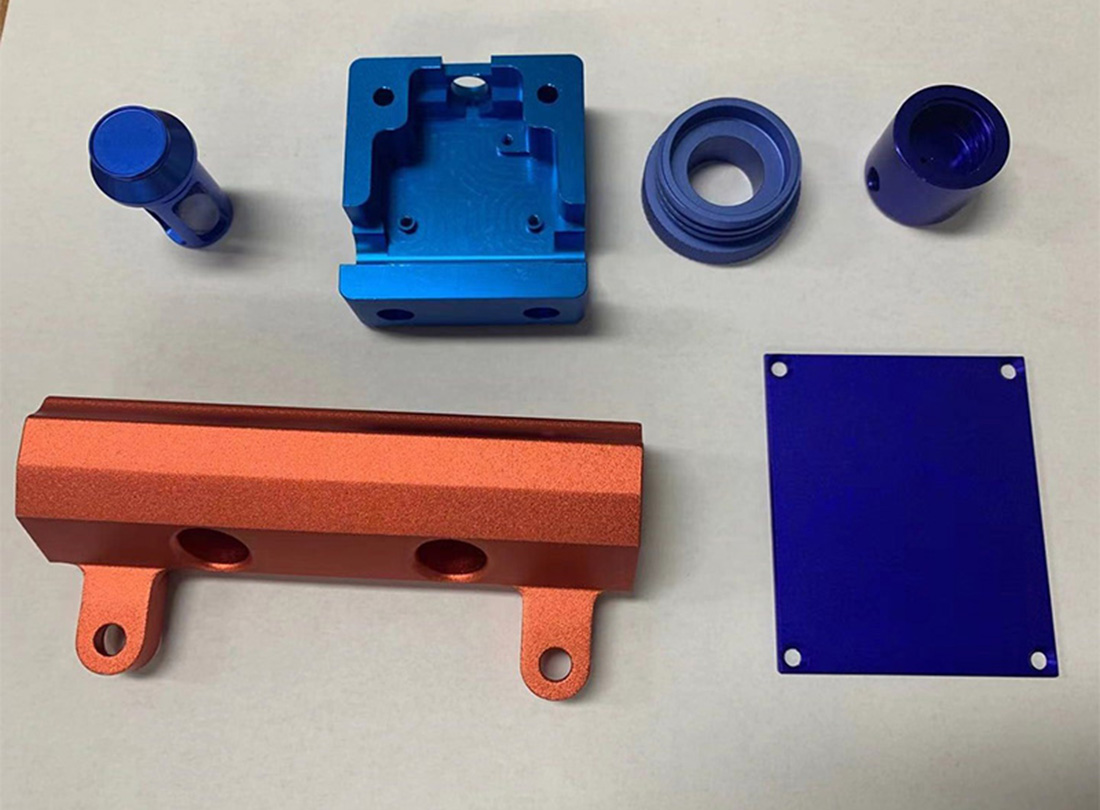

High-Quality CNC Machined Components for Precision Engineering

By:Admin

Since its establishment in [year], Precision CNC Machined Components Company has built a solid reputation for delivering precision-engineered parts that meet the highest standards of quality and performance. The company's state-of-the-art facility is equipped with the latest CNC machining technology, including multi-axis milling and turning centers, as well as advanced inspection and quality control systems. This allows the company to produce complex parts with tight tolerances and deliver them to its customers within tight deadlines.

The expansion of Precision CNC Machined Components Company's operations is seen as a strategic move to better serve its growing customer base and to position the company as a leading supplier of precision-machined components in the industry. The company's commitment to investing in the latest technology and infrastructure demonstrates its dedication to maintaining its competitive edge and meeting the evolving needs of its customers.

"We are excited to announce the expansion of our operations as it reflects our commitment to meeting the growing demand for our products," said [spokesperson], CEO of Precision CNC Machined Components Company. "Our investment in new equipment and facilities will enable us to increase our production capacity and improve our efficiency, allowing us to better serve our customers and take on new opportunities in the market."

