High-Quality Silicone Rubber Molding for Various Applications

By:Admin

One company that has become a leader in silicone rubber molding is {Company Name}. With over 20 years of experience in the industry, {Company Name} has established itself as a trusted supplier of silicone rubber products to a diverse range of clients, including those in the automotive, aerospace, medical, and consumer electronics industries. The company is known for its commitment to quality, precision, and customer satisfaction, and has earned a reputation for delivering innovative solutions to its clients' unique manufacturing challenges.

At the heart of {Company Name}'s success is its state-of-the-art manufacturing facility, which is equipped with the latest technology and machinery for silicone rubber molding. The company's team of skilled engineers and technicians are experienced in working with a wide range of silicone materials, and are able to provide custom solutions to meet each client's specific requirements. Utilizing advanced CAD/CAM software, {Company Name} is able to quickly design and prototype new products, and is able to efficiently produce high volumes of precision-molded silicone components.

One of the key advantages of silicone rubber molding is its ability to produce complex shapes and intricate designs with high precision and accuracy. This makes it an ideal manufacturing process for producing custom gaskets, seals, and other components that require tight tolerances and exacting specifications. Silicone rubber is also known for its excellent resistance to extreme temperatures, chemicals, and environmental conditions, making it an ideal material for a wide range of applications. From automotive gaskets to medical device components, silicone rubber molding offers a versatile and reliable solution for a variety of industries.

In addition to its expertise in silicone rubber molding, {Company Name} also offers a range of value-added services to its clients, including product design and development, material selection and testing, and quality assurance and testing. The company is committed to ensuring that all of its products meet the highest standards of quality and performance, and works closely with its clients throughout the entire manufacturing process to ensure that their exact specifications are met.

{Company Name} prides itself on its ability to provide innovative solutions to its clients' manufacturing challenges, and is continuously investing in new technologies and processes to further enhance its capabilities. With a focus on quality, precision, and customer satisfaction, {Company Name} is dedicated to delivering exceptional silicone rubber products that meet and exceed its clients' expectations.

Overall, silicone rubber molding is a highly effective and versatile manufacturing process that offers a wide range of benefits for a variety of industries. {Company Name} has established itself as a leader in this field, and has demonstrated its expertise in delivering high-quality silicone rubber products to its clients. With its state-of-the-art facility and commitment to innovation, {Company Name} is well positioned to continue providing innovative solutions and exceptional service to its clients for many years to come.

Company News & Blog

High-Quality Elastomer Injection Molding: Benefits and Applications

Elastomer Injection Molding is a crucial process in the manufacturing industry, and it is increasingly becoming popular due to its efficiency and effectiveness in producing high-quality elastomer products. One of the leading companies at the forefront of Elastomer Injection Molding is {Company Name}.{Company Name} is a renowned manufacturer of elastomer products, and their expertise in Elastomer Injection Molding has made them a trusted partner for various industries, including automotive, aerospace, medical, and consumer goods. With their state-of-the-art facilities and cutting-edge technology, {Company Name} has been able to meet the diverse needs of their clients and deliver top-notch elastomer products that meet the highest industry standards.Elastomer Injection Molding is a process that involves injecting molten elastomer material into a mold cavity, where it is then allowed to cool and solidify, taking the shape of the mold. This process allows for the production of complex and intricate elastomer products with high precision and consistency. {Company Name} has mastered this process, and their expertise in Elastomer Injection Molding has enabled them to deliver a wide range of products, including seals, gaskets, O-rings, and custom-molded elastomer parts.One of the key advantages of Elastomer Injection Molding is its ability to produce elastomer products with excellent dimensional stability and tight tolerances. This is essential in industries such as automotive and aerospace, where precision and reliability are paramount. {Company Name} has leveraged their expertise in Elastomer Injection Molding to meet the stringent requirements of these industries, producing elastomer products that can withstand extreme temperatures, pressures, and environmental conditions.Furthermore, Elastomer Injection Molding allows for the use of a wide variety of elastomer materials, including silicone, fluorocarbon, nitrile, and EPDM. {Company Name} has a thorough understanding of these materials and their properties, allowing them to recommend the most suitable elastomer material for each specific application. Whether it's for sealing, cushioning, or dampening, {Company Name} can provide elastomer products that meet the desired performance and functionality requirements.In addition to their expertise in Elastomer Injection Molding, {Company Name} also prides itself on its commitment to quality and customer satisfaction. Their ISO-certified quality management system ensures that every elastomer product that leaves their facility meets the highest quality standards. From the initial design and engineering phase to the final inspection and testing, {Company Name} maintains a rigorous quality control process to ensure that their products exceed customer expectations.Moreover, {Company Name} is dedicated to staying at the forefront of innovation in Elastomer Injection Molding. They continuously invest in research and development, as well as in the latest manufacturing technologies, to improve their processes and expand their capabilities. This commitment to innovation has enabled {Company Name} to take on complex elastomer molding projects and deliver solutions that push the boundaries of what is possible with elastomer materials.As the demand for high-performance elastomer products continues to grow across various industries, {Company Name} remains a reliable and trusted partner for companies seeking top-quality elastomer solutions. Their expertise in Elastomer Injection Molding, combined with their dedication to quality and innovation, positions them as a leading manufacturer in the elastomer industry.In conclusion, {Company Name} is a company with a proven track record of excellence in Elastomer Injection Molding. Their commitment to quality, innovation, and customer satisfaction sets them apart as a trusted partner for companies seeking high-quality elastomer products. With their expertise and state-of-the-art facilities, {Company Name} continues to drive the advancement of elastomer technology and provide solutions that meet the evolving needs of the manufacturing industry.

