Custom High Precision Turned Parts for Your Business Needs

By:Admin

{} is a renowned manufacturer of high precision turned parts, specializing in providing custom solutions for a wide range of industries. With years of experience and expertise in precision engineering, the company has become a trusted partner for businesses seeking top-notch components for their manufacturing processes.

The company's commitment to quality and innovation has set them apart in the industry. Their state-of-the-art facilities are equipped with the latest technology and machinery, allowing them to produce turned parts with unmatched precision and accuracy. Their team of skilled engineers and technicians are dedicated to ensuring that every component meets the highest standards of quality and performance.

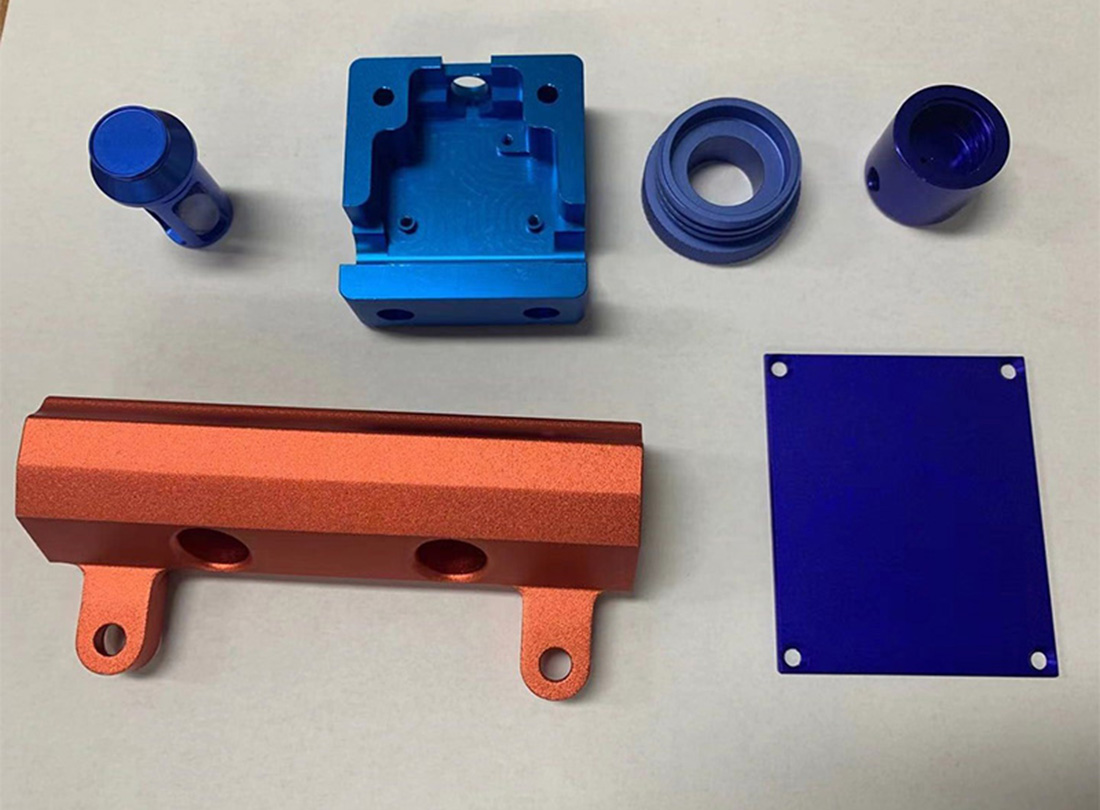

{}'s range of high precision turned parts includes a variety of custom components, including shafts, pins, connectors, and more. These parts are used in a wide range of applications, from automotive and aerospace to medical and electronics. The company works closely with each of their clients to understand their specific needs and requirements, and then delivers tailor-made solutions that meet or exceed expectations.

In addition to their precision engineering capabilities, {} prides itself on their commitment to customer service. They understand the importance of delivering products on time and within budget, and strive to maintain clear communication with their clients throughout the manufacturing process. This dedication to customer satisfaction has earned them a loyal and satisfied customer base.

Furthermore, {} is dedicated to sustainability and environmental responsibility in their manufacturing processes. They have implemented eco-friendly practices in their facilities, such as reducing waste and energy consumption, and recycling materials whenever possible. This commitment to sustainability aligns with the company's values of integrity and corporate social responsibility.