The expansion includes the addition of [number] new CNC machining centers, as well as the expansion of the company's facility to accommodate the new equipment and provide space for future growth. The investment in new machinery will not only increase the company's production capacity but also enhance its capabilities to produce a wider range of components, including complex and intricate parts that require high precision and tight tolerances.

Furthermore, Precision CNC Machined Components Company is also investing in its workforce by hiring additional skilled machinists and technicians to operate the new equipment and maintain the highest standards of quality and precision. The company's dedication to hiring and training top talent will ensure that it continues to deliver high-quality products that meet the stringent requirements of its customers.

In addition to expanding its operations, Precision CNC Machined Components Company is also focused on enhancing its customer service and support capabilities. The company is strengthening its sales and customer support teams to provide personalized assistance to its clients and ensure that their specific needs are met. This customer-centric approach is an integral part of the company's business philosophy and will further solidify its reputation as a trusted and reliable partner for precision-machined components.

As the demand for precision-machined components continues to grow across various industries, Precision CNC Machined Components Company is well-positioned to capitalize on the opportunities in the market. With its expanded operations, investment in new technology, and commitment to customer satisfaction, the company is poised to strengthen its position as a leading provider of high-quality CNC machined parts and components.

"We are confident that our expanded operations will enable us to better serve our customers and meet the increasing demand for our products," added [spokesperson]. "With our investment in new equipment, facilities, and talent, we are ready to take on new challenges and opportunities in the market, and we look forward to continuing to provide our customers with the high-quality precision-machined components they have come to expect from us.

Company News & Blog

High-Quality Plastic Injection Tooling: What You Need to Know

Plastic Injection Tooling, a key component in the manufacturing process for a wide range of products, is a critical part of the production line for many companies. It is essential for creating high-quality, precision-engineered plastic components that are used in various industries such as automotive, aerospace, medical, consumer goods, and more. With the market demand for plastic injection tooling on the rise, it's important for companies to have access to reliable and efficient tools that can meet their production needs.{Company Name} is a leading provider of plastic injection tooling solutions, offering a wide range of services to help companies optimize their production processes. From design and engineering to prototype development and mass production, {Company Name} delivers high-quality, cost-effective solutions to meet the unique needs of each customer. With a team of experienced engineers and state-of-the-art facilities, {Company Name} is committed to providing top-notch plastic injection tooling that exceeds customer expectations.One of the key advantages of {Company Name}'s plastic injection tooling solutions is their ability to work with a variety of materials, including traditional thermoplastics, engineering resins, and high-performance materials. This flexibility allows customers to choose the best material for their specific application, whether it's for a high-stress automotive component or a delicate medical device. {Company Name} also offers expertise in designing complex tooling systems that can produce intricate parts with tight tolerances, giving customers the confidence that their products will meet the highest quality standards.In addition to their technical expertise, {Company Name} prides itself on its commitment to customer service and satisfaction. Their team works closely with each customer to understand their unique requirements and objectives, providing personalized solutions that meet their needs and budget. Whether it's a small prototype run or a large-scale production project, {Company Name} is dedicated to delivering the right plastic injection tooling solution on time and within budget.{Company Name} has also invested in cutting-edge technology and equipment to ensure that they stay at the forefront of the industry. Their state-of-the-art manufacturing facilities are equipped with the latest CNC machines, EDM equipment, and mold flow analysis software, allowing them to produce high-quality tooling with precision and efficiency. This technology, combined with their team's expertise, enables {Company Name} to deliver top-notch plastic injection tooling solutions that help their customers stay competitive in the marketplace.As the demand for plastic injection tooling continues to grow, {Company Name} remains committed to innovation and continuous improvement. They are constantly exploring new materials, technologies, and processes to enhance their capabilities and deliver better value to their customers. By staying ahead of industry trends and investing in the latest tools and equipment, {Company Name} aims to remain a trusted partner for companies looking for reliable and efficient plastic injection tooling solutions.Overall, the continued success of {Company Name} is a testament to their dedication to quality, innovation, and customer satisfaction. As the demand for plastic injection tooling continues to rise, companies can rely on {Company Name} to deliver the high-quality, cost-effective solutions they need to stay competitive in the marketplace. With their expertise, state-of-the-art facilities, and commitment to excellence, {Company Name} is well-positioned to meet the evolving needs of the industry and continue to be a leader in the plastic injection tooling market.

