High-Quality Steel Stamping Parts for Various Applications

By:Admin

With a focus on quality and innovation, Steel Stamping Parts has built a solid reputation as a leading supplier of stamped steel parts for a wide range of industries, including automotive, aerospace, electronics, and more. Their commitment to excellence and dedication to customer satisfaction have earned them the trust and loyalty of many esteemed clients around the world.

The company's extensive capabilities and expertise in steel stamping allow them to produce a diverse range of parts, from simple components to complex assemblies. Their advanced production equipment and cutting-edge technology enable them to tackle even the most challenging projects with ease, ensuring that they consistently deliver top-notch products that meet or exceed industry standards.

In addition to their manufacturing prowess, Steel Stamping Parts is also known for their relentless pursuit of continuous improvement and innovation. They invest heavily in research and development to stay ahead of the curve and adapt to the ever-evolving needs of the market. This forward-thinking approach has enabled them to introduce new and improved processes, materials, and designs that push the boundaries of what is possible in the world of steel stamping.

Moreover, the company places great emphasis on environmental sustainability and social responsibility. They adhere to strict environmental regulations and standards in their manufacturing processes, and actively seek out opportunities to minimize their environmental footprint. They also prioritize the health and safety of their employees, creating a positive and empowering work environment that fosters personal growth and professional development.

With a strong commitment to excellence, integrity, and customer satisfaction, Steel Stamping Parts continues to be a trusted partner for businesses seeking top-quality stamped steel parts. Their unwavering dedication to quality, innovation, and sustainability sets them apart in the industry, and it's no wonder why they are the go-to choice for many discerning companies worldwide.

In the wake of their recent success and continued expansion, Steel Stamping Parts is poised to elevate their offerings to even greater heights. They have plans to further enhance their production capabilities, invest in advanced technology, and expand their reach into new markets. With their proven track record and unwavering commitment to excellence, the future looks bright for Steel Stamping Parts as they continue to set the benchmark for excellence in the industry.

For businesses and industries in need of high-quality stamped steel parts, Steel Stamping Parts is the name to trust. With their unparalleled expertise, cutting-edge facilities, and unwavering dedication to excellence, they are well-positioned to meet the diverse needs of their customers and contribute to the success of their business partners across the globe. As they continue to innovate, evolve, and set new standards, it's clear that Steel Stamping Parts is a force to be reckoned with in the world of steel stamping.