Custom Metal Welding and Bending Services for Box Fabrication

Metal fabrication companies play a crucial role in the manufacturing industry by providing custom metal parts and components for a wide range of applications. One such company that has been making waves in the industry is Metal Box Welding Bending Service.Metal Box Welding Bending Service is a leading provider of metal fabrication services, specializing in welding, bending, and custom metal fabrication. With a team of highly skilled and experienced metal fabricators, the company has built a strong reputation for delivering high-quality and precision-engineered metal components to a diverse clientele.The company's state-of-the-art facility is equipped with the latest technology and machinery, allowing them to take on projects of all sizes and complexities. From small-scale components to large structural steel fabrications, Metal Box Welding Bending Service has the capabilities to meet the unique needs of their clients.One of the key strengths of Metal Box Welding Bending Service is their commitment to quality and customer satisfaction. They understand that each project is unique and requires a tailored approach, which is why they work closely with their clients from the initial design phase to the final product delivery. This ensures that the finished product meets the highest standards of quality and precision.In addition to their welding and bending services, Metal Box Welding Bending Service also offers a range of secondary services such as cutting, punching, and finishing. This comprehensive approach to metal fabrication allows them to provide a one-stop solution for their clients, saving them time and resources by eliminating the need to outsource various processes.The company's dedication to excellence has earned them a loyal customer base and a reputation for delivering results that exceed expectations. Whether it's a custom metal part for a specialized application or a large-scale metal fabrication project, Metal Box Welding Bending Service has the expertise and capabilities to get the job done right.With a focus on continuous improvement and staying ahead of industry trends, Metal Box Welding Bending Service is always looking for ways to enhance their capabilities and expand their service offering. They invest in ongoing training for their team, as well as new technology and equipment, to ensure they can continue to meet the evolving needs of their clients.The success of Metal Box Welding Bending Service can also be attributed to their strong leadership and company culture. The team is dedicated to upholding the highest standards of professionalism, integrity, and reliability in all their operations. This commitment to excellence has not only earned them the trust of their clients but has also positioned them as a leader in the metal fabrication industry.Looking ahead, Metal Box Welding Bending Service is poised for continued growth and success. With a solid foundation based on quality, innovation, and customer satisfaction, they are well-positioned to take on new challenges and expand their presence in the market.In conclusion, Metal Box Welding Bending Service has established itself as a reputable and reliable partner for custom metal fabrication needs. With a focus on quality, precision, and customer satisfaction, they continue to set the bar high for metal fabrication services. Whether it's welding, bending, cutting, or finishing, Metal Box Welding Bending Service is the go-to choice for a wide range of metal fabrication needs.