Top Plastic Mold Manufacturing Company Offers Quality Molds for Various Industries

Pla Plastic Molds, a leading manufacturer of plastic molds, has recently made a significant impact in the industry with their innovative and high-quality products. The company, known for its commitment to excellence and customer satisfaction, has been a key player in the plastic manufacturing industry for over two decades.Pla Plastic Molds specializes in the design and production of custom plastic molds for a wide range of applications, including automotive parts, consumer goods, electronics, and medical devices. The company's expertise in precision mold making and their state-of-the-art facilities have earned them a stellar reputation among their clients.With an unwavering dedication to quality, Pla Plastic Molds has continuously invested in cutting-edge technology and equipment to ensure that they are at the forefront of the industry. Their team of highly skilled engineers and technicians are constantly pushing the boundaries of innovation, and are committed to delivering the best possible solutions for their clients' plastic molding needs.In addition to their commitment to excellence, Pla Plastic Molds is also dedicated to sustainability and environmental responsibility. The company has implemented eco-friendly practices in their manufacturing processes, and they prioritize the use of recyclable materials in their products. This commitment to environmentally-friendly practices has set them apart from many of their competitors and has helped them establish a strong presence in the market.Recently, Pla Plastic Molds has made headlines with the introduction of their latest line of plastic molds, which promise to revolutionize the industry. These new molds are designed to be more durable, precise, and efficient than ever before, and are expected to set a new standard for plastic mold manufacturing. The company's investment in research and development has paid off, and their new products have been met with enthusiasm and excitement from their clients and industry experts alike.One of the key factors behind the success of Pla Plastic Molds is their commitment to customer satisfaction. The company's dedicated team of professionals works closely with their clients to understand their specific needs and provide tailored solutions that meet and exceed their expectations. This customer-centric approach has earned them a loyal base of clients who trust them to deliver outstanding results consistently.Looking ahead, Pla Plastic Molds is poised for continued growth and success in the industry. With their relentless pursuit of innovation, unwavering commitment to quality, and dedication to customer satisfaction, the company is well-positioned to maintain its position as a leader in the plastic mold manufacturing industry.In conclusion, Pla Plastic Molds continues to make waves in the industry with their innovative products and unwavering commitment to excellence. With their dedication to quality, sustainability, and customer satisfaction, the company is setting a new standard for plastic mold manufacturing. As they continue to push the boundaries of innovation and expand their product line, Pla Plastic Molds is well-equipped to remain a key player in the industry for years to come.

Injection Molding: A Guide to IML Technology

Iml Injection Molding is a leading manufacturing process that has revolutionized the production of plastic parts. This innovative technology has allowed companies to produce high-quality, durable, and intricate plastic components with unparalleled precision and efficiency. With the use of advanced machinery, high-grade materials, and sophisticated software, Iml Injection Molding has become the preferred choice for many industries, including automotive, electronics, consumer goods, and medical devices. The process involves injecting molten plastic into a mold cavity, where it is shaped and cooled to form a finished product. The In-Mold Labeling (IML) technology further enhances the product by incorporating the label or decoration directly into the mold, resulting in a seamless and durable finish.The company {} has been at the forefront of this technological advancement, offering a wide range of Iml Injection Molding solutions to meet the diverse needs of its clients. With state-of-the-art facilities, a highly skilled workforce, and a commitment to excellence, {} has established itself as a reliable and innovative partner for businesses seeking top-notch plastic manufacturing services.{} specializes in custom mold design and fabrication, precision injection molding, and in-mold labeling for various industries. From automotive interior parts and electronic housings to food packaging and medical devices, {} has the expertise and capabilities to deliver complex and high-quality plastic components that meet the highest industry standards.One of the key advantages of Iml Injection Molding is its ability to produce parts with intricate designs and complex geometries. This is made possible through the use of specialized molds and advanced machinery that can achieve tight tolerances and superior surface finishes. As a result, products manufactured using Iml Injection Molding are not only visually appealing but also functionally superior, making them ideal for a wide range of applications.In addition to its technical capabilities, {} places a strong emphasis on sustainability and environmental responsibility. The company is committed to using recyclable materials, reducing waste, and optimizing energy consumption in its manufacturing processes. By adopting eco-friendly practices, {} not only contributes to a healthier planet but also helps its clients meet their sustainability goals.Moreover, {} is dedicated to continuous improvement and innovation. The company invests in research and development to stay ahead of the latest industry trends and technology advancements. By embracing new materials, processes, and design techniques, {} ensures that its clients receive cutting-edge solutions that give them a competitive edge in their respective markets.As a customer-centric company, {} prides itself on its ability to provide tailored solutions that meet the unique requirements of each client. By collaborating closely with its customers, {} gains a deep understanding of their needs and preferences, allowing the company to deliver personalized and cost-effective Iml Injection Molding solutions that exceed expectations.With a strong track record of delivering exceptional results, {} has earned the trust and loyalty of its clients, who rely on the company for their most demanding plastic manufacturing projects. By consistently delivering top-quality products, on-time delivery, and responsive customer service, {} has built a reputation as a partner that businesses can depend on for their Iml Injection Molding needs.In conclusion, Iml Injection Molding is a game-changer in the world of plastic manufacturing, and {} is at the forefront of this technological revolution. With its advanced capabilities, commitment to sustainability, and customer-centric approach, {} is well-positioned to continue leading the way in delivering high-quality and innovative Iml Injection Molding solutions. Businesses seeking a reliable and forward-thinking manufacturing partner need look no further than {}.