Company News & Blog

Advanced 5-Axis Lathe Innovations in Machining Technology

The 5 Axis Lathe has been making waves in the manufacturing industry, and for good reason. This cutting-edge technology offers precision and efficiency, revolutionizing the way that parts and components are fabricated. With its advanced capabilities, the 5 Axis Lathe has quickly become a must-have for companies striving to stay ahead of the competition.One company that is leading the way in the adoption of this technology is {Company}. With a strong commitment to innovation and quality, {Company} has recognized the potential of the 5 Axis Lathe and has fully embraced its capabilities. This forward-thinking approach has allowed {Company} to deliver superior products to their customers while maintaining a competitive edge in the market.The 5 Axis Lathe is a sophisticated piece of equipment that offers unmatched versatility and precision. Unlike traditional lathes that operate on three axes, the 5 Axis Lathe can move in five different directions, allowing for more complex and intricate machining processes. This opens up a world of possibilities for creating parts and components with incredibly tight tolerances and intricate geometries.In addition to its enhanced capabilities, the 5 Axis Lathe also offers significant time and cost savings. Thanks to its ability to perform multiple operations in a single setup, it reduces the need for manual intervention and minimizes the risk of human error. This not only speeds up the production process but also improves the overall quality of the finished product.{Company} has fully leveraged these benefits to improve their manufacturing processes and deliver exceptional results to their customers. By investing in the latest technologies, {Company} has positioned itself as a leader in the industry, setting new standards for precision and efficiency. The 5 Axis Lathe has played a key role in this success, allowing {Company} to take on more complex projects and deliver superior products in a shorter timeframe.Furthermore, the 5 Axis Lathe has enabled {Company} to expand their capabilities and take on projects that were previously deemed too challenging. Its ability to machine complex shapes and contours with ease has opened up new opportunities for {Company} to diversify their product offerings and serve a wider range of industries and applications. This has not only strengthened {Company}'s position in the market but has also allowed them to explore new avenues for growth and expansion.One of the key advantages of the 5 Axis Lathe is its ability to reduce setup times and increase production efficiency. With its advanced technology and automated features, {Company} has been able to streamline their workflows and maximize the utilization of their equipment. This has not only improved their overall productivity but has also allowed them to take on more orders and meet the growing demands of their customers.Another noteworthy aspect of the 5 Axis Lathe is its ability to achieve precise and consistent results, even when working with the most challenging materials. {Company} has capitalized on this capability to produce high-quality components that meet the strictest industry standards. This has further solidified {Company}'s reputation as a trusted manufacturer, known for delivering top-notch products that exceed customer expectations.Looking ahead, {Company} is committed to continuing their investment in advanced manufacturing technologies, including the 5 Axis Lathe. By staying at the forefront of innovation, {Company} aims to remain a leader in the industry and continue providing their customers with exceptional products and services.In conclusion, the 5 Axis Lathe has proven to be a game-changer for companies like {Company}, offering unparalleled precision, efficiency, and versatility. As {Company} continues to leverage this technology to its full potential, they are setting new benchmarks for quality and performance in the manufacturing industry. With their unwavering commitment to innovation, {Company} is well-positioned to thrive in the dynamic and competitive landscape of modern manufacturing.

High-quality Sheet Metal Laser Cutting and Welding Parts: A Complete Guide

[Company Name] Expands its Capabilities with Sheet Metal Laser Cutting and Welding[City, State] – [Company Name], a leading provider of precision metal fabrication, is proud to announce the addition of sheet metal laser cutting and welding to its list of capabilities. This investment in new technology represents [Company Name]'s commitment to meeting the evolving needs of its customers.With the addition of sheet metal laser cutting, [Company Name] can now offer more precise and intricate cuts for a variety of materials, including steel, aluminum, and stainless steel. This new capability allows for faster production times and increased productivity, ultimately benefiting the company's clients.In addition to laser cutting, [Company Name] has also expanded its welding capabilities. The company now offers a range of welding techniques, including MIG and TIG welding, to create high-quality, durable metal parts. This enhancement will allow [Company Name] to provide a more comprehensive and integrated solution for its customers' metal fabrication needs.[Company Name] has a long-standing reputation for delivering precision metal fabrication solutions to a diverse range of industries, including automotive, aerospace, and medical equipment manufacturing. The company's expertise in producing complex metal parts has earned it the trust of its clients and has established it as a preferred supplier in the industry.With the addition of sheet metal laser cutting and welding, [Company Name] can now offer an even more comprehensive suite of services to its customers. The company's state-of-the-art equipment and highly skilled workforce ensure that it can meet the most demanding requirements for precision and quality in metal fabrication."We are excited to add sheet metal laser cutting and welding to our capabilities," said [Spokesperson], [Title] at [Company Name]. "This investment not only demonstrates our commitment to investing in new technology but also our dedication to providing the best possible solutions for our customers. We are confident that these new capabilities will further enhance our position as a leading provider of precision metal fabrication."The addition of sheet metal laser cutting and welding is part of [Company Name]'s ongoing commitment to innovation and continuous improvement. The company continuously seeks out new technologies and techniques to enhance its capabilities and stay ahead of industry trends.As [Company Name] continues to grow and expand, it remains focused on providing its customers with the highest quality metal fabrication solutions. The company's dedication to excellence and customer satisfaction sets it apart in the industry and ensures that it can meet the evolving needs of its clients.For more information about [Company Name] and its capabilities in precision metal fabrication, visit [company website].About [Company Name]:[Company Name] is a leading provider of precision metal fabrication solutions to a diverse range of industries. With a focus on excellence and customer satisfaction, the company has established itself as a preferred supplier for complex metal parts and assemblies. Through continuous investment in new technology and a highly skilled workforce, [Company Name] remains at the forefront of the metal fabrication industry.