As the demand for high precision turned parts continues to grow, {} is poised to remain at the forefront of the industry. Their reputation for excellence, combined with their dedication to innovation and customer service, positions them as a leading provider of precision components for a wide range of manufacturing applications.

In conclusion, {}'s high precision turned parts are a testament to their commitment to quality, innovation, and customer satisfaction. As the manufacturing industry continues to evolve, this company will undoubtedly remain a key player in delivering top-quality components to businesses worldwide. With their state-of-the-art facilities, skilled team, and dedication to sustainability, {} is well-equipped to meet the growing demand for high precision turned parts now and in the future.

Company News & Blog

Custom Precision Turned Parts: A Complete Guide to Machined Components

Precision Turned Parts (PTP) is a leading manufacturer of high-quality turned parts for various industries. With a focus on precision and quality, PTP has been serving its customers with top-notch products for several years.Based in (location), PTP has a state-of-the-art facility that is equipped with the latest technology and machinery to produce turned parts with exact specifications. The company has a team of highly skilled and experienced engineers and technicians who are dedicated to delivering precision turned parts that meet the unique requirements of each customer.PTP offers a wide range of turned parts, including shafts, connectors, nuts, bolts, and many other custom components. The company has the capability to work with various materials such as aluminum, stainless steel, brass, and plastics, ensuring that they can cater to a diverse clientele.In addition to its extensive manufacturing capabilities, PTP also provides value-added services such as design assistance, prototyping, and assembly. This comprehensive approach allows the company to serve as a one-stop solution for all turned part needs.One of the key factors that set PTP apart from its competitors is its commitment to quality. The company adheres to strict quality control measures at every stage of the manufacturing process, ensuring that each turned part meets the highest standards. PTP is also certified to ISO 9001, further demonstrating its dedication to excellence.Furthermore, PTP is dedicated to staying at the forefront of its industry by investing in research and development. The company continuously explores new technologies and processes to improve its manufacturing capabilities and offer innovative solutions to its customers.PTP's commitment to quality, precision, and innovation has earned the trust and loyalty of its customers. The company has built strong, long-term relationships with clients from various industries, including automotive, aerospace, medical, and telecommunications.With a proven track record of delivering top-quality turned parts and exceptional customer service, PTP has established itself as a trusted partner for companies seeking reliable manufacturing solutions.In recent news, PTP has announced the addition of a new state-of-the-art CNC lathe to its production facility. This investment in advanced machining technology will further enhance the company's capabilities and allow it to meet the increasing demand for precision turned parts.The new CNC lathe boasts high-speed and high-precision machining capabilities, which will enable PTP to produce turned parts with even tighter tolerances and faster turnaround times. This acquisition aligns with PTP's commitment to staying ahead of the curve and providing its customers with the best possible solutions."We are excited to add this cutting-edge CNC lathe to our facility," said [Company Spokesperson]. "This investment reflects our dedication to meeting the evolving needs of our customers and maintaining our position as a leader in the turned parts industry."The addition of the new CNC lathe is just one example of PTP's ongoing efforts to improve its manufacturing capabilities and ensure customer satisfaction. The company remains focused on delivering top-quality turned parts that meet the highest standards of precision and reliability.As PTP continues to grow and innovate, it remains committed to its core values of quality, precision, and customer service. The company's unwavering dedication to excellence positions it as a preferred partner for businesses seeking reliable and high-quality turned part solutions. With its state-of-the-art facility, experienced team, and strong track record, PTP is poised to continue making a significant impact in the manufacturing industry.