Cutting-Edge Prototype Designs: Tailored Solutions for Your Needs

Customized Prototype and (company name) Team Up to Advance Innovative Technology SolutionsIn a strategic collaboration, (company name) has partnered with Customized Prototype to accelerate the development of innovative technology solutions. Customized Prototype, a leading provider of customized prototyping services, brings its expertise in rapid prototyping and product development to the table, while (company name) will leverage its cutting-edge technology and industry knowledge to drive the collaboration forward.This partnership marks a significant milestone for both companies, as it combines Customized Prototype's proficiency in prototype manufacturing with (company name)'s prowess in advanced technology solutions. By joining forces, the two companies aim to deliver groundbreaking products and services that will revolutionize the industry.Customized Prototype is renowned for its unparalleled capabilities in producing customized prototypes for a wide range of industries, including automotive, aerospace, consumer electronics, and medical devices. With state-of-the-art manufacturing facilities and a team of experienced engineers, Customized Prototype has earned a reputation for delivering high-quality prototypes with exceptional precision and speed.On the other hand, (company name) is a trailblazer in the field of advanced technology solutions, specializing in cutting-edge developments such as artificial intelligence, internet of things, and virtual reality. With a strong focus on innovation and a commitment to pushing the boundaries of what is possible, (company name) is well-positioned to drive the collaboration with Customized Prototype to new heights."We are thrilled to partner with Customized Prototype," said a spokesperson from (company name). "Their expertise in rapid prototyping and product development is unparalleled, and we believe that by working together, we can achieve great success in bringing innovative technology solutions to the market."The partnership between Customized Prototype and (company name) is poised to have a significant impact on the industry, as it will allow for the seamless integration of advanced technology solutions into the prototyping process. By harnessing the power of cutting-edge technologies, the collaboration aims to streamline the product development cycle, reduce time-to-market, and ultimately deliver superior products that meet the evolving needs of customers.Moreover, the combined capabilities of Customized Prototype and (company name) will enable the development of customized prototypes that are tailored to the specific requirements of each industry. This will open up new possibilities for companies looking to bring innovative products to market, while also providing them with a competitive edge in their respective industries.In addition to driving innovation, the partnership between Customized Prototype and (company name) is expected to create new opportunities for collaboration and knowledge sharing. By working closely together, the two companies will be able to exchange valuable insights and best practices, ultimately leading to the development of more effective and efficient prototyping solutions.As the collaboration between Customized Prototype and (company name) gathers momentum, both companies are optimistic about the potential impact it will have on the industry. By combining their strengths and expertise, they aim to set new standards for rapid prototyping and product development, and pave the way for a future where innovative technology solutions are seamlessly integrated into every stage of the manufacturing process.With the backing of Customized Prototype's advanced prototyping capabilities and (company name)'s cutting-edge technology solutions, the partnership is set to drive innovation and propel the industry into a new era of possibilities. As they embark on this transformative journey together, Customized Prototype and (company name) are poised to shape the future of technology and manufacturing, and usher in a new wave of innovative products and services for the world.

