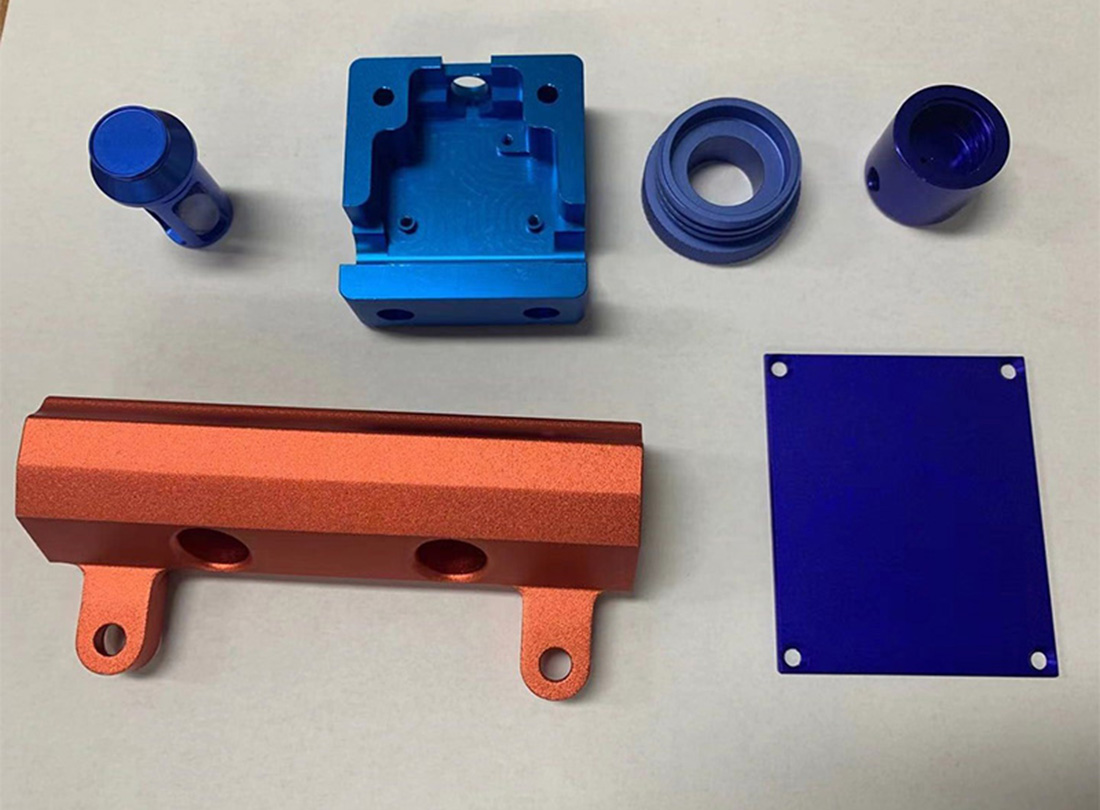

High-quality Precision Brass Parts Welding and Bending Services Available

By:Admin

The company has been in the precision manufacturing industry for over 20 years, specializing in the production of high-quality brass parts for various industries including automotive, aerospace, electronics, and medical. With a commitment to excellence and continuous improvement, Precision Manufacturing Company has earned a reputation for delivering exceptional products and services to its clients.

In response to the increasing demand for precision brass parts welding and bending services, the company has invested in state-of-the-art equipment and technology to enhance its manufacturing capabilities. This investment has enabled Precision Manufacturing Company to offer a wider range of services to its customers, including precision TIG welding, robotic welding, and CNC bending.

The expansion of the company's capabilities is in line with its dedication to providing comprehensive solutions to its customers' manufacturing needs. By offering precision brass parts welding and bending services, Precision Manufacturing Company aims to become a one-stop shop for all precision manufacturing requirements, from design and prototyping to production and assembly.

"We are excited to announce the expansion of our capabilities to include precision brass parts welding and bending services," said the CEO of Precision Manufacturing Company. "This expansion is a testament to our commitment to meeting the evolving needs of our customers and providing them with the highest quality products and services."