Top Techniques for Laser Cutting Polyethylene Foam

Polyethylene Foam Laser Cutting: A Game-Changer in the Packaging IndustryIn the ever-evolving world of packaging, finding innovative and efficient ways to create protective and attractive packaging solutions is crucial. One such innovation is the use of polyethylene foam laser cutting, which has revolutionized the way packaging materials are fabricated. In this article, we'll explore the benefits of polyethylene foam laser cutting and how it has become a game-changer in the packaging industry.Polyethylene foam is a popular material choice for packaging due to its excellent cushioning and thermal insulation properties. It is widely used in various industries, including electronics, medical devices, automotive, and consumer goods. However, traditional methods of cutting and shaping polyethylene foam, such as die cutting and waterjet cutting, have limitations in terms of precision, speed, and flexibility.This is where polyethylene foam laser cutting comes in. By harnessing the power of laser technology, manufacturers can now achieve intricate and precise cuts on polyethylene foam with ease. This process involves using a high-powered laser to vaporize the foam material along a pre-programmed path, resulting in clean and precise cuts without the need for tooling or physical contact.The benefits of polyethylene foam laser cutting are manifold. Firstly, it allows for the creation of complex and intricate designs that were previously unachievable with traditional cutting methods. This opens up a world of possibilities for creative and custom packaging solutions, enabling companies to differentiate their products and enhance their brand image.Secondly, polyethylene foam laser cutting is a highly efficient process. With the ability to cut through foam materials at high speeds and with minimal material wastage, manufacturers can optimize production processes and reduce manufacturing costs. Additionally, the non-contact nature of laser cutting eliminates the need for additional finishing processes, saving both time and resources.Moreover, polyethylene foam laser cutting offers superior precision and consistency. Unlike manual cutting methods, laser cutting ensures that each piece of foam is cut to the exact specifications, resulting in uniform and high-quality packaging materials. This is crucial for protecting delicate and valuable products during transit and storage.At {}, we have been at the forefront of integrating polyethylene foam laser cutting into our packaging solutions. With our state-of-the-art laser cutting equipment and expertise in materials engineering, we are able to deliver tailor-made packaging solutions that meet the unique requirements of our clients. Our commitment to innovation and quality has made us a trusted partner for companies seeking cutting-edge packaging solutions.One of the key advantages of partnering with {} is our ability to provide customized packaging solutions that are both visually appealing and highly functional. By leveraging polyethylene foam laser cutting, we can create packaging designs that are tailored to each product's specifications, ensuring a perfect fit and maximum protection. This level of customization not only enhances the aesthetic appeal of the packaging but also reinforces the brand identity of our clients.In addition to our expertise in polyethylene foam laser cutting, {} is dedicated to sustainability and environmental responsibility. Our foam materials are sourced from reputable suppliers and are recyclable, contributing to a circular economy and reducing environmental impact. By choosing {} as a packaging partner, companies can align with their sustainability goals without compromising on packaging performance.In conclusion, polyethylene foam laser cutting has emerged as a game-changer in the packaging industry, offering unparalleled precision, efficiency, and customization. As companies continue to demand innovative and sustainable packaging solutions, the adoption of laser cutting technology will undoubtedly become more prevalent. With our expertise in polyethylene foam laser cutting and dedication to quality and sustainability, {} is well-positioned to meet the evolving needs of the packaging market and deliver exceptional packaging solutions for our clients.

Custom CNC Drilling Services for Precision Machining

CNC Drilling Services: Revolutionizing the Manufacturing IndustryIn today's fast-paced and competitive manufacturing industry, precision and efficiency are paramount. Manufacturers are constantly seeking new and innovative ways to improve their processes and deliver high-quality products to their customers. One technology that has revolutionized the manufacturing industry is CNC drilling services.CNC drilling, or computer numerical control drilling, is a modern machining process that utilizes automated machinery to produce precise and accurate holes in materials such as metal, plastic, and wood. This technology has significantly improved the efficiency and reliability of drilling processes, making it an essential tool for manufacturers across various industries.One company at the forefront of CNC drilling services is {}, a leading provider of precision machining and manufacturing solutions. With state-of-the-art equipment and a team of highly skilled engineers and technicians, {} has established itself as a trusted partner for businesses seeking high-quality drilling services.{}'s CNC drilling services offer a wide range of capabilities, including drilling, tapping, and countersinking, with the ability to produce complex hole patterns and geometries with exceptional accuracy. The company's advanced CNC machinery allows for rapid production turnaround times, making it an ideal solution for both prototyping and high-volume production runs.One of the key advantages of {}'s CNC drilling services is their ability to consistently deliver tight tolerances and high-quality finishes, ensuring that components and parts meet the most demanding specifications. This level of precision is essential for industries such as aerospace, automotive, medical, and electronics, where even the smallest deviation can have significant consequences.In addition to precision drilling, {} offers a range of value-added services to support their customers' diverse manufacturing needs. These services include design assistance, material selection guidance, and finishing processes such as anodizing, plating, and painting. By providing a comprehensive suite of services, {} can serve as a one-stop shop for manufacturers looking to streamline their production processes.With a commitment to continuous improvement and investment in the latest technology, {} has positioned itself as a leader in the CNC drilling services industry. The company's dedication to quality, reliability, and customer satisfaction has earned them a strong reputation in the market, attracting a diverse customer base across various sectors.Beyond delivering high-quality products, {} is also focused on sustainability and environmental responsibility. The company actively seeks ways to minimize waste, reduce energy consumption, and utilize eco-friendly materials and processes wherever possible. By aligning their operations with sustainable practices, {} aims to not only meet the needs of their customers but also contribute to a greener and more responsible manufacturing industry.As the manufacturing industry continues to evolve, the demand for precision machining and drilling services will only grow. With its advanced capabilities, commitment to excellence, and customer-focused approach, {} is well-positioned to meet the evolving needs of manufacturers and drive innovation in the CNC drilling services space.In conclusion, CNC drilling services have become a cornerstone of modern manufacturing, enabling businesses to produce high-quality components with unparalleled precision and efficiency. Companies like {} are leading the way in delivering cutting-edge drilling solutions, and their dedication to quality, innovation, and sustainability will undoubtedly shape the future of the manufacturing industry.