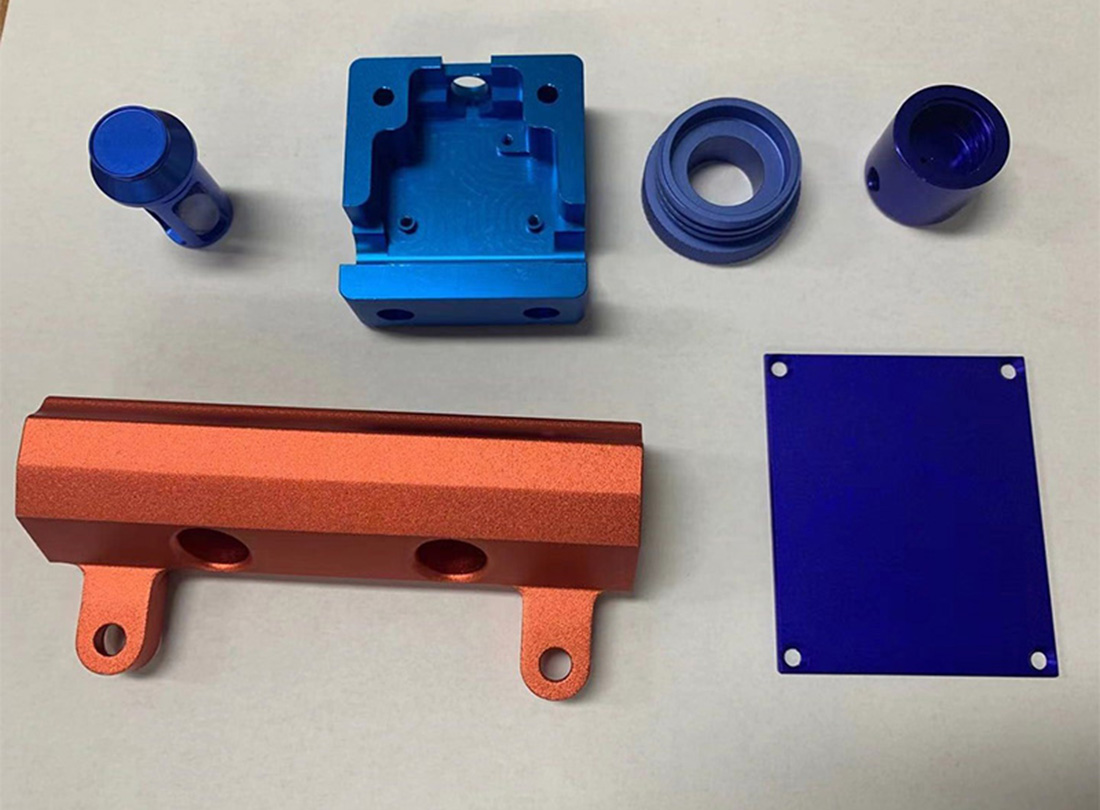

Aluminum CNC Turning Parts for Electroplating - A Complete Guide

Metal manufacturing company, based in [location], has recently announced the launch of their new product, Electroplating Aluminum CNC turning parts. This innovative product has been developed to meet the growing demand for high-quality aluminum parts in various industries such as automotive, aerospace, and electronics.The Electroplating Aluminum CNC turning parts are designed to be versatile and durable, making them suitable for a wide range of applications. With their high precision and tight tolerances, these parts are capable of meeting the strict requirements of modern manufacturing processes. The company has invested in state-of-the-art CNC turning machines to ensure the highest quality and consistency in the production of these parts.In addition to their exceptional quality, the Electroplating Aluminum CNC turning parts also offer excellent corrosion resistance and a sleek, attractive finish. This makes them ideal for use in outdoor, marine, and other harsh environments where protection against corrosion is essential. The electroplating process in which the parts undergo enhances their surface hardness and wear resistance, making them suitable for long-term use.The company's decision to develop and manufacture Electroplating Aluminum CNC turning parts comes as a response to the increasing demand for such products in both domestic and international markets. With the rising trend towards lightweight and high-performance materials in various industries, the company saw an opportunity to expand its product offering and cater to the evolving needs of its customers.Furthermore, the company's extensive experience and expertise in metal manufacturing have allowed them to develop and produce Electroplating Aluminum CNC turning parts that meet the highest industry standards. Their dedicated team of engineers and technicians has worked tirelessly to ensure that these parts deliver exceptional performance and reliability in the most demanding applications.The development and launch of these Electroplating Aluminum CNC turning parts are a testament to the company's commitment to innovation and customer satisfaction. They have continuously invested in research and development to bring cutting-edge products to the market, and the new parts are a reflection of their dedication to staying at the forefront of the industry."We are thrilled to introduce our new Electroplating Aluminum CNC turning parts to the market," said the company's spokesperson. "We believe that these parts will set a new standard for quality and performance in the industry, and we are confident that they will meet the diverse needs of our customers. With our advanced manufacturing capabilities and stringent quality control processes, we are well-positioned to deliver these parts to customers around the world."The Electroplating Aluminum CNC turning parts are now available for purchase, and the company is ready to fulfill orders from customers across different industries. With their strong commitment to customer satisfaction and their ability to tailor solutions to specific requirements, the company is confident that these parts will be well-received in the market.As the demand for high-quality aluminum parts continues to grow, the launch of the Electroplating Aluminum CNC turning parts represents a significant milestone for the company and reinforces its position as a leading provider of metal manufacturing solutions. With their dedication to innovation and excellence, the company is poised to make a lasting impact in the industry and meet the evolving needs of its customers.

High Precision CNC Mill for Superior Machining