Ultimate Guide to Machining Prototyping: Tips and Techniques for Rapid Prototyping

Machining Prototyping has become an essential part of the manufacturing process for numerous industries around the world. From aerospace to automotive, medical to consumer goods, the need for precision prototyping and machining services has never been greater. One company at the forefront of this industry is {}.{} is a leading provider of machining prototyping services, offering a wide range of capabilities to meet the specific needs of their clients. With a strong emphasis on quality, efficiency, and customer satisfaction, {} has established itself as a premier partner for businesses looking to bring their designs to life.One of the key factors that sets {} apart from their competitors is their commitment to utilizing the latest technology and cutting-edge equipment. This allows them to deliver superior results with a high degree of accuracy and consistency. From CNC machining to 3D printing, {} has the capabilities to handle a wide variety of prototyping and production needs.In addition to their state-of-the-art equipment, {} also prides itself on its highly skilled and experienced team of engineers and technicians. This team is dedicated to working closely with clients to understand their unique requirements and deliver tailored solutions that meet or exceed their expectations. Whether it's a complex aerospace component or a prototype for a new medical device, {} has the expertise and resources to deliver results.Furthermore, {} is committed to maintaining the highest standards of quality and reliability in all of their processes. This includes rigorous quality control measures and adherence to industry best practices. As a result, clients can trust that their prototyping and machining needs are in capable hands when they partner with {}.Another area where {} excels is in their ability to provide quick turnaround times without compromising on quality. In today's fast-paced business environment, speed to market is often critical, and {} understands this. They strive to work efficiently and effectively to deliver prototypes and machined parts in a timely manner, helping clients stay ahead of their competition.Moreover, {} is constantly investing in research and development to stay ahead of the curve and stay up to date with the latest advancements in prototyping and machining technology. This forward-thinking approach ensures that they remain a leader in the industry and can continue to provide innovative solutions for their clients' evolving needs.As a testament to their commitment to excellence, {} has built a strong reputation within the manufacturing and prototyping industry. They have earned the trust and respect of clients across various sectors who rely on their expertise and capabilities to bring their designs to life. Whether it's a small start-up or a large multinational corporation, {} has the flexibility to accommodate their needs and deliver outstanding results.In conclusion, {} is a trusted and respected provider of machining prototyping services, known for their cutting-edge technology, skilled team, and dedication to quality and customer satisfaction. With a focus on innovation and efficiency, {} continues to be a valuable partner for businesses looking to turn their ideas into reality. For any company seeking reliable and high-quality prototyping and machining services, {} is the name to remember.