Precision CNC Machining for Aerospace Industry: A Crucial Component for Aircraft Manufacturing

Aerospace CNC Machining Technology Advances to New HeightsIn the ever-evolving aerospace industry, precision and innovation are paramount. As manufacturers and designers continue to push the boundaries of what is possible in aerospace technology, the demand for advanced machining solutions has never been greater. This is where the cutting-edge technology of CNC (Computer Numerical Control) machining comes into play.CNC machining is a process that utilizes computerized controls to operate and manipulate machine tools for precise cutting and shaping of aerospace components. The technology has revolutionized the manufacturing process by enabling the production of highly complex and intricate parts with unparalleled accuracy and repeatability.One company at the forefront of this technological revolution is {}. With a strong focus on innovation and precision engineering, they have established themselves as a leader in the aerospace CNC machining industry. Their state-of-the-art facilities and advanced machining capabilities have allowed them to cater to the needs of some of the most demanding aerospace projects.Founded on the principles of quality, reliability, and innovation, {} has continuously invested in cutting-edge technology and skilled personnel to stay ahead of the curve. Their expertise in CNC machining has enabled them to produce components with incredibly tight tolerances and complex geometries, meeting the stringent requirements of the aerospace industry.The aerospace sector demands the highest standards of quality and performance, and {} has risen to the challenge by incorporating advanced CNC machining technologies into their production processes. By leveraging the latest software and hardware innovations, they have been able to optimize machining operations, reduce lead times, and enhance overall quality control.One of the key advantages of CNC machining in the aerospace industry is its ability to handle a wide range of materials, including aluminum, titanium, stainless steel, and high-temperature alloys. This versatility allows aerospace manufacturers to produce components that are not only lightweight but also capable of withstanding the extreme conditions experienced during flight.Furthermore, with the increasing focus on sustainability and fuel efficiency, aerospace companies are constantly seeking ways to reduce the weight of their aircraft. CNC machining plays a crucial role in this endeavor by enabling the production of lightweight components without compromising on strength or performance.In addition to its manufacturing capabilities, {} has also established itself as a trusted partner in the realm of aerospace engineering and design. With a team of experienced engineers and technicians, they are able to collaborate with aerospace OEMs and Tier 1 suppliers to optimize component designs for manufacturability, cost-effectiveness, and performance.As the aerospace industry continues to evolve, the demand for more advanced and efficient machining solutions will only intensify. {} is well-positioned to meet these demands with their commitment to continuous improvement and investment in cutting-edge CNC machining technology.In conclusion, the advancement of aerospace CNC machining technology is reshaping the way aerospace components are manufactured. With companies like {} leading the charge, the industry is poised to achieve new heights of precision, efficiency, and innovation. As the aerospace sector looks towards the future, CNC machining will undoubtedly play a pivotal role in shaping the next generation of aircraft and spacecraft.