Understanding the Process and Benefits of Plastic Insert Molding

Plastic Insert Molding Offers Enhanced Precision and Efficiency for Company {}In today's fast-paced manufacturing environment, precision and efficiency are key factors in ensuring the success of a company's production process. One method that has gained significant attention in recent years for achieving these goals is plastic insert molding. This advanced manufacturing technique has revolutionized the way companies produce plastic parts by combining precision and efficiency into one seamless process. One company that has adopted this innovative approach to manufacturing is {}.{} is a leading manufacturer in the plastic injection molding industry, specializing in providing high-quality plastic components for a wide range of industries, including automotive, healthcare, consumer goods, and electronics. With a commitment to excellence and a focus on innovation, {} is constantly exploring new technologies and processes to improve the quality and efficiency of its production methods.One of the technologies that has significantly impacted {}'s manufacturing capabilities is plastic insert molding. This process involves molding thermoplastic material around metal or plastic inserts, resulting in a more precise and durable product. By incorporating plastic insert molding into their production process, {} has been able to create complex, multi-material components with a high level of precision and efficiency.One of the key benefits of plastic insert molding is its ability to reduce the need for secondary assembly processes, such as welding or adhesives. This not only saves time and labor costs but also results in a more reliable and consistent end product. {} has capitalized on this advantage by offering its customers a streamlined manufacturing process that delivers high-quality plastic components with shorter lead times and reduced overall production costs.In addition to its efficiency, plastic insert molding also provides improved part consistency and reliability. The process allows for tighter tolerances and better control over material distribution, resulting in parts that are more resistant to wear and tear. This is particularly beneficial for industries such as automotive and healthcare, where the performance and durability of plastic components are critical.Another crucial advantage of plastic insert molding is its ability to create complex geometries and features in a single process. This makes it possible for {} to produce intricate and detailed plastic parts that would be difficult or impossible to achieve with traditional manufacturing methods. As a result, the company is able to offer its customers innovative solutions that meet the evolving demands of their respective industries.{}'s investment in plastic insert molding technology has positioned the company as a leader in the manufacturing of precision plastic components. By leveraging the advantages of this advanced manufacturing process, {} has been able to enhance its production capabilities and expand its product offerings to meet the diverse needs of its customers.With a strong emphasis on quality, innovation, and customer satisfaction, {} is committed to continuing its investment in advanced manufacturing technologies. As the company looks to the future, it remains dedicated to pushing the boundaries of what is possible in plastic component manufacturing, delivering cutting-edge solutions that drive success for its customers.In conclusion, plastic insert molding has revolutionized the way {} produces plastic components, offering enhanced precision, efficiency, and reliability. By embracing this advanced manufacturing technique, {} has solidified its position as a leader in the industry, delivering high-quality plastic parts that meet the diverse needs of its customers. As the company continues to invest in innovative technologies, it is poised to uphold its commitment to excellence and drive success for its customers in the ever-evolving manufacturing landscape.