With the addition of precision brass parts welding and bending services, Precision Manufacturing Company can now offer a complete range of manufacturing solutions to its customers. Whether they require small or large volume production, complex or simple parts, the company's expanded capabilities allow it to meet a wide variety of requirements with precision and efficiency.

The company's team of highly skilled engineers and technicians are equipped with the expertise and experience to handle the most challenging welding and bending projects. Whether it's creating intricate bends in brass tubing or welding complex assemblies, Precision Manufacturing Company can deliver precise and reliable results that meet the highest standards of quality and craftsmanship.

In addition to its expanded capabilities, Precision Manufacturing Company remains committed to upholding the highest standards of quality and safety in its manufacturing processes. The company follows strict quality control measures to ensure that every part produced meets the exact specifications and requirements of its customers. Furthermore, it complies with industry regulations and standards to ensure the safety and integrity of its products.

The expansion of Precision Manufacturing Company's capabilities comes as a response to the growing demand for precision manufacturing services in the industry. By offering a comprehensive range of services, the company aims to strengthen its position as a trusted partner for its customers, providing them with the expertise, resources, and support they need to bring their products to market.

As the company continues to grow and expand its capabilities, it remains committed to its core values of innovation, quality, and customer satisfaction. Precision Manufacturing Company sees its expansion as a step forward in its journey to becoming a global leader in precision manufacturing, providing reliable and comprehensive solutions to its customers' most demanding requirements.

With its expanded capabilities in precision brass parts welding and bending services, Precision Manufacturing Company is poised to meet the evolving needs of its customers and continue its legacy of excellence in the precision manufacturing industry.

Company News & Blog

Complete Guide to Elastomer Injection Molding Process

Elastomer Injection Molding (EIM) has quickly become the go-to solution for many industries seeking precise and efficient manufacturing of elastomer products. With its ability to produce high-quality, complex parts with consistent results, EIM has revolutionized the way elastomers are utilized in a wide range of applications. One company that has been at the forefront of this innovation is {Company}, a leading provider of elastomer injection molding solutions.Established in {year}, {Company} has amassed a wealth of experience and expertise in the elastomer injection molding industry. With a strong focus on research and development, the company has continually pushed the boundaries of what is possible with elastomers, developing cutting-edge processes and technologies to meet the evolving needs of its customers.The key to {Company}'s success lies in its state-of-the-art facilities and equipment. The company boasts a modern production facility that is equipped with the latest elastomer injection molding machines, allowing for the precise and efficient manufacturing of a wide variety of elastomer products. Additionally, {Company} has a team of highly skilled and experienced engineers who work closely with customers to develop custom molding solutions that meet their specific requirements.One of the main advantages of EIM is its ability to produce parts with exceptional precision and consistency. This is due to the advanced control systems and technology utilized in the molding process, ensuring that each part meets the exacting standards set by customers. {Company} has leveraged this capability to deliver high-quality elastomer products to industries such as automotive, medical, aerospace, and consumer goods.In the automotive industry, for example, {Company} has been a key supplier of elastomer components for various applications, including sealing systems, vibration isolators, and gaskets. By utilizing EIM, the company has been able to produce these parts with tight tolerances and excellent durability, meeting the stringent requirements of the automotive sector.In the medical industry, {Company} has played a crucial role in the production of elastomer components for medical devices and equipment. The company's ability to consistently manufacture parts that meet the strict regulatory standards of the medical industry has made it a trusted partner for medical device manufacturers worldwide.{Company} has also made significant strides in the aerospace industry, providing elastomer components for critical applications such as aircraft seals, O-rings, and vibration dampeners. The company's expertise in EIM has allowed it to produce parts that are not only lightweight and durable but also capable of withstanding the extreme conditions of aerospace environments.Furthermore, {Company} has been working closely with customers in the consumer goods industry to develop custom elastomer solutions for a wide range of products, including electronic devices, appliances, and sporting goods. By harnessing the capabilities of EIM, the company has been able to offer innovative and high-performance elastomer products that meet the unique requirements of consumer goods manufacturers.Looking ahead, {Company} remains committed to driving innovation in the elastomer injection molding industry. With a focus on continuous improvement and staying ahead of the curve, the company is poised to meet the evolving needs of its customers and provide cutting-edge solutions for a wide range of applications.As the demand for high-quality elastomer products continues to grow across industries, {Company} stands ready to lead the way with its advanced elastomer injection molding capabilities. With a strong track record of delivering precision, consistency, and innovation, the company is well-positioned to shape the future of elastomer manufacturing and meet the diverse needs of its customers.