Complete Guide to Mold Plastic Injection: Everything You Need to Know

Mold Plastic Injection company specializes in providing high-quality plastic injection molding services for a wide range of industries. With their state-of-the-art facilities and expert team, they have earned a reputation for delivering precision, efficiency, and reliability. Recently, the company announced a new partnership with a leading manufacturer, paving the way for expanded capabilities and even greater service offerings.The partnership will allow Mold Plastic Injection to access advanced technology and resources, further enhancing their ability to meet the diverse needs of their clients. This development comes as part of the company's ongoing commitment to staying at the forefront of industry innovation and ensuring that they are equipped to handle complex projects with the utmost precision and efficiency.The company's dedication to quality and customer satisfaction has positioned them as a trusted partner for businesses seeking plastic injection molding solutions. Their team of experienced professionals works closely with clients to understand their unique requirements and deliver customized manufacturing solutions that meet and exceed expectations.The newly formed partnership will enable Mold Plastic Injection to expand their capabilities in several key areas, including the production of larger and more intricate molds. Additionally, the company will be able to offer a broader range of materials, opening up new possibilities for clients in industries such as automotive, aerospace, consumer goods, and more.As a result of this partnership, Mold Plastic Injection has announced plans to invest in new machinery and technology, ensuring that they remain at the forefront of plastic injection molding innovation. This investment will further solidify their position as a leading provider of high-quality, precision-molded components.The company's dedication to excellence extends beyond their manufacturing capabilities. Mold Plastic Injection is committed to sustainable practices and environmental stewardship. They strive to minimize waste and energy consumption while maximizing efficiency and productivity. With this in mind, the company continues to explore opportunities to reduce their environmental impact and contribute to a more sustainable future.In addition to their commitment to quality and environmental responsibility, Mold Plastic Injection places a strong emphasis on customer service. They maintain open lines of communication with clients throughout the manufacturing process, ensuring that their needs are met every step of the way. The company's focus on building long-term, collaborative partnerships has solidified their reputation as a reliable and trusted provider of plastic injection molding services.With their new partnership and expanded capabilities, Mold Plastic Injection is poised to continue delivering exceptional results for clients across a wide range of industries. Their relentless pursuit of excellence, commitment to innovation, and dedication to customer satisfaction set them apart as a leader in the plastic injection molding industry.As the company looks to the future, they remain focused on exceeding the expectations of their clients and driving continued growth and success. With their expanded capabilities and unwavering commitment to quality, Mold Plastic Injection is ready to take on new challenges and deliver even greater value to their customers.

Top Techniques for Sheet Metal Bending

[Company Name] is a leading provider of sheet metal bending solutions for a wide range of industries. The company has established a strong reputation for its expertise in precision bending and forming of sheet metal, using advanced technologies and state-of-the-art machinery to deliver high-quality products to its customers.Sheet metal bending is a critical process in the manufacturing of various products, ranging from automotive components and aerospace parts to household appliances and electronic devices. It involves the deformation of a metal sheet into a desired shape or form by applying force through a press brake or other bending equipment. Precision and accuracy are essential in sheet metal bending to ensure that the final product meets the required specifications and standards.With years of experience and technical know-how, [Company Name] has developed a comprehensive range of sheet metal bending capabilities to cater to diverse customer needs. The company's team of skilled engineers and technicians work closely with clients to understand their specific requirements and provide tailored solutions that meet their expectations.One of the key strengths of [Company Name] is its investment in advanced bending machinery and equipment. The company utilizes cutting-edge press brakes with computer numerical control (CNC) technology, which enables precise control of the bending process and the ability to produce complex shapes with high accuracy. This capability allows [Company Name] to handle a wide variety of metal materials, including aluminum, steel, stainless steel, and titanium, among others, in varying thicknesses.In addition to its technical expertise, [Company Name] places a strong emphasis on quality and efficiency in its sheet metal bending operations. The company adheres to strict quality control measures throughout the production process, ensuring that every bent component meets the highest standards of precision and consistency. By implementing lean manufacturing principles and optimizing its workflows, [Company Name] is able to deliver cost-effective solutions without compromising on quality.Furthermore, [Company Name] is committed to staying at the forefront of industry developments and innovation in sheet metal bending. The company continuously invests in research and development to explore new techniques, materials, and technologies that can further enhance its bending capabilities and offer added value to its customers. By staying ahead of the curve, [Company Name] is able to meet the evolving needs of the market and provide cutting-edge solutions for challenging bending applications.As a reliable partner for sheet metal bending, [Company Name] serves a diverse customer base across various industries, including automotive, aerospace, electronics, and manufacturing. The company's ability to handle both small-scale and large-scale production runs makes it a preferred choice for businesses seeking high-quality and cost-effective bending solutions.In conclusion, [Company Name] continues to set the standard for excellence in sheet metal bending, driven by its commitment to precision, quality, and innovation. With its extensive capabilities, state-of-the-art machinery, and dedicated team, the company is well-positioned to meet the complex bending needs of today's manufacturing landscape and deliver value-added solutions to its customers.For more information about [Company Name] and its sheet metal bending services, please visit [company website] or contact the company directly at [contact information].