High Precision CNC Mill Revolutionizes Manufacturing IndustryWith the continuous advancement in technology, the manufacturing industry is witnessing a significant transformation. The introduction of high precision CNC mills has taken manufacturing to a new level, enabling companies to produce complex and intricate components with unparalleled precision and accuracy. One such company at the forefront of this technological revolution is {}, a leading manufacturer of advanced CNC machines. With a strong focus on innovation and quality, the company has been driving the industry forward with its cutting-edge technology and state-of-the-art solutions.The high precision CNC mill developed by {} has set a new benchmark in the industry, offering unmatched levels of precision and efficiency. This advanced machine is equipped with the latest control systems and cutting-edge software, allowing for seamless integration of complex designs and precise machining operations. The result is a finished product that meets the highest standards of quality and accuracy.One of the key features of the high precision CNC mill is its ability to produce components with tight tolerances and intricate geometries. This has opened up new possibilities for companies across a wide range of industries, including aerospace, automotive, medical, and electronics. The ability to produce complex parts with high precision has enabled manufacturers to push the boundaries of what is possible, leading to innovation and advancements in various sectors.In addition to its precision capabilities, the CNC mill also offers high levels of productivity and efficiency. The advanced automation features and powerful cutting tools allow for rapid production of components, reducing lead times and increasing overall throughput. This has led to significant improvements in manufacturing processes, resulting in higher productivity and cost savings for companies utilizing this technology.Another important aspect of the high precision CNC mill is its versatility. It is capable of machining a wide range of materials, including metals, plastics, and composites, making it suitable for a variety of applications. This flexibility has made the CNC mill a valuable asset for companies looking to expand their capabilities and take on a diverse range of projects.Furthermore, the CNC mill has been designed with user-friendly interfaces and intuitive controls, making it easy for operators to set up, program, and monitor machining operations. This has reduced the learning curve for operators, allowing them to quickly adapt to the new technology and maximize its potential.Moreover, the high precision CNC mill is equipped with advanced safety features to ensure a secure working environment for operators. With built-in sensors and safety protocols, the machine is able to detect and respond to potential hazards, minimizing the risk of accidents and injuries in the workplace.{} has also been proactive in providing comprehensive training and support for its customers, ensuring that they have the knowledge and resources to fully utilize the capabilities of the high precision CNC mill. This commitment to customer satisfaction has helped the company build a strong reputation in the industry, with a track record of delivering reliable and high-performance machines.Overall, the introduction of high precision CNC mills has been a game-changer for the manufacturing industry, offering a level of precision, efficiency, and versatility that was previously unattainable. As technology continues to evolve, the potential for further advancements in CNC machining is limitless, and companies like {} are leading the way in shaping the future of manufacturing.