High-Quality Plastic Injection Tooling: What You Need to Know

Plastic Injection Tooling, a key component in the manufacturing process for a wide range of products, is a critical part of the production line for many companies. It is essential for creating high-quality, precision-engineered plastic components that are used in various industries such as automotive, aerospace, medical, consumer goods, and more. With the market demand for plastic injection tooling on the rise, it's important for companies to have access to reliable and efficient tools that can meet their production needs.{Company Name} is a leading provider of plastic injection tooling solutions, offering a wide range of services to help companies optimize their production processes. From design and engineering to prototype development and mass production, {Company Name} delivers high-quality, cost-effective solutions to meet the unique needs of each customer. With a team of experienced engineers and state-of-the-art facilities, {Company Name} is committed to providing top-notch plastic injection tooling that exceeds customer expectations.One of the key advantages of {Company Name}'s plastic injection tooling solutions is their ability to work with a variety of materials, including traditional thermoplastics, engineering resins, and high-performance materials. This flexibility allows customers to choose the best material for their specific application, whether it's for a high-stress automotive component or a delicate medical device. {Company Name} also offers expertise in designing complex tooling systems that can produce intricate parts with tight tolerances, giving customers the confidence that their products will meet the highest quality standards.In addition to their technical expertise, {Company Name} prides itself on its commitment to customer service and satisfaction. Their team works closely with each customer to understand their unique requirements and objectives, providing personalized solutions that meet their needs and budget. Whether it's a small prototype run or a large-scale production project, {Company Name} is dedicated to delivering the right plastic injection tooling solution on time and within budget.{Company Name} has also invested in cutting-edge technology and equipment to ensure that they stay at the forefront of the industry. Their state-of-the-art manufacturing facilities are equipped with the latest CNC machines, EDM equipment, and mold flow analysis software, allowing them to produce high-quality tooling with precision and efficiency. This technology, combined with their team's expertise, enables {Company Name} to deliver top-notch plastic injection tooling solutions that help their customers stay competitive in the marketplace.As the demand for plastic injection tooling continues to grow, {Company Name} remains committed to innovation and continuous improvement. They are constantly exploring new materials, technologies, and processes to enhance their capabilities and deliver better value to their customers. By staying ahead of industry trends and investing in the latest tools and equipment, {Company Name} aims to remain a trusted partner for companies looking for reliable and efficient plastic injection tooling solutions.Overall, the continued success of {Company Name} is a testament to their dedication to quality, innovation, and customer satisfaction. As the demand for plastic injection tooling continues to rise, companies can rely on {Company Name} to deliver the high-quality, cost-effective solutions they need to stay competitive in the marketplace. With their expertise, state-of-the-art facilities, and commitment to excellence, {Company Name} is well-positioned to meet the evolving needs of the industry and continue to be a leader in the plastic injection tooling market.

Exploring the Benefits of Rapid Prototyping in Product Development

Rapid Prototype Revolutionizing Manufacturing ProcessesIn today's fast-paced world, the demand for speedy and efficient manufacturing processes is at an all-time high. This is where Rapid Prototype comes into play, offering innovative solutions that are revolutionizing the way companies design and develop products.Rapid Prototype specializes in providing cutting-edge prototyping services to a wide range of industries, including automotive, aerospace, medical, and consumer goods. With a team of experienced engineers and state-of-the-art technology, Rapid Prototype has earned a reputation for delivering high-quality prototypes in record time.One of the key factors that sets Rapid Prototype apart is its commitment to using the latest 3D printing technology. This allows the company to create prototypes with incredible precision and detail, giving clients a realistic representation of their final product. By leveraging 3D printing, Rapid Prototype is able to drastically reduce the time and cost associated with traditional prototyping methods, providing clients with a competitive edge in their respective industries.Furthermore, Rapid Prototype offers a wide range of materials for prototyping, including plastics, metals, and composites, ensuring that their clients can test and evaluate different designs and materials before committing to mass production. This flexibility is crucial in helping companies refine their products and ensure that they meet the highest standards of quality and performance.In addition to its prototyping services, Rapid Prototype also offers design and engineering support to help clients bring their ideas to life. The company's team of experts works closely with clients to understand their requirements and provide valuable insights and recommendations throughout the prototyping process. This collaborative approach has allowed Rapid Prototype to build long-lasting partnerships with leading companies in various industries.One such success story involves a leading automotive manufacturer that turned to Rapid Prototype for assistance in developing a new car part. The manufacturer was facing significant challenges in prototyping the complex component, and Rapid Prototype was able to deliver a fully functional prototype within a matter of days. This accelerated timeline allowed the manufacturer to test the part in real-world conditions and make necessary design adjustments before moving into mass production, ultimately saving them time and money.Rapid Prototype's commitment to innovation and customer satisfaction has led to its rapid growth and expansion in recent years. The company has continued to invest in the latest technologies and equipment to further improve its prototyping capabilities, ensuring that its clients have access to the best resources available.Looking ahead, Rapid Prototype is poised to continue its trajectory of success, with plans to further expand its services and reach new markets. The company's dedication to pushing the boundaries of prototyping and manufacturing is not only benefiting its clients, but also contributing to the overall advancement of the industry.In conclusion, Rapid Prototype's commitment to excellence and innovation has cemented its position as a leader in the prototyping industry. By leveraging cutting-edge 3D printing technology, offering a diverse range of materials, and providing expert engineering support, Rapid Prototype is empowering companies to bring their ideas to life with unprecedented speed and efficiency. As the demand for rapid prototyping continues to grow, Rapid Prototype is well-positioned to remain at the forefront of this transformative industry.