Best Tips for Mold Plastic Injection

Mold Plastic Injection, a leading manufacturer in the plastic injection molding industry, has recently made significant advancements in their production capabilities, allowing them to provide customers with even higher quality products. With a focus on innovation and cutting-edge technology, Mold Plastic Injection has positioned itself as a key player in the market.Established in [year], Mold Plastic Injection has consistently demonstrated a commitment to excellence in plastic injection molding. The company takes pride in its state-of-the-art facilities, which are equipped with the latest machinery and technology to ensure precision and efficiency in the manufacturing process. With a team of highly skilled engineers and technicians, Mold Plastic Injection has the expertise to deliver custom solutions to meet the unique needs of its clients.One of the key factors that sets Mold Plastic Injection apart from its competitors is its dedication to continuous improvement. The company regularly invests in research and development to explore new materials and techniques that can enhance the quality and performance of its products. As a result, Mold Plastic Injection is able to offer a wide range of plastic injection molding solutions, including custom molding, insert molding, overmolding, and more.In line with its commitment to innovation, Mold Plastic Injection has recently introduced a new production process that has significantly improved the quality of its plastic injection molded products. By incorporating advanced molding techniques and materials, the company has been able to achieve greater precision and consistency in its output. This has not only led to higher quality products, but also increased efficiency in the production process, allowing Mold Plastic Injection to meet the growing demands of its customers.Furthermore, Mold Plastic Injection has also expanded its capabilities to accommodate larger and more complex projects. The company has invested in new machinery and equipment that enable it to handle a wider range of mold sizes and designs, giving customers the flexibility to realize their unique visions. This expansion has positioned Mold Plastic Injection as a versatile and reliable partner for clients in various industries, including automotive, medical, consumer goods, and more.In addition to its technical capabilities, Mold Plastic Injection is also committed to upholding the highest standards of quality and safety. The company adheres to strict quality control measures throughout the production process, ensuring that every product that leaves its facilities meets the most rigorous standards. Mold Plastic Injection also places a strong emphasis on sustainability, utilizing eco-friendly materials and processes to minimize its environmental impact.As Mold Plastic Injection continues to push the boundaries of plastic injection molding, the company remains dedicated to providing exceptional customer service. With a focus on collaboration and communication, Mold Plastic Injection works closely with its clients to understand their needs and deliver tailored solutions that exceed expectations. This customer-centric approach has earned Mold Plastic Injection a reputation for reliability and integrity in the industry.Looking ahead, Mold Plastic Injection is poised for continued growth and success in the plastic injection molding market. With its commitment to innovation, quality, and customer satisfaction, the company is well-positioned to meet the evolving needs of its clients and maintain its leadership in the industry. Mold Plastic Injection's dedication to excellence and continuous improvement sets it apart as a trusted partner for all plastic injection molding needs.