Custom High Precision Turned Parts for Your Business Needs

The demand for high precision turned parts in the manufacturing industry has been on the rise, and one company has been leading the way in delivering top-quality products to meet this demand. {} is a renowned manufacturer of high precision turned parts, specializing in providing custom solutions for a wide range of industries. With years of experience and expertise in precision engineering, the company has become a trusted partner for businesses seeking top-notch components for their manufacturing processes.The company's commitment to quality and innovation has set them apart in the industry. Their state-of-the-art facilities are equipped with the latest technology and machinery, allowing them to produce turned parts with unmatched precision and accuracy. Their team of skilled engineers and technicians are dedicated to ensuring that every component meets the highest standards of quality and performance.{}'s range of high precision turned parts includes a variety of custom components, including shafts, pins, connectors, and more. These parts are used in a wide range of applications, from automotive and aerospace to medical and electronics. The company works closely with each of their clients to understand their specific needs and requirements, and then delivers tailor-made solutions that meet or exceed expectations.In addition to their precision engineering capabilities, {} prides itself on their commitment to customer service. They understand the importance of delivering products on time and within budget, and strive to maintain clear communication with their clients throughout the manufacturing process. This dedication to customer satisfaction has earned them a loyal and satisfied customer base.Furthermore, {} is dedicated to sustainability and environmental responsibility in their manufacturing processes. They have implemented eco-friendly practices in their facilities, such as reducing waste and energy consumption, and recycling materials whenever possible. This commitment to sustainability aligns with the company's values of integrity and corporate social responsibility.As the demand for high precision turned parts continues to grow, {} is poised to remain at the forefront of the industry. Their reputation for excellence, combined with their dedication to innovation and customer service, positions them as a leading provider of precision components for a wide range of manufacturing applications.In conclusion, {}'s high precision turned parts are a testament to their commitment to quality, innovation, and customer satisfaction. As the manufacturing industry continues to evolve, this company will undoubtedly remain a key player in delivering top-quality components to businesses worldwide. With their state-of-the-art facilities, skilled team, and dedication to sustainability, {} is well-equipped to meet the growing demand for high precision turned parts now and in the future.