The Benefits of Rapid Prototyping CNC Machining for Your Business

In the world of manufacturing, the process of rapid prototyping has revolutionized the way products are designed and developed. Rapid prototyping, also known as 3D printing, allows companies to quickly and cost-effectively produce prototypes of their products, helping them to test and validate their designs before full-scale production. One company that is at the forefront of this technology is [company name].[Company name] is a leading provider of rapid prototyping and CNC machining services, offering a wide range of solutions to meet the needs of its clients. With state-of-the-art equipment and a team of experienced professionals, [company name] is able to provide high-quality prototypes and production parts with fast turnaround times.The company’s rapid prototyping services include 3D printing, stereolithography, selective laser sintering, and fused deposition modeling, among others. These technologies allow [company name] to produce accurate and functional prototypes in a matter of hours, helping its clients to reduce their time to market and lower their development costs.In addition to its rapid prototyping services, [company name] also offers CNC machining, a process that uses computer-controlled machines to produce precision parts from various materials. With a wide range of CNC machining capabilities, including milling, turning, and multi-axis machining, [company name] is able to meet the diverse needs of its clients, from simple prototypes to complex production parts.One of the key differentiators of [company name] is its ability to work with a wide range of materials, including plastics, metals, and composites. This allows the company to provide its clients with a comprehensive solution for their prototyping and production needs, regardless of the materials they require.The company’s dedication to quality and customer satisfaction sets it apart from its competitors. With a rigorous quality control process and a commitment to meeting the unique requirements of each project, [company name] has built a reputation for delivering superior products and services to its clients.Furthermore, [company name] places a strong emphasis on innovation and continuous improvement. The company invests in the latest technologies and equipment to ensure that it remains at the forefront of the industry, allowing it to offer cutting-edge solutions to its clients.The company’s customer-centric approach is evident in its dedication to providing personalized service and support to each client. Whether a client requires rapid prototyping for a new product design or CNC machining for a production part, [company name] works closely with them to understand their specific needs and deliver a solution that meets or exceeds their expectations.[Company name] has established itself as a trusted partner for companies in a wide range of industries, including aerospace, automotive, medical, and consumer products. Its ability to deliver high-quality prototypes and production parts with fast turnaround times has made it a preferred choice for many leading companies.As the manufacturing industry continues to evolve, the demand for rapid prototyping and CNC machining services is expected to grow. With its comprehensive capabilities, dedication to quality, and commitment to innovation, [company name] is well-positioned to meet this demand and continue to be a leader in the industry.In conclusion, [company name] is a company that is setting new standards in rapid prototyping and CNC machining. With its advanced technologies, diverse capabilities, and customer-centric approach, [company name] is helping its clients to bring their products to market faster and more cost-effectively. As the industry evolves, [company name] remains committed to providing cutting-edge solutions and superior service to its clients, solidifying its position as a trusted partner in the manufacturing industry.