High-Quality Aerospace Parts for Precision Engineering

Precision Aerospace Parts, a leading provider of high-quality aerospace components, is proud to announce the expansion of its manufacturing capabilities with the addition of a state-of-the-art facility. The new facility will further enhance the company's ability to deliver precision-engineered parts to its customers in the aerospace industry.With over 20 years of experience in the aerospace manufacturing business, Precision Aerospace Parts has earned a reputation for excellence in delivering high-quality, reliable components. The company's commitment to precision and quality has made it a trusted partner for some of the leading aerospace companies in the world.The new facility, located in a strategic area known for its strong manufacturing infrastructure, is equipped with the latest technologies and advanced machinery. This investment in state-of-the-art equipment demonstrates Precision Aerospace Parts' dedication to staying at the forefront of the industry and meeting the ever-evolving needs of its customers."We are excited to announce the opening of our new facility, which represents a significant milestone in our company's growth," said the CEO of Precision Aerospace Parts. "This expansion will not only allow us to increase our production capacity but also improve our efficiency and flexibility in meeting the demands of our customers. We are committed to providing the highest quality aerospace components and this new facility will further strengthen our ability to do so."The new facility will focus on producing a wide range of precision aerospace parts, including complex machined components, assemblies, and structural parts. With an emphasis on meeting stringent aerospace industry standards, the facility will adhere to the highest quality and safety protocols to ensure the superior reliability and performance of its products.In addition to enhancing its manufacturing capabilities, Precision Aerospace Parts is also dedicated to investing in its people. The company is committed to providing ongoing training and development opportunities for its employees, ensuring that they are equipped with the skills and knowledge necessary to produce top-quality aerospace components.Furthermore, Precision Aerospace Parts is deeply committed to sustainability and environmental responsibility. The new facility has been designed with energy-efficient systems and environmentally friendly practices in mind, aligning with the company's goal of minimizing its environmental footprint and contributing to a more sustainable future.As the aerospace industry continues to evolve and demand for advanced components grows, Precision Aerospace Parts is well-positioned to meet the needs of its customers. The company's dedication to quality, innovation, and customer satisfaction sets it apart as a trusted partner in the aerospace manufacturing sector.With the opening of its new facility, Precision Aerospace Parts looks forward to further strengthening its position as a leading provider of precision-engineered aerospace components. The investment in advanced manufacturing capabilities reflects the company's unwavering commitment to excellence and its determination to continue exceeding the expectations of its customers.As Precision Aerospace Parts continues to expand its footprint in the aerospace industry, the opening of the new facility marks a significant milestone in the company's journey towards continued growth and success. The company's dedication to quality, innovation, and sustainability positions it as a valuable partner for the aerospace industry's present and future needs.