High-Quality Precision Injection Molds for Various Industries

Precision Injection Molds, a leading manufacturer of high-quality injection molds, has established itself as a key player in the industry. With their dedication to innovation, quality, and customer satisfaction, Precision Injection Molds has earned a reputation as a reliable and trusted partner for companies in various sectors, including automotive, medical, consumer goods, and more.Established in [year], Precision Injection Molds has quickly risen to prominence in the industry due to its commitment to delivering superior products and exceptional service. The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing them to produce molds with unmatched precision and consistency. Additionally, their team of highly skilled engineers and technicians are constantly pushing the boundaries of innovation to develop cutting-edge solutions for their clients.Precision Injection Molds specializes in the design and manufacturing of complex, high-precision injection molds. Their molds are used for a wide range of applications, including automotive components, medical devices, consumer electronics, and more. The company's expertise in this area has made them a preferred supplier for many leading companies, who rely on Precision Injection Molds to deliver molds that meet their exact specifications and requirements.One of the key factors that sets Precision Injection Molds apart from their competitors is their commitment to quality. The company uses only the finest materials and manufacturing processes to ensure that their molds meet the highest standards of quality and durability. Additionally, their rigorous quality control procedures and testing protocols guarantee that every mold that leaves their facility is free from defects and meets the strictest industry standards.In addition to their focus on quality, Precision Injection Molds also places a strong emphasis on customer satisfaction. The company works closely with each client to fully understand their unique needs and challenges, allowing them to develop custom solutions that are tailored to meet those specific requirements. Whether it's a complex mold design or a tight production timeline, Precision Injection Molds has the expertise and resources to deliver results that exceed expectations.Furthermore, Precision Injection Molds prides itself on its ability to stay ahead of the curve when it comes to technological advancements in the industry. The company is constantly investing in research and development to explore new materials, processes, and techniques that can enhance the performance and efficiency of their molds. This forward-thinking approach has allowed Precision Injection Molds to stay at the forefront of the industry and continue to offer innovative solutions to their clients.With their unwavering commitment to excellence, Precision Injection Molds has built a solid reputation as a premier provider of high-quality injection molds. Their dedication to quality, innovation, and customer satisfaction has earned them the trust and loyalty of companies across various industries. As they continue to expand their capabilities and push the boundaries of what's possible in injection mold manufacturing, Precision Injection Molds is poised to remain a key player in the industry for years to come.

High-Quality Component Machining for Precision Engineering needs

Precise Component Machining, a leading precision engineering company, is known for its high-quality components and expertise in machining a wide range of materials. The company has built a reputation for delivering precision parts to the aerospace, automotive, medical, and electronics industries. With state-of-the-art technology and a skilled workforce, Precise Component Machining has positioned itself as a key player in the manufacturing sector.Founded in 1990, Precise Component Machining has continuously invested in the latest machining equipment and technologies to meet the evolving demands of its customers. The company's commitment to quality and innovation has allowed it to stay ahead of the competition and maintain long-term relationships with its clients.Precise Component Machining specializes in CNC milling, CNC turning, and Swiss machining, offering a comprehensive range of services to meet the specific needs of its customers. The company's capabilities include the machining of complex shapes and features, tight tolerances, and intricate designs. This level of precision and attention to detail has made Precise Component Machining a preferred partner for companies seeking high-quality components for their products.In addition to its machining capabilities, Precise Component Machining also provides value-added services such as assembly, finishing, and inspection. The company's comprehensive approach to manufacturing ensures that its customers receive fully finished components that meet their exact specifications.One of the key factors that sets Precise Component Machining apart from its competitors is its commitment to continuous improvement. The company regularly invests in training and development programs for its employees to ensure that they are equipped with the skills and knowledge needed to deliver top-notch products. Additionally, Precise Component Machining actively seeks feedback from its customers to identify areas for improvement and to better understand their evolving needs.In recent news, Precise Component Machining has announced the acquisition of a new 5-axis CNC milling machine. This investment will further enhance the company's capabilities and allow it to take on more complex projects with increased efficiency and accuracy. The new machine is equipped with advanced features that will enable Precise Component Machining to produce even tighter tolerances and more intricate designs, solidifying its position as a leader in precision machining."We are thrilled to add this state-of-the-art CNC milling machine to our equipment lineup," said the CEO of Precise Component Machining. "This investment demonstrates our commitment to staying at the forefront of machining technology and providing our customers with the highest quality components."The addition of the new CNC milling machine is just one example of Precise Component Machining's dedication to staying ahead of the curve. The company continues to explore new opportunities for growth and improvement, with a focus on expanding its capabilities and serving a wider range of industries."We are always looking for ways to better serve our customers and meet their ever-changing needs," the CEO continued. "Whether it's investing in new equipment, expanding our expertise, or enhancing our processes, we are committed to providing exceptional products and service."In conclusion, Precise Component Machining is a dynamic and forward-thinking company that is well-positioned to continue its success in the precision engineering industry. With a strong focus on quality, innovation, and customer satisfaction, the company is poised to meet the evolving demands of its customers and maintain its reputation as a leader in precision machining. The acquisition of the new 5-axis CNC milling machine is a testament to Precise Component Machining's commitment to excellence and its determination to remain at the forefront of the industry.