Ultimate Guide to Thermoplastic Injection Molding: Everything You Need to Know

[Company Introduction] is a leading manufacturer of thermoplastic injection molding machines, providing innovative and reliable solutions for a wide range of industries. With a strong focus on research and development, the company has established itself as a pioneer in the field of plastic injection technology. By constantly pushing the boundaries of what is possible, has earned a reputation for excellence and continues to lead the way in the industry. [News Content] Thermoplastic injection molding technology has revolutionized the way products are manufactured across various industries. It has significantly improved the efficiency, precision, and cost-effectiveness of producing a wide range of plastic products. The process involves injecting molten material into a mold cavity, where it solidifies to form the desired shape. This method has become increasingly popular due to its ability to produce high-quality and complex parts with ease. One of the key players in the thermoplastic injection molding industry is {}. The company has been at the forefront of developing cutting-edge injection molding machines that are designed to meet the evolving needs of the market. By combining state-of-the-art technology with a strong focus on innovation, has consistently delivered superior solutions to its customers. Recently, {} announced the launch of its latest series of thermoplastic injection molding machines, which are set to raise the bar in terms of performance and reliability. These machines have been meticulously designed to offer enhanced precision, speed, and energy efficiency, making them an ideal choice for manufacturers looking to streamline their production processes. The new series of injection molding machines from {} features a range of advanced capabilities that set them apart from the competition. One of the standout features is their ability to achieve unparalleled levels of precision, ensuring that each molded product meets the highest standards of quality. This is made possible by the incorporation of cutting-edge servo motor technology, which enables precise control of the injection process. In addition to precision, the new machines also offer impressive speed and efficiency. Thanks to their advanced hydraulic systems and optimized design, they can deliver faster cycle times without compromising on quality. This means that manufacturers can significantly increase their production output while maintaining high levels of product consistency. Furthermore, {}'s new series of injection molding machines are engineered for energy efficiency, helping manufacturers reduce their operational costs and environmental impact. By incorporating energy-saving features such as variable frequency drives and advanced cooling systems, these machines consume less power without sacrificing performance. This makes them a sustainable and cost-effective choice for businesses looking to minimize their carbon footprint. Overall, the latest series of thermoplastic injection molding machines from {} represents a significant leap forward in the industry. With their unmatched precision, speed, and energy efficiency, these machines are poised to set a new standard for plastic injection technology. As the demand for high-quality plastic products continues to grow, manufacturers can rely on {} to provide them with the tools they need to stay competitive in the market.

Top Methods for Mould Plastic Injection in Manufacturing

Mould Plastic Injection (MPI) is a leading manufacturer of high-quality plastic injection moulds for a wide range of industries, including automotive, medical, packaging, and consumer goods. With over 20 years of experience in the industry, MPI is known for its innovative approach to mould design and its commitment to delivering top-notch products to its customers.The company utilizes state-of-the-art technology and precision machining to produce moulds that meet the highest industry standards. Whether it's a simple single-cavity mould or a complex multi-cavity mould, MPI has the expertise and capability to deliver a product that exceeds expectations.MPI's team of skilled engineers and designers work closely with clients to understand their specific needs and requirements. They are dedicated to providing customized solutions that address the unique challenges of each project. From initial concept development to final production, MPI is committed to delivering exceptional results on time and within budget.One of the key factors that sets MPI apart from its competitors is its strict quality control measures. The company adheres to rigorous quality assurance protocols throughout the entire manufacturing process to ensure that every mould meets the highest standards of excellence. MPI also conducts thorough testing and inspection of each mould to verify its performance and durability.In addition to its dedication to quality, MPI is also committed to sustainability and environmental responsibility. The company employs eco-friendly manufacturing practices and uses recyclable materials whenever possible. By minimizing waste and reducing energy consumption, MPI strives to minimize its environmental footprint while delivering top-quality products to its customers.MPI's commitment to excellence and customer satisfaction has earned the company a stellar reputation in the industry. Its loyal customer base includes some of the most renowned companies in various sectors, who rely on MPI for their moulding needs. The company's track record of success and customer satisfaction is a testament to its unwavering dedication to quality and innovation.As part of its ongoing commitment to continuous improvement, MPI invests heavily in research and development to stay at the forefront of technological advancements in the industry. The company is constantly exploring new materials, processes, and techniques to enhance its product offerings and provide cutting-edge solutions to its clients.Looking ahead, MPI is poised for further growth and expansion as it continues to build on its success and solidify its position as a leader in the plastic injection moulding industry. With a focus on innovation, quality, and customer satisfaction, MPI is well-equipped to meet the evolving needs of its clients and maintain its standing as a trusted partner in the manufacturing sector.In conclusion, Mould Plastic Injection (MPI) is a premier manufacturer of high-quality plastic injection moulds with a proven track record of excellence and customer satisfaction. With its commitment to quality, innovation, and sustainability, MPI is well-positioned for continued success and growth in the industry.