Precision CNC Machining for Aerospace Parts: A Complete Guide

In the world of aerospace manufacturing, precision and quality are of utmost importance. As the demand for aerospace parts continues to grow, companies are constantly seeking ways to improve their machining processes to meet the high standards required for aerospace components. The use of CNC machining has become increasingly popular in the aerospace industry due to its ability to produce high precision parts with tight tolerances. One company at the forefront of this technology is {Company Name}.{Company Name} has been a leading provider of CNC machining services for aerospace parts for over a decade. With a commitment to quality and excellence, the company has established itself as a reliable partner for aerospace manufacturers around the world. Specializing in the production of complex and intricate components, {Company Name} has the expertise and capabilities to meet the demands of the aerospace industry.Utilizing state-of-the-art CNC machining equipment, {Company Name} is able to manufacture a wide range of aerospace parts, including engine components, landing gear parts, and structural components. The company's team of highly skilled machinists and engineers work closely with clients to understand their specific requirements and develop tailored solutions to meet their needs. Whether it's a single prototype or a large production run, {Company Name} has the capabilities to deliver high-quality aerospace parts on time and within budget.One of the key advantages of CNC machining is its ability to produce parts with incredibly tight tolerances. This is crucial in the aerospace industry, where components need to meet strict specifications to ensure safety and reliability. {Company Name}'s state-of-the-art CNC machines are capable of achieving precision of up to 0.001mm, allowing for the production of extremely accurate and consistent parts. This level of precision is essential for aerospace components that are subjected to extreme conditions and high stress levels.In addition to precision, CNC machining also offers versatility in the types of materials that can be used. {Company Name} has the capabilities to machine a wide range of aerospace-grade materials, including aluminum, titanium, stainless steel, and various high-performance alloys. This flexibility allows the company to cater to the diverse needs of aerospace manufacturers and produce a wide variety of components for different applications.Furthermore, {Company Name} places a strong emphasis on quality control throughout the machining process. The company utilizes advanced inspection equipment and techniques to ensure that every part meets the highest standards of accuracy and quality. From initial design to final inspection, {Company Name} is committed to delivering aerospace parts that meet or exceed the stringent requirements of the industry.As the aerospace industry continues to evolve and demand for high-quality parts grows, {Company Name} remains dedicated to staying at the forefront of CNC machining technology. The company regularly invests in the latest CNC machines and software to enhance its capabilities and offer innovative solutions to its clients. By combining cutting-edge technology with a team of experienced professionals, {Company Name} is well-positioned to meet the evolving needs of the aerospace industry and continue to be a trusted partner for aerospace manufacturers.In conclusion, {Company Name} is a leading provider of CNC machining services for aerospace parts, offering a combination of precision, quality, and versatility to meet the demands of the aerospace industry. With a focus on innovation and continuous improvement, the company is well-equipped to tackle the challenges of modern aerospace manufacturing and deliver reliable solutions to its clients. With a dedication to excellence and a commitment to customer satisfaction, {Company Name} is poised to remain a key player in the aerospace machining industry for years to come.

Durable and Flexible Adhesive Rubber Bumper Strip for Your Needs

Adhesive Rubber Bumper Strip (name removed) - The Perfect Solution for Product ProtectionIn today's fast-paced and dynamic world, where industries are constantly evolving and developing innovative products, it has become more important than ever to ensure the safety and protection of these products. Whether it's electronic devices, furniture, or machinery, product manufacturers are constantly seeking ways to safeguard their products from damage and ensure a seamless customer experience.This is where (company name removed) comes in. With a strong focus on providing high-quality product protection solutions, (company name removed) has developed a range of innovative adhesive rubber bumper strips that are designed to provide effective protection for a wide variety of products.Established in (year removed), (company name removed) has been at the forefront of the industry, consistently delivering cutting-edge solutions that meet the ever-changing needs of its clients. The company's dedication to quality and innovation has earned it a reputation as a trusted and reliable partner for businesses seeking effective product protection solutions.The adhesive rubber bumper strips offered by (company name removed) are designed to be versatile and customizable, making them suitable for a wide range of applications. Whether it's used to protect the edges of electronic devices or to provide cushioning for furniture, these bumper strips are engineered to provide durable and reliable protection.The key to the effectiveness of these bumper strips lies in their material and design. Made from high-quality rubber, they are able to withstand the rigors of daily use, providing long-lasting protection for the products they are applied to. Additionally, their adhesive backing ensures easy and secure installation, making them a practical and convenient solution for manufacturers.One of the key advantages of (company name removed)'s adhesive rubber bumper strips is their ability to absorb shock and impact, effectively preventing damage to the products they protect. This is particularly important in industries where products are frequently moved, transported, or handled, as it helps to minimize the risk of damage during these activities.Furthermore, the customizable nature of these bumper strips allows businesses to tailor their protection solutions to the specific needs of their products. Whether it's choosing the right size, shape, or color, (company name removed) offers a range of options to ensure that its customers can find the perfect solution for their requirements.In addition to providing outstanding product protection solutions, (company name removed) also places a strong emphasis on customer satisfaction. The company's team of dedicated professionals are committed to working closely with their clients to understand their needs and provide tailored solutions that meet their exact specifications.As a company with a strong focus on innovation, (company name removed) is constantly looking for ways to enhance its product protection solutions. This commitment to improvement has led to the development of new and advanced bumper strip designs that offer even greater levels of protection and performance.With a proven track record of delivering exceptional product protection solutions, (company name removed) has established itself as a leader in the industry. Its commitment to quality, innovation, and customer satisfaction sets it apart as a trusted partner for businesses seeking reliable and effective protection solutions for their products.In conclusion, the adhesive rubber bumper strips offered by (company name removed) are a perfect solution for businesses looking to enhance the safety and protection of their products. With their durable construction, customizable design, and capacity to absorb shock and impact, these bumper strips offer an effective and practical way to safeguard a wide range of products. As (company name removed) continues to innovate and develop new solutions, it remains at the forefront of the industry, setting the standard for high-quality product protection.