High-Quality CNC Turned Components for Your Manufacturing Needs

CNC turned components are a crucial part of modern manufacturing processes. These components are used in a wide range of industries, including automotive, aerospace, electronics, and medical device manufacturing. The precision and high quality of CNC turned components make them popular in the production of complex and intricate parts.With the advancement of technology, the demand for high-quality CNC turned components has been increasing. As a result, many manufacturers are now turning to CNC machining to produce these components. One such company that has been leading the way in the manufacturing of CNC turned components is {}.{} is a leading manufacturer of CNC turned components, specializing in producing high precision parts for a variety of industries. With state-of-the-art facilities and a team of skilled engineers and technicians, {} has positioned itself as a industry leader in the production of CNC turned components.The company has a wide range of CNC machining capabilities, including turning, milling, drilling, and grinding. This allows them to produce components with tight tolerances and complex geometries, meeting the high standards required by their customers.In addition to their advanced machining capabilities, {} also focuses on quality control and inspection processes to ensure that every component they produce meets the highest standards. This commitment to quality has earned {} a reputation for delivering precision components that meet and exceed the expectations of their customers.One of the key advantages of CNC turned components is their ability to be produced in large quantities with consistent quality. This makes them an ideal choice for manufacturers who require high volume production of intricate parts. {} has the capacity to handle large production runs, making them a preferred supplier for many companies in need of CNC turned components.As the demand for precision components continues to grow, {} is continuously investing in the latest CNC machining technology to stay ahead of the competition. By staying at the forefront of innovation, {} is able to offer their customers the highest quality CNC turned components with shorter lead times and competitive pricing.In addition to their commitment to quality and innovation, {} prides itself on providing exceptional customer service. Their team of experts works closely with their clients to understand their specific needs and provide tailored solutions to meet those requirements. This personalized approach has helped {} build strong, long-term relationships with their customers, making them a trusted partner in the manufacturing industry.With their dedication to quality, innovation, and customer satisfaction, {} continues to be a leading force in the production of CNC turned components. As the demand for precision parts continues to rise, {} is well-equipped to meet the needs of the industry and deliver top-notch components to their customers.In conclusion, CNC turned components play a critical role in modern manufacturing processes, and {} has established itself as a leader in producing high-quality, precision components for a wide range of industries. With their advanced machining capabilities, commitment to quality, and exceptional customer service, {} is well-positioned to meet and exceed the demands of the evolving manufacturing landscape.