Understanding the Importance of Precision in CNC Machining

CNC Precision, a leading precision machining company, has recently announced its expansion plans to meet the growing demand for its services in the manufacturing industry. The company, which specializes in providing high-quality CNC machining, has built a reputation for delivering precision parts and components to a wide range of industries, including aerospace, automotive, medical, and electronics.With the increasing demand for precision-machined parts and components, CNC Precision has recognized the need to expand its operations in order to better serve its customers. The company has invested in state-of-the-art equipment and technology to increase its production capacity and capabilities, allowing it to take on larger and more complex projects. This expansion will enable CNC Precision to meet the evolving needs of its customers and maintain its position as a market leader in the precision machining industry."We are excited to announce our expansion plans as we strive to meet the growing demand for our precision machining services," said the CEO of CNC Precision. "Our investment in new technology and equipment will enable us to provide our customers with even higher quality products and faster turnaround times. This expansion is a testament to our commitment to being a reliable and innovative partner for our customers."In addition to increasing its production capacity, CNC Precision is also focused on expanding its workforce to accommodate the growing demand for its services. The company is actively recruiting skilled machinists, engineers, and support staff to join its team and contribute to its continued success. By investing in its team and facilities, CNC Precision aims to continue providing exceptional service and value to its customers.As part of its expansion plans, CNC Precision is also exploring opportunities to broaden its customer base and expand its presence in new markets. The company is actively seeking partnerships and collaborations with other organizations in the manufacturing industry to further enhance its capabilities and reach. By forging strategic alliances, CNC Precision aims to leverage its expertise and resources to deliver added value to its customers and accelerate its growth.CNC Precision's commitment to innovation, quality, and customer satisfaction has been the driving force behind its success. The company's dedication to investing in advanced technology, expanding its capabilities, and attracting top talent has positioned it as a trusted partner for a wide range of industries. As CNC Precision continues to expand and evolve, it remains focused on delivering precision solutions that meet the unique needs of its customers.The expansion of CNC Precision comes at a time when the manufacturing industry is experiencing rapid growth and transformation. With increasing demand for precision-machined parts and components, companies are seeking reliable partners that can deliver high-quality products with quick turnaround times. CNC Precision's expansion plans align with the industry's needs, positioning the company for continued success and leadership in the precision machining sector.As CNC Precision continues to expand its operations and capabilities, it remains dedicated to delivering exceptional quality and service to its customers. The company's expansion plans underscore its commitment to meeting the evolving needs of the manufacturing industry and driving innovation in precision machining. With its growing team, advanced technology, and strategic partnerships, CNC Precision is well-positioned to continue setting the standard for precision machining and delivering value to its customers.

High-Quality and Efficient Short Run Injection Molding Services

Short Run Injection Molding, a leading provider of high-quality custom plastic injection molding, has been making waves in the industry with their innovative and efficient manufacturing processes. With a focus on short run production, the company has been able to consistently deliver top-notch products to their clients while maintaining a quick turnaround time.Founded in [year], Short Run Injection Molding has quickly risen to prominence in the industry. Their state-of-the-art facility is equipped with the latest in injection molding technology, allowing them to produce complex and intricate parts with precision and accuracy. The company's team of highly skilled engineers and technicians are dedicated to delivering the best possible solutions for their clients' unique needs.One of the key factors that set Short Run Injection Molding apart from their competitors is their ability to handle short run production effectively. Unlike traditional molding processes that require high-volume production to be cost-effective, Short Run Injection Molding specializes in producing small to medium batch sizes, making it an ideal solution for clients with limited production needs.The company's short run injection molding process is a highly efficient and cost-effective method of manufacturing plastic parts. By utilizing advanced mold-making techniques and cutting-edge materials, Short Run Injection Molding is able to produce parts that meet the strictest quality standards while minimizing waste and reducing production costs. This approach allows clients to benefit from fast production turnaround times and lower overall production costs, setting Short Run Injection Molding apart as a leader in the industry.In addition to their expertise in short run production, Short Run Injection Molding also offers a wide range of services to meet the diverse needs of their clients. From concept and design assistance to prototyping and full-scale production, the company is committed to providing comprehensive solutions to their clients' manufacturing challenges. Their dedication to quality and customer satisfaction has earned them a reputation as a trusted partner in the industry.Short Run Injection Molding also prides itself on its commitment to sustainability and environmental responsibility. The company utilizes advanced recycling and waste reduction techniques to minimize their environmental impact, ensuring that their manufacturing processes are as eco-friendly as possible. This dedication to sustainability not only benefits the environment but also allows Short Run Injection Molding to offer clients cost-effective and sustainable solutions for their plastic injection molding needs.With their innovative approach to short run production, commitment to quality, and dedication to sustainability, Short Run Injection Molding has established itself as a leader in the industry. The company's ability to consistently deliver high-quality products with quick turnaround times has made them a preferred choice for clients across a wide range of industries.Moving forward, Short Run Injection Molding remains focused on pushing the boundaries of injection molding technology and delivering even greater value to their clients. With a continued commitment to excellence and a passion for innovation, the company is poised to continue their rapid growth and solidify their position as a top provider of custom plastic injection molding solutions. As the industry evolves, Short Run Injection Molding will undoubtedly remain at the forefront, setting new standards for quality, efficiency, and sustainability in the manufacturing of plastic parts.