Ultimate Guide to Laser Cutting Polyethylene Foam: Everything You Need to Know

Laser Cutting Polyethylene Foam Revolutionizes Packaging IndustryIn today's fast-paced world, businesses are constantly seeking innovative solutions to improve their products and services. One company at the forefront of this innovation is {Company name}, a leading provider of advanced packaging solutions. Recently, {Company name} has introduced a groundbreaking method for cutting polyethylene foam with laser technology, a game-changing development that is set to revolutionize the packaging industry.Polyethylene foam is widely used in packaging due to its lightweight, durable, and versatile nature. It is commonly utilized for cushioning and protecting a wide range of products during transit and storage. However, traditional methods of cutting and shaping polyethylene foam often involve time-consuming processes that are not always precise or cost-effective.{Company name} saw an opportunity to enhance the efficiency and quality of polyethylene foam cutting by leveraging state-of-the-art laser technology. By integrating laser cutting systems into their production process, they have achieved unparalleled precision, speed, and flexibility in shaping polyethylene foam, setting a new standard for the industry.The advanced laser cutting technology utilized by {Company name} allows for intricate designs and complex patterns to be effortlessly and accurately cut into polyethylene foam, providing a level of customization and detail that was previously unattainable. This capability opens up a world of possibilities for packaging designers and manufacturers, enabling them to create unique and tailored solutions to meet the specific needs of their products and customers.In addition to its precision and flexibility, laser cutting polyethylene foam offers environmental benefits as well. The process produces minimal waste and emissions, contributing to a more sustainable and eco-friendly approach to packaging production. As sustainability continues to be a key focus for businesses across the globe, this innovation aligns with the growing demand for environmentally responsible solutions.{Company name}'s investment in laser cutting technology for polyethylene foam underscores its commitment to providing cutting-edge packaging solutions to its clients. With a strong emphasis on innovation and continuous improvement, the company is dedicated to staying ahead of the curve and meeting the evolving needs of the packaging industry.This latest development further solidifies {Company name} as a leader in the packaging sector, building on its track record of delivering high-quality products and exceptional customer service. With a focus on collaboration and partnership, {Company name} works closely with its clients to understand their unique challenges and requirements, offering innovative solutions that add value and drive success.Furthermore, by incorporating laser cutting technology, {Company name} is not only enhancing the capabilities of its own manufacturing processes but also providing its clients with a competitive advantage in the market. The ability to create distinct and tailored packaging solutions through laser-cut polyethylene foam sets them apart from the competition, enabling them to stand out and make a lasting impression on their customers.Moving forward, {Company name} envisions continued advancements in laser cutting technology for polyethylene foam, ushering in a new era of possibilities for the packaging industry. With a focus on research and development, the company aims to push the boundaries of what is achievable, seeking to innovate and refine its processes to better serve its clientele.In conclusion, {Company name}'s introduction of laser cutting polyethylene foam represents a significant milestone for the packaging industry. With its unrivaled precision, flexibility, and environmental benefits, this advancement is poised to reshape the way packaging is designed and manufactured. As businesses strive to differentiate themselves in the market, the ability to leverage laser-cut polyethylene foam for customized and sustainable packaging solutions will undoubtedly be a game-changer. As {Company name} continues to lead the way in innovation, the future of packaging looks brighter than ever.