Sheet Metal Punch Processing: Aluminum Fabrication Techniques

Aluminum Sheet Metal Punch Processing Fabrication{Company Name} is proud to announce the launch of their new aluminum sheet metal punch processing fabrication service, which is designed to meet the growing demand for high-quality sheet metal fabrication in the industry.With the increasing need for lightweight and durable materials, aluminum has become a popular choice for a wide range of applications, from automotive and aerospace to construction and consumer electronics. {Company Name} recognizes this trend and has invested in state-of-the-art equipment and technology to offer a comprehensive aluminum sheet metal punch processing fabrication solution to their clients.The process of punch processing fabrication involves shaping and forming aluminum sheets into various components and parts for specific applications. This includes cutting, bending, punching, and assembling the sheets to create precise and intricate designs. {Company Name} has the capability to handle a wide range of sheet metal thicknesses and sizes, and their experienced team of engineers and technicians possesses the expertise to ensure the highest level of accuracy and quality in the fabrication process.In addition to offering superior quality, {Company Name} takes pride in their commitment to sustainability and environmental responsibility. Their aluminum sheet metal punch processing fabrication service is designed to minimize waste and reduce energy consumption, while also ensuring that the finished products meet the strictest environmental standards. This approach not only benefits their clients but also contributes to a more sustainable and eco-friendly manufacturing process.{Company Name} has established itself as a leading provider of sheet metal fabrication solutions, serving clients in various industries around the world. Their reputation for excellence and reliability is built on a strong foundation of innovation and customer satisfaction. By adding aluminum sheet metal punch processing fabrication to their portfolio, {Company Name} is further solidifying their position as a trusted partner for all sheet metal fabrication needs.The launch of this new service comes at a time when the demand for aluminum sheet metal fabrication is on the rise, driven by the growing need for lightweight and durable materials in various industries. {Company Name} is well-equipped to address this demand and deliver high-quality aluminum sheet metal punch processing fabrication that meets the unique requirements of their clients.With their extensive experience and comprehensive capabilities, {Company Name} is poised to make a significant impact in the aluminum sheet metal fabrication market. From custom components to large-scale production runs, their new service is designed to accommodate a wide range of needs and specifications, ensuring that their clients receive the best possible solution for their sheet metal fabrication requirements.In summary, {Company Name}'s new aluminum sheet metal punch processing fabrication service is a testament to their ongoing commitment to innovation, sustainability, and customer satisfaction. With their advanced technology, skilled workforce, and dedication to excellence, {Company Name} is well-positioned to serve as a premier provider of aluminum sheet metal fabrication solutions for the foreseeable future.For more information about {Company Name} and their aluminum sheet metal punch processing fabrication service, please visit their website or contact them directly for a personalized consultation.

High-Quality Plastic Mold Parts for Various Applications

Plastic Mold Parts is a renowned company in the manufacturing industry, specializing in high-quality plastic mold parts for various industries. With a strong commitment to innovation and customer satisfaction, Plastic Mold Parts has been a leading supplier of precision plastic components for many years.The company utilizes state-of-the-art manufacturing processes and advanced technologies to produce plastic mold parts that meet the highest industry standards. With a focus on precision and quality, Plastic Mold Parts has earned a reputation for excellence in the industry.One of the key factors that sets Plastic Mold Parts apart from its competitors is its dedication to customer service. The company prides itself on providing exceptional support and guidance to its clients throughout the entire production process. From the initial design phase to the final delivery of the products, Plastic Mold Parts works closely with its customers to ensure that their specific needs and requirements are met.In addition to its commitment to superior quality and customer service, Plastic Mold Parts also places a strong emphasis on environmental sustainability. The company is dedicated to minimizing its environmental impact and has implemented various measures to reduce waste and conserve resources in its manufacturing processes. By utilizing eco-friendly materials and implementing energy-efficient practices, Plastic Mold Parts is able to deliver high-quality products while minimizing its carbon footprint.Plastic Mold Parts serves a wide range of industries, including automotive, electronics, medical, and consumer goods. The company's extensive product line includes injection molded parts, insert molded parts, overmolded parts, and custom mold components. With a focus on versatility and flexibility, Plastic Mold Parts has the capability to produce a diverse range of plastic mold parts to meet the unique needs of its clients.In recent news, Plastic Mold Parts has announced the launch of a new line of innovative plastic mold parts that are designed to enhance performance and durability. These new products have been developed in response to the evolving needs of the market and are poised to set new industry standards for quality and reliability."We are thrilled to introduce our latest line of plastic mold parts to the market," said a spokesperson for Plastic Mold Parts. "These new products represent the culmination of extensive research and development, and we are confident that they will provide our customers with exceptional value and performance."Plastic Mold Parts is committed to staying at the forefront of the industry by continually investing in research and development to bring cutting-edge solutions to its clients. The company's team of skilled engineers and technicians are dedicated to pushing the boundaries of what is possible in plastic mold part manufacturing, with a focus on innovation and excellence.As the demand for high-quality plastic mold parts continues to grow across various industries, Plastic Mold Parts remains steadfast in its commitment to delivering top-tier products and services to its clients. With a strong foundation built on quality, precision, and customer satisfaction, Plastic Mold Parts is poised to maintain its position as a leading provider of plastic mold parts for years to come.