High-quality Aluminum Fabrication Sheet Metal Parts for Your Project

Aluminum Fabrication Sheet Metal Parts has long been a leading provider of high-quality aluminum fabrication and sheet metal parts for a wide range of industries. With a strong focus on precision and excellence, they have been able to establish themselves as a trusted partner for companies looking for reliable and efficient manufacturing solutions.Their commitment to delivering top-notch products and services has earned them a reputation as a go-to source for custom aluminum fabrication and sheet metal parts. Their state-of-the-art facility, advanced equipment, and skilled workforce enable them to produce components that meet the highest industry standards.The company's extensive experience in aluminum fabrication and sheet metal parts manufacturing allows them to work with clients in a variety of industries, including aerospace, automotive, electronics, and more. Their expertise in CNC machining, welding, and metal finishing ensures that they can deliver components that are not only precise but also durable and aesthetically pleasing.Their dedication to quality and customer satisfaction has made them a preferred partner for many companies seeking tailor-made aluminum fabrication and sheet metal parts. Their ability to understand and meet their clients' specific needs and requirements has helped them build long-lasting relationships and a solid reputation in the industry.In addition to their manufacturing capabilities, Aluminum Fabrication Sheet Metal Parts also offers design and engineering support to help clients optimize their product designs for manufacturability and cost-effectiveness. Their team of experienced engineers can provide valuable insights and recommendations to ensure that the final components meet the desired performance and quality standards.Furthermore, the company's commitment to sustainability and environmental responsibility is evident in their manufacturing processes. They have implemented various initiatives to minimize waste, reduce energy consumption, and ensure that their operations have minimal impact on the environment. As a result, they have been able to align their business practices with the growing demand for eco-friendly manufacturing solutions.Their dedication to excellence and continuous improvement has led them to attain various certifications and accreditations, further validating their commitment to quality and reliability. This includes ISO 9001 certification, which demonstrates their adherence to international quality management standards, as well as various industry-specific certifications that attest to their capability to meet the stringent requirements of different sectors.With their strong track record and unwavering dedication to customer satisfaction, Aluminum Fabrication Sheet Metal Parts continues to be a leading provider of aluminum fabrication and sheet metal parts. Their ability to deliver top-quality components and their commitment to innovation and sustainability set them apart as a trusted and dependable partner for companies seeking superior manufacturing solutions.As they continue to expand their capabilities and enhance their offerings, they remain dedicated to their core values of quality, integrity, and customer focus. By staying at the forefront of technological advancements and industry trends, they are poised to remain a sought-after provider of aluminum fabrication and sheet metal parts for years to come.

High Precision Milling: The Key to Achieving Accurate and Quality Results

High Precision Milling company has been making waves in the industrial sector with its innovative and efficient milling solutions. With a focus on providing high-quality products and exceptional customer service, the company has carved out a niche for itself in the highly competitive market.Founded in [year], High Precision Milling has quickly established itself as a leader in the industry. The company’s dedication to precision and quality has made it a go-to choice for businesses in a wide range of sectors, from aerospace and automotive to medical and electronics.One of the key factors behind High Precision Milling’s success is its state-of-the-art manufacturing facility. The company has invested heavily in cutting-edge machinery and technology, allowing it to produce milling solutions that are truly best-in-class. Whether it’s complex components or large-scale production runs, High Precision Milling has the capabilities to deliver top-notch results every time.In addition to its impressive manufacturing capabilities, the company also prides itself on its team of skilled and experienced professionals. From engineers and technicians to customer service representatives, every member of the High Precision Milling team is committed to upholding the company’s high standards of quality and precision.“Our people are our greatest asset,” says [Name], CEO of High Precision Milling. “We have assembled a team of passionate and talented individuals who are dedicated to pushing the boundaries of what’s possible in the world of milling. Their expertise and commitment are what set us apart from the competition.”Another key differentiator for High Precision Milling is its commitment to continuous improvement. The company is constantly exploring new technologies and techniques to ensure that its products and processes remain at the cutting edge of the industry. This dedication to innovation has allowed High Precision Milling to stay ahead of the curve and consistently deliver exceptional results to its customers.Of course, none of this would matter if High Precision Milling didn’t also prioritize customer satisfaction. The company has built a strong reputation for its reliability, responsiveness, and willingness to go the extra mile to meet its customers’ needs. From initial consultations to ongoing support, High Precision Milling is committed to providing an exceptional experience at every step of the way.“Our customers put their trust in us to deliver reliable, high-quality milling solutions, and we take that responsibility very seriously,” says [Name]. “We work closely with each of our customers to understand their unique needs and provide tailored solutions that meet and exceed their expectations. Our goal is to build long-lasting partnerships based on mutual trust and respect.”Looking to the future, High Precision Milling is poised for continued success and growth. The company has ambitious plans to expand its operations and reach new markets, both domestically and internationally. By staying true to its core values of quality, innovation, and customer focus, High Precision Milling is well positioned to remain a leader in the industry for years to come.In conclusion, High Precision Milling has proven itself to be a force to be reckoned with in the world of industrial milling. With its relentless commitment to quality and innovation, the company has earned a reputation as a trusted partner for businesses in a wide range of sectors. As it continues to grow and evolve, High Precision Milling is poised to cement its position as a leader in the industry for many years to come.