Advanced 4 Axis Machining: What You Need to Know

5-Axis Machining Technology Taking Precision Manufacturing to the Next LevelIn today's rapidly evolving world, precision manufacturing is more important than ever. As industries continue to push the boundaries of what can be achieved, the need for ultra-precise machining capabilities has never been greater. This is where 5-axis machining comes into play. The technology behind 5-axis machining is revolutionizing the way precision manufacturing is done, allowing for intricate, complex parts to be produced with unprecedented accuracy.The concept of 5-axis machining is relatively simple to understand. Traditional machining operates on three axes—X, Y, and Z—allowing for movement in three directions. 5-axis machining, as the name suggests, adds two additional axes of movement, typically allowing for rotation around the X and Y axes. This added flexibility allows for much greater freedom in the types of parts that can be produced, as well as the precision with which they can be manufactured.One company at the forefront of this cutting-edge technology is {}. With a proven track record of delivering high-quality precision components to a wide range of industries, their investment in 5-axis machining technology is a natural progression in their commitment to staying ahead of the curve.{} is a leading provider of precision machining services, offering a comprehensive range of capabilities to meet the needs of their diverse customer base. From aerospace and defense to medical and automotive, {} has built a reputation for delivering exceptional quality and precision in every part they produce.By embracing 5-axis machining technology, {} is taking their precision manufacturing capabilities to the next level. With the ability to perform complex, multi-sided machining operations in a single setup, 5-axis machining allows {} to produce parts with a level of precision and intricacy that was previously unattainable. This not only enhances the quality of their products but also increases efficiency and reduces lead times, allowing them to better meet the needs of their customers.The benefits of 5-axis machining are not limited to the manufacturing process itself. The increased capabilities offered by this technology open up a world of possibilities for design engineers. With the ability to produce parts with more intricate geometries and complex features, designers are no longer constrained by the limitations of traditional machining methods. This allows for greater innovation and creativity in product development, ultimately resulting in parts and products that are not only more precise but also more functional and efficient.The impact of 5-axis machining is far-reaching, with implications for a wide range of industries. In aerospace and defense, where precision and reliability are paramount, the ability to produce complex components with unmatched accuracy is crucial. In the medical industry, where the demand for miniaturized, intricately designed devices is on the rise, 5-axis machining opens up new possibilities for innovation. And in the automotive sector, where lightweight, high-strength components are increasingly in demand, the precision and flexibility of 5-axis machining are invaluable.As the world continues to evolve, so too must the technologies that drive it forward. With its ability to deliver unparalleled precision and complexity, 5-axis machining is poised to play a crucial role in the future of precision manufacturing. Companies like {} are at the forefront of this revolution, embracing the latest technologies to push the boundaries of what's possible and deliver the high-quality, precise components that the modern world demands.

The Benefits of Thermoplastic Injection Molding

Thermoplastic injection is a versatile process used in the manufacturing industry to produce a wide range of products. It involves injecting molten thermoplastic material into a mold, which then hardens to form the desired shape. This process is used to create a variety of products, including automotive parts, electronic components, medical devices, and consumer goods.One company that has made a name for itself in the field of thermoplastic injection is {}, a leading provider of injection molded plastic parts and components. With a strong focus on innovation and quality, {} has established itself as a trusted partner for companies looking to bring their ideas to life through injection molding.Founded in {}, {} has over {} years of experience in the industry and has continued to evolve and grow with the changing demands of the market. The company's state-of-the-art facilities are equipped with the latest injection molding technology, allowing them to produce high-quality plastic parts with precision and efficiency.{}'s team of experienced engineers and technicians work closely with clients to understand their specific requirements and provide customized solutions to meet their needs. Whether it's a small-scale production run or a large-scale project, {} has the capabilities to deliver on time and within budget.One of the key advantages of thermoplastic injection is its ability to produce complex shapes and intricate designs with high precision. This makes it an ideal manufacturing process for companies looking to create custom components for their products. With {}'s expertise in thermoplastic injection, clients can be assured that their designs will be realized with the highest degree of accuracy and quality.In addition to their injection molding capabilities, {} also offers a range of value-added services, including product design and development, prototyping, and post-molding assembly. This comprehensive approach allows clients to streamline their production process and reduce costs while maintaining high standards of quality.With a strong commitment to sustainability, {} also prioritizes environmental responsibility in their manufacturing processes. They have implemented various eco-friendly initiatives, such as using recycled materials and optimizing energy efficiency in their operations. This not only benefits the environment but also helps clients meet their own sustainability goals.The company's dedication to excellence has earned them a strong reputation in the industry, with a track record of delivering innovative solutions and exceeding customer expectations. Their focus on continuous improvement and investment in advanced technology ensures that they remain at the forefront of thermoplastic injection molding.Looking ahead, {} is poised to continue their growth and expansion, with plans to further enhance their capabilities and offerings in thermoplastic injection. They aim to strengthen their partnerships with clients and remain a trusted provider of high-quality plastic components for a wide range of industries.In conclusion, thermoplastic injection is a critical process in the manufacturing industry, and {} is a leading player in this field. With their expertise, innovation, and commitment to quality, they have established themselves as a go-to partner for companies seeking top-notch injection molded plastic parts and components. As they continue to evolve and grow, {} is well-positioned to meet the diverse needs of their clients and drive the industry forward.

