast-paced nature of the aerospace industry and works diligently to meet tight deadlines without sacrificing quality. This has earned Aerospace CNC Machining a reputation for reliability and dependability among its clients.Aerospace CNC Machining's dedication to excellence has not gone unnoticed. The company has been recognized with several industry awards for its outstanding performance and contributions to the aerospace manufacturing sector. These accolades serve as a testament to Aerospace CNC Machining's commitment to being a leader in the industry.Aerospace CNC Machining's expertise extends to a wide range of aerospace components, including aircraft engine parts, landing gear components, structural fittings, and much more. The company has the capability to handle both small-scale and large-scale production runs, making it a versatile partner for aerospace manufacturers of all sizes.Aerospace CNC Machining's customer-centric approach is another key aspect of its success. The company works closely with each client to understand their specific needs and requirements, and then develops tailored solutions to meet those needs. This personalized approach has helped Aerospace CNC Machining build strong, long-lasting relationships with its clients, many of whom consider the company a trusted partner in their supply chain.Looking ahead, Aerospace CNC Machining is focused on continuing to expand its capabilities and offerings in order to better serve the evolving needs of the aerospace industry. The company invests in ongoing research and development to stay at the forefront of technological advancements and industry trends. This commitment to innovation ensures that Aerospace CNC Machining remains a leader in the aerospace manufacturing sector for years to come.As the aerospace industry continues to grow and evolve, the demand for high-quality precision components will only increase. Aerospace CNC Machining is well-positioned to meet this demand and continue to be a valued partner for aerospace manufacturers around the world. With its relentless focus on quality, efficiency, and customer satisfaction, Aerospace CNC Machining has established itself as a driving force in the aerospace manufacturing industry and is poised for continued success in the future.

High-Quality Precision Turning Components for CNC Machining Operations

CNC Precision Turning ComponentsIn the world of manufacturing, precision is key. Products must be made with exacting accuracy in order to meet the demands of modern consumers. This is where CNC precision turning components come into play. These components are an essential part of the manufacturing process, providing the precision and accuracy needed to create high-quality products.{Company Name} is a leading provider of CNC precision turning components. With years of experience and a dedication to quality, they have become a trusted name in the industry. Their components are used in a wide range of applications, including aerospace, automotive, and medical equipment. They are capable of producing components with tight tolerances and complex geometries, making them a valuable partner for companies looking to produce top-quality products.One of the key advantages of CNC precision turning components is their ability to produce parts with minimal human intervention. The CNC (Computer Numerical Control) technology used in these components allows for highly precise and consistent production, with minimal risk of error. This not only improves the quality of the products, but also reduces the time and cost of production.{Company Name}'s CNC precision turning components are made using state-of-the-art equipment and the latest manufacturing techniques. This allows them to produce components with exceptional accuracy and reliability. Their team of skilled engineers and technicians work closely with clients to develop custom solutions for their specific needs, ensuring that the final product meets their exact specifications.In addition to their precision and reliability, {Company Name}'s CNC precision turning components are also known for their versatility. They can be used to produce a wide range of parts and components, including shafts, valves, fittings, and much more. This flexibility makes them a valuable resource for companies looking to streamline their manufacturing processes and improve their overall efficiency.The demand for CNC precision turning components continues to grow, as manufacturers seek to improve the quality and performance of their products. As a result, {Company Name} is constantly expanding and upgrading their capabilities to meet the needs of their clients. They are committed to staying at the forefront of CNC technology, ensuring that their components are always at the cutting edge of the industry.With their dedication to quality, precision, and innovation, {Company Name} has solidified their position as a leader in the field of CNC precision turning components. Their components are trusted by companies around the world to produce high-quality products with unmatched accuracy and reliability. As the demand for precision manufacturing continues to grow, {Company Name} is well-positioned to meet the needs of their clients and continue to push the boundaries of what is possible in modern manufacturing.In conclusion, CNC precision turning components are an essential part of modern manufacturing, allowing companies to produce high-quality products with exceptional precision and reliability. {Company Name} is a trusted provider of these components, with a proven track record of delivering top-quality solutions to their clients. Their dedication to innovation and quality makes them a valuable partner for companies looking to take their manufacturing processes to the next level.