High Precision CNC Machining Services for Your Business Needs

CNC Precision Manufacturing Company Leads the Industry with State-of-the-Art TechnologyIn the fast-paced world of manufacturing, precision is paramount. From small components to large-scale productions, precision in manufacturing is the key to success. This is where CNC Precision Manufacturing Company has set itself apart from the competition. With their cutting-edge technology and commitment to excellence, they have become a leading force in the industry.CNC Precision Manufacturing Company, based in (location), has been at the forefront of the manufacturing industry for over 20 years. Specializing in precision machining and fabrication, the company has built a reputation for delivering top-quality products to a wide range of industries, including aerospace, automotive, medical, and defense.The company's success can be attributed to its state-of-the-art facility, which is fully equipped with the latest CNC machines, robotic arms, and advanced software. This allows the team of highly skilled engineers and technicians to produce components with unparalleled accuracy and efficiency. The company's dedication to investing in cutting-edge technology has allowed them to stay ahead of the curve and meet the ever-changing demands of the market.One of the key factors that has set CNC Precision Manufacturing Company apart from its competitors is its commitment to innovation. The company constantly seeks new ways to improve its processes and enhance its capabilities. By investing in research and development, the company has been able to develop innovative solutions that have revolutionized the manufacturing process. This has allowed them to produce complex components with intricate designs and tight tolerances, giving them an edge in the market.Furthermore, CNC Precision Manufacturing Company has a strong emphasis on quality control. Every component goes through a rigorous inspection process to ensure that it meets the highest standards. This dedication to quality has earned the company numerous certifications and accolades, making it a trusted partner for companies that demand precision and reliability in their components.In addition to its technical capabilities, CNC Precision Manufacturing Company places a significant emphasis on customer satisfaction. The team works closely with its clients to understand their specific needs and requirements, offering personalized solutions that meet and exceed their expectations. This customer-centric approach has solidified the company's reputation as a reliable and trusted partner in the industry.CNC Precision Manufacturing Company's commitment to excellence has not gone unnoticed. The company has received numerous awards and recognition for its outstanding performance and contributions to the industry. With a strong track record of delivering exceptional products and services, the company continues to be a leading force in the manufacturing sector.Looking ahead, CNC Precision Manufacturing Company remains dedicated to pushing the boundaries of innovation in manufacturing. With a focus on continuous improvement and a forward-thinking approach, the company is poised to continue setting new standards in precision machining and fabrication. As the industry continues to evolve, CNC Precision Manufacturing Company is committed to staying at the forefront of technological advancements and delivering superior products that meet the demands of the modern manufacturing landscape.For companies that demand the highest level of precision and quality in their components, CNC Precision Manufacturing Company stands ready to deliver. With its cutting-edge technology, commitment to innovation, and dedication to customer satisfaction, the company is poised to lead the industry for years to come.