High-Quality Rubber Parts for Various Uses: A Comprehensive Overview

Rubber Parts is a leading supplier of high-quality rubber components for a variety of industries, including automotive, aerospace, electronics, and more. With a focus on innovation and quality, Rubber Parts has established itself as a trusted partner for companies looking for reliable and durable rubber solutions.The company offers a wide range of rubber parts, including seals, gaskets, O-rings, and custom-molded components. These parts are designed to meet the specific needs of each customer, providing a perfect fit and long-lasting performance.Rubber Parts has a state-of-the-art manufacturing facility, where they utilize the latest technology and machinery to produce high-quality rubber parts. Each part is carefully crafted and inspected to ensure it meets the strict quality standards set by the company.In addition to their standard product offerings, Rubber Parts also has the capabilities to create custom solutions for unique applications. Their team of experienced engineers and technicians work closely with customers to develop customized rubber parts that meet their exact specifications.One of the key strengths of Rubber Parts is their commitment to continuous improvement and innovation. The company invests heavily in research and development, constantly seeking new materials and processes to improve the performance and durability of their rubber parts.Rubber Parts also places a strong emphasis on sustainability and environmental responsibility. They strive to minimize waste and energy consumption in their manufacturing processes, and are constantly exploring new ways to reduce their environmental impact.The company is also dedicated to providing exceptional customer service. Their team of experts are always available to provide technical support, answer questions, and help customers find the right rubber parts for their needs.With a reputation for reliability, quality, and innovation, Rubber Parts has established itself as a trusted partner for companies around the world. Their commitment to excellence and customer satisfaction has made them a leader in the rubber parts industry.In recent news, Rubber Parts has announced the launch of a new line of eco-friendly rubber parts, designed to provide the same high-quality performance while reducing the company's environmental impact. These new parts are made from sustainable materials and are produced using environmentally friendly processes, showcasing the company's dedication to sustainability and innovation."We are constantly looking for ways to improve our products and processes, while also minimizing our environmental impact," said a spokesperson for Rubber Parts. "Our new eco-friendly rubber parts are just another example of our commitment to sustainability and innovation."The company is confident that these new eco-friendly rubber parts will be well-received by their customers, as they continue to provide reliable and durable solutions for a wide range of industries.As Rubber Parts continues to expand its product offerings and explore new opportunities for growth, the company remains dedicated to its core values of quality, innovation, and customer satisfaction. With a focus on sustainability and a commitment to excellence, Rubber Parts is poised to continue its success as a leader in the rubber parts industry.In conclusion, Rubber Parts is a company that is dedicated to providing high-quality, reliable rubber parts for a variety of industries. With a focus on innovation, sustainability, and customer satisfaction, it is clear that the company will continue to thrive and remain a trusted partner for companies seeking durable rubber solutions.

Understanding the Process of Injection Molding

Injection molding is a manufacturing process for producing parts by injecting material into a mold. It is commonly used for creating a wide range of products, from plastic toys to automotive parts. With the advancement of technology, injection molding has become more efficient and cost-effective, allowing companies to produce high-quality parts in large quantities.One company that has embraced the use of injection molding is {}. They have established themselves as a leading manufacturer in the industry, utilizing state-of-the-art injection molding machines to meet the demands of their clients. The company has a team of experienced engineers and technicians who are dedicated to delivering top-notch products to their customers.One of the key benefits of injection molding is its ability to produce complex shapes with high precision. This is achieved by designing a custom mold that is filled with the material and then cooled to solidify the part. {}. has invested in advanced mold-making technology to ensure that their products meet the highest standards of quality and accuracy.In addition to precision, injection molding offers fast production speeds, making it an ideal choice for companies looking to mass-produce their products. {}. has multiple injection molding machines, allowing them to fulfill both small and large orders in a timely manner. This has enabled the company to build a reputation for delivering products on time, without compromising on quality.Furthermore, injection molding allows for the use of a wide range of materials, including thermoplastics, metals, and elastomers. This versatility gives companies the flexibility to choose the best material for their specific application. {}. has expertise in working with various materials, ensuring that they can meet the diverse needs of their clients.Another advantage of injection molding is its cost-effectiveness. The process is highly automated, reducing the need for manual labor and minimizing the risk of errors. This helps companies like {} to keep production costs low, making their products more competitive in the market.Moreover, injection molding is an environmentally friendly manufacturing process. It generates minimal waste and allows for the recycling of excess material. As a responsible manufacturer, {}. has implemented sustainable practices in their production process, minimizing their environmental impact.In recent years, the demand for injection-molded products has been on the rise, driven by the growing automotive, consumer goods, and medical industries. {}. has positioned itself as a reliable partner for companies looking to take advantage of the benefits of injection molding. Their commitment to quality, efficiency, and customer satisfaction has earned them a loyal client base and has fueled their growth in the industry.Looking ahead, the company is focused on continuous improvement and innovation. They are exploring new materials and technologies to expand their capabilities and offer even better solutions to their clients. With a strong foundation in injection molding and a dedication to excellence, {}. is well-positioned to remain a leader in the industry for years to come.In conclusion, injection molding is a vital manufacturing process that has revolutionized the production of a wide range of products. {}. has demonstrated a strong commitment to excellence in injection molding, utilizing advanced technology and expertise to deliver high-quality products to their clients. With their focus on precision, efficiency, and innovation, the company is well-equipped to meet the evolving needs of the market and maintain its position as a trusted partner for manufacturing solutions.

