Machined Custom PTFE Parts for Various Applications

By:Admin

Custom PTFE (polytetrafluoroethylene) parts are in high demand across various industries due to their excellent chemical resistance, low friction, and high temperature performance. Companies are constantly in search of reliable manufacturers who can deliver precision machined PTFE parts that meet their specific requirements. One such company that has been making waves in the industry is [Company Name].

[Company Name] is a leading manufacturer of custom PTFE parts, offering a wide range of machining capabilities to cater to the diverse needs of its customers. With a commitment to quality and precision, the company has established itself as a trusted partner for businesses looking for high-performance PTFE components.

The company's state-of-the-art facility is equipped with advanced CNC machines and other cutting-edge technologies that enable it to deliver custom PTFE parts with tight tolerances and intricate geometries. From simple PTFE bushings to complex PTFE seals and gaskets, [Company Name] has the expertise and capabilities to machine a wide variety of PTFE parts to perfection.

One of the key advantages of working with [Company Name] is its team of highly skilled engineers and technicians who have extensive experience in working with PTFE materials. They work closely with customers to understand their unique requirements and provide expert guidance to optimize the design and manufacturing processes, ensuring that the final parts meet the highest standards of quality and performance.

In addition to its machining capabilities, [Company Name] also offers a range of secondary services such as precision welding, surface treatments, and custom packaging to provide a comprehensive solution for its customers' PTFE component needs. This end-to-end service approach has earned the company a reputation for delivering exceptional value and customer satisfaction.

Recently, [Company Name] made significant investments in its infrastructure and capabilities to further enhance its machining capacity and efficiency. This includes the acquisition of new equipment and tools, as well as the implementation of advanced process controls to improve the overall quality and consistency of its custom PTFE parts.

Furthermore, [Company Name] has