Creating Functional Prototypes: A Crucial Step in Product Development

Functional Prototypes Making Headway in Manufacturing Industry The manufacturing industry is constantly evolving with new technologies and innovations. One of the latest advancements in this field is the use of functional prototypes, which have the potential to revolutionize the way products are designed and developed. These prototypes are not just simple mock-ups, but fully functional models that closely mimic the final product. One company at the forefront of this trend is [Company name], a leading provider of advanced manufacturing solutions. The company has been at the forefront of creating functional prototypes that have already had a significant impact on the manufacturing industry. Their technology has been used by a wide range of industries, from automotive and aerospace to consumer electronics and medical devices.The company offers a wide range of services, including rapid prototyping, 3D printing, CNC machining, and more. Their expertise in creating functional prototypes has made them a preferred partner for many manufacturers looking to bring their ideas to life quickly and efficiently. By utilizing advanced materials and state-of-the-art manufacturing processes, the company is able to produce prototypes that are not only functional but also highly accurate and realistic.One of the key advantages of using functional prototypes is the ability to test and validate designs before committing to large-scale production. This can help companies avoid costly mistakes and save time and resources in the long run. By simulating the actual performance of the product, manufacturers can identify potential issues early on and make necessary adjustments to improve the final product.In addition to the practical benefits, functional prototypes also allow for greater creativity and innovation in the design process. With the ability to quickly iterate and modify prototypes, designers can explore different concepts and ideas without the constraints of traditional manufacturing methods. This flexibility can lead to the development of more innovative and cutting-edge products that may not have been possible otherwise.[Company name] has been at the forefront of promoting and advocating for the use of functional prototypes in the manufacturing industry. They have been working closely with their partners to educate and demonstrate the benefits of this technology, and as a result, more and more companies are beginning to adopt this approach in their product development process.As the demand for functional prototypes continues to grow, [Company name] is expanding its capabilities to meet the needs of the market. By investing in advanced technologies and equipment, the company is able to offer even more sophisticated and high-quality prototypes to their customers. They are also continually refining their processes to ensure fast turnaround times and cost-effective solutions for their clients.In conclusion, the use of functional prototypes is rapidly gaining momentum in the manufacturing industry, and [Company name] is leading the charge in this trend. With their expertise and commitment to innovation, they have been able to help many companies bring their ideas to life and stay ahead of the competition. As the industry continues to evolve, functional prototypes are likely to become an essential part of the product development process, and [Company name] will undoubtedly be at the forefront of this exciting new era in manufacturing.

Expert Tips for Complex Metal Fabrication

Complex Metal Fabrication is a leading provider of custom metal fabrication and machining services. With over {XX} years of industry experience, the company has developed a reputation for delivering high-quality products and solutions to customers in a wide range of industries. From prototype development to full-scale production, Complex Metal Fabrication has the capabilities and expertise to meet the unique needs of each client.The company specializes in a variety of metal fabrication processes, including welding, laser cutting, and CNC machining. Their state-of-the-art facility is equipped with the latest technology and machinery, allowing them to tackle even the most complex and intricate projects. Whether it's a custom component for aerospace applications or precision parts for the medical industry, Complex Metal Fabrication has the knowledge and resources to deliver exceptional results.One of the key differentiators for Complex Metal Fabrication is their commitment to quality and precision. They understand that their customers rely on their products for critical applications, and they take that responsibility seriously. The company has implemented strict quality control measures throughout the production process, ensuring that each part meets the highest standards of performance and reliability.In addition to their technical expertise, Complex Metal Fabrication also prides themselves on their collaborative approach to customer service. They work closely with each client to understand their specific requirements and develop tailored solutions to meet their needs. By maintaining open lines of communication and providing ongoing support, they aim to build long-term partnerships with their customers.Complex Metal Fabrication serves a diverse customer base, including companies in the aerospace, automotive, defense, and medical industries. They have the flexibility and agility to adapt to the unique demands of each market, and they are committed to staying ahead of industry trends and advancements. Whether it's leveraging new materials or exploring innovative fabrication techniques, the company is always looking for ways to enhance their capabilities and deliver added value to their customers.As a testament to their ongoing commitment to excellence, Complex Metal Fabrication has recently invested in new technology and expanded their production capacity. The company has added state-of-the-art equipment to their facility, allowing them to take on larger and more complex projects. They have also made strategic hires to further strengthen their team of skilled professionals, ensuring that they have the talent and expertise to meet the evolving needs of their customers.Looking ahead, Complex Metal Fabrication remains focused on driving innovation and pushing the boundaries of what is possible in metal fabrication. They are exploring new opportunities in additive manufacturing and next-generation materials, positioning themselves at the forefront of industry advancements. By staying at the cutting-edge of technology and continuing to prioritize customer satisfaction, the company is poised for continued success and growth in the years to come.In conclusion, Complex Metal Fabrication is a leader in the custom metal fabrication and machining industry, with a proven track record of delivering exceptional products and solutions. Their dedication to quality, precision, and customer service sets them apart in the market, and their ongoing investments in technology and talent position them for future success. With a diverse customer base and a commitment to innovation, Complex Metal Fabrication is well-positioned to continue exceeding the expectations of their clients and driving the industry forward.

Stamped Sheet Metal Parts: Benefits, Uses, and Applications

[Company Introduction]: Based in [Location], [Company Name] is a leading manufacturer of precision stamped sheet metal parts for a wide range of industries. With over [number] years of experience in the industry, the company is known for its high-quality products, advanced manufacturing techniques, and commitment to customer satisfaction. [Company Name] offers a comprehensive range of stamped sheet metal parts, including brackets, clips, enclosures, and more. The company's state-of-the-art facilities and skilled team allow them to meet the unique needs of their customers, providing custom solutions and quick turnaround times.[News Content]:Stamped Sheet Metal Parts: Enhancing Manufacturing EfficiencyIn today's fast-paced and demanding manufacturing industry, precision and efficiency are key factors in ensuring success. As a leading manufacturer of stamped sheet metal parts, [Company Name] plays a crucial role in helping companies across various industries enhance their manufacturing processes.Stamped sheet metal parts are integral components used in a wide array of products, from automotive parts to electronic devices. They are essential for ensuring the structural integrity, durability, and functionality of these products. With its expertise and cutting-edge manufacturing capabilities, [Company Name] has established itself as a trusted partner for businesses looking to source high-quality stamped sheet metal parts.One of the key strengths of [Company Name] is its ability to provide custom solutions to meet the specific needs of its clients. By leveraging advanced manufacturing techniques and the latest technology, the company is able to produce stamped sheet metal parts with unparalleled precision and consistency. Whether it's a unique design requirement or a tight production deadline, [Company Name] is equipped to deliver top-notch solutions that meet and exceed customer expectations.Furthermore, [Company Name] prides itself on its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of industry trends and technological advancements. This proactive approach allows [Company Name] to offer its clients the latest advancements in stamped sheet metal parts, ensuring that they benefit from the most efficient and cost-effective solutions.In addition to its technical prowess, [Company Name] places a strong emphasis on customer satisfaction. The company's team of skilled professionals works closely with clients to understand their unique requirements and provide tailored solutions. From the initial design phase to the final delivery of the stamped sheet metal parts, [Company Name] maintains open lines of communication and a transparent approach, ensuring that customers are fully satisfied with the end product.As the manufacturing industry continues to evolve, the demand for high-quality stamped sheet metal parts is expected to grow. With its proven track record of excellence, [Company Name] is well-positioned to meet this growing demand and provide industry-leading solutions to its clients.In conclusion, stamped sheet metal parts are integral to the manufacturing process, and [Company Name] is at the forefront of delivering high-quality, custom solutions to meet the needs of various industries. With its commitment to innovation, precision, and customer satisfaction, [Company Name] is poised to continue playing a pivotal role in enhancing manufacturing efficiency for years to come.