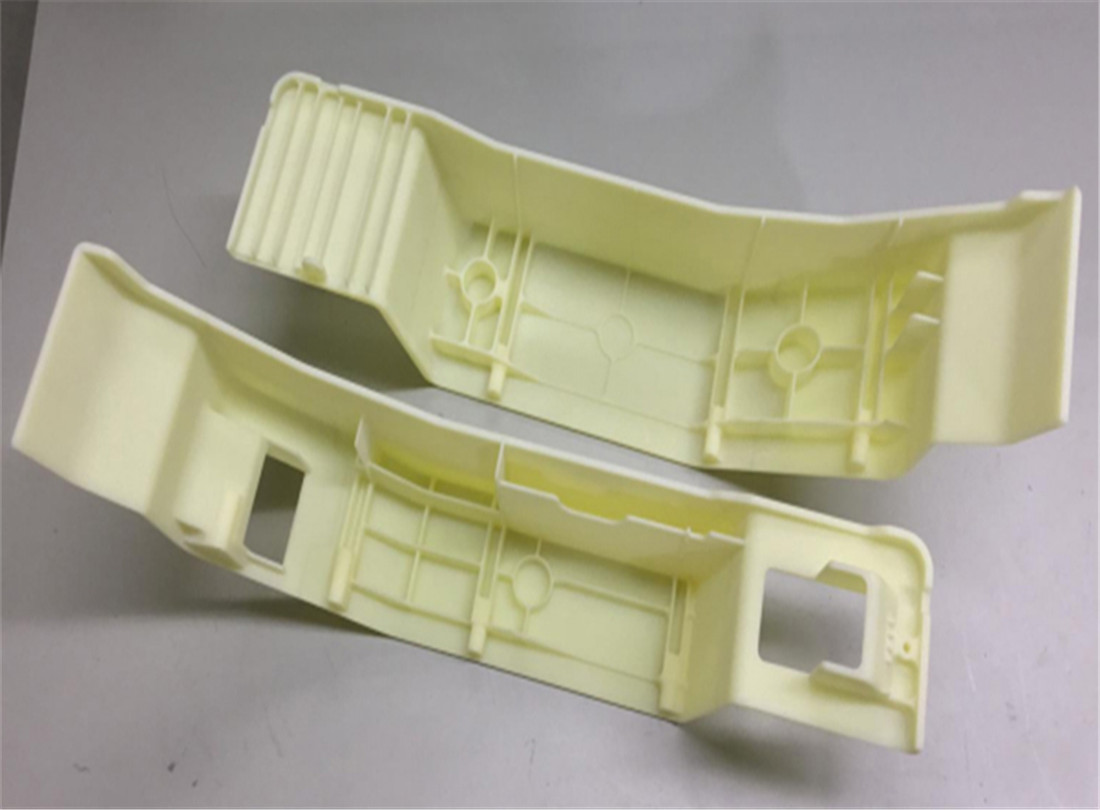

New Fully Functional Prototype Revealed for Innovative Technology

Fully Functional Prototype Unveiled by Innovative Tech CompanyIn an exciting development in the tech world, [Company Name] has unveiled a fully functional prototype that showcases the company’s cutting-edge technology and innovative approach to product development. This prototype represents a major milestone for the company and has generated significant excitement within the industry.[Company Name] is a pioneering tech company known for its groundbreaking advancements in the fields of artificial intelligence, robotics, and smart devices. The company has a strong reputation for pushing the boundaries of what is possible and continues to be at the forefront of technological innovation.The newly unveiled prototype is a testament to the company’s commitment to developing advanced and practical solutions to real-world problems. It features state-of-the-art hardware and software, and incorporates the latest advancements in AI and machine learning technology. The prototype is designed to provide users with a seamless and intuitive experience, and showcases the company’s dedication to creating products that are both functional and user-friendly.One of the key features of the prototype is its ability to [insert key feature]. This innovative technology has the potential to revolutionize the way [insert industry] operates, and has already garnered significant interest from industry experts and potential customers alike.The unveiling of this fully functional prototype represents a significant achievement for [Company Name], and is a testament to the hard work and dedication of the company’s talented team of engineers and designers. The company has invested considerable time and resources into the development of this prototype, and the results speak for themselves.In addition to its impressive technical capabilities, the prototype also boasts a sleek and modern design that is sure to appeal to tech enthusiasts and early adopters. The company has prioritized both form and function in the development of this prototype, and the result is a product that is not only highly advanced, but also aesthetically pleasing.The unveiling of this prototype has generated significant buzz within the tech industry, with many industry experts and analysts expressing their excitement about the potential impact of this technology. The prototype is expected to be a game-changer in the [insert industry] and has the potential to set a new standard for innovation in the field.[Company Name] has a track record of success in bringing cutting-edge technologies to market, and the unveiling of this fully functional prototype is further proof of the company’s ongoing commitment to pushing the boundaries of what is possible. The company has already begun discussions with potential partners and collaborators, and is exploring opportunities to bring this technology to market in the near future.The release of this fully functional prototype is a significant moment for [Company Name], and represents a major step forward in the company’s ongoing mission to revolutionize the tech industry. The company’s dedication to innovation and its relentless pursuit of excellence have once again been demonstrated with the unveiling of this groundbreaking prototype.As the tech industry continues to evolve at a rapid pace, [Company Name] remains at the forefront of innovation, leading the way with its groundbreaking advancements and commitment to pushing the boundaries of what is possible. The unveiling of this fully functional prototype is a testament to the company’s continued success and to its position as a true industry leader.