Exploring the Benefits of Rapid Prototyping in Product Development

Rapid Prototype Revolutionizing Manufacturing ProcessesIn today's fast-paced world, the demand for speedy and efficient manufacturing processes is at an all-time high. This is where Rapid Prototype comes into play, offering innovative solutions that are revolutionizing the way companies design and develop products.Rapid Prototype specializes in providing cutting-edge prototyping services to a wide range of industries, including automotive, aerospace, medical, and consumer goods. With a team of experienced engineers and state-of-the-art technology, Rapid Prototype has earned a reputation for delivering high-quality prototypes in record time.One of the key factors that sets Rapid Prototype apart is its commitment to using the latest 3D printing technology. This allows the company to create prototypes with incredible precision and detail, giving clients a realistic representation of their final product. By leveraging 3D printing, Rapid Prototype is able to drastically reduce the time and cost associated with traditional prototyping methods, providing clients with a competitive edge in their respective industries.Furthermore, Rapid Prototype offers a wide range of materials for prototyping, including plastics, metals, and composites, ensuring that their clients can test and evaluate different designs and materials before committing to mass production. This flexibility is crucial in helping companies refine their products and ensure that they meet the highest standards of quality and performance.In addition to its prototyping services, Rapid Prototype also offers design and engineering support to help clients bring their ideas to life. The company's team of experts works closely with clients to understand their requirements and provide valuable insights and recommendations throughout the prototyping process. This collaborative approach has allowed Rapid Prototype to build long-lasting partnerships with leading companies in various industries.One such success story involves a leading automotive manufacturer that turned to Rapid Prototype for assistance in developing a new car part. The manufacturer was facing significant challenges in prototyping the complex component, and Rapid Prototype was able to deliver a fully functional prototype within a matter of days. This accelerated timeline allowed the manufacturer to test the part in real-world conditions and make necessary design adjustments before moving into mass production, ultimately saving them time and money.Rapid Prototype's commitment to innovation and customer satisfaction has led to its rapid growth and expansion in recent years. The company has continued to invest in the latest technologies and equipment to further improve its prototyping capabilities, ensuring that its clients have access to the best resources available.Looking ahead, Rapid Prototype is poised to continue its trajectory of success, with plans to further expand its services and reach new markets. The company's dedication to pushing the boundaries of prototyping and manufacturing is not only benefiting its clients, but also contributing to the overall advancement of the industry.In conclusion, Rapid Prototype's commitment to excellence and innovation has cemented its position as a leader in the prototyping industry. By leveraging cutting-edge 3D printing technology, offering a diverse range of materials, and providing expert engineering support, Rapid Prototype is empowering companies to bring their ideas to life with unprecedented speed and efficiency. As the demand for rapid prototyping continues to grow, Rapid Prototype is well-positioned to remain at the forefront of this transformative industry.