The Benefits of Complex Injection Molding technology

Complex injection molding is an advanced manufacturing process that allows for the production of highly intricate and detailed plastic parts. This process involves injecting molten plastic into a mold, which is then cooled and solidified to create the desired part. Complex injection molding is a key technology for a wide range of industries, including automotive, electronics, medical devices, and consumer goods.One company that has established itself as a leader in complex injection molding is {}, a global provider of high-quality plastic components and assemblies. With a focus on innovation and precision engineering, {} has earned a reputation for delivering cutting-edge solutions to its customers' most demanding challenges.Founded in {}, {} has grown into a multi-national corporation with facilities in several countries around the world. The company's state-of-the-art manufacturing facilities are equipped with the latest technology and equipment, allowing {} to offer a wide range of complex injection molding capabilities. From micro-molding to large-format molding, {} has the expertise and capabilities to handle the most complex and challenging projects.One of the key strengths of {} is its ability to work closely with customers to develop custom solutions that meet their specific needs. The company's team of engineers and designers use advanced 3D modeling and simulation tools to develop highly optimized mold designs, ensuring that the final products meet the strictest quality and performance requirements. In addition, {}'s expertise in material selection and process optimization allows the company to deliver cost-effective solutions without compromising on quality.{}'s commitment to quality is exemplified by its rigorous quality assurance processes. The company's facilities are certified to the highest industry standards, including ISO 9001 and ISO 13485, ensuring that every part manufactured by {} meets the strictest quality and regulatory requirements. In addition, {} employs advanced inspection and testing techniques to guarantee the integrity and performance of its products, providing customers with added confidence in the reliability of their components.In addition to its technical expertise, {} is also known for its dedication to sustainability and environmental responsibility. The company has implemented a range of initiatives to reduce its environmental impact, including energy-efficient manufacturing processes, waste reduction programs, and the use of recyclable materials. By incorporating sustainable practices into its operations, {} is able to deliver high-quality products while minimizing its footprint on the environment.Looking ahead, {} is well-positioned to continue its leadership in complex injection molding. The company is investing in new technologies and capabilities to expand its offerings and serve an even broader range of industries and applications. In addition, {} continues to invest in its people, with ongoing training and development programs to ensure that its team remains at the forefront of the industry.As the demand for complex plastic components continues to grow, {} is poised to play a key role in shaping the future of manufacturing. With its unwavering commitment to quality, innovation, and sustainability, {} is a trusted partner for companies looking to bring their most complex and challenging projects to life. With its advanced capabilities and customer-focused approach, {} is well-equipped to meet the evolving needs of the market and drive the next generation of complex injection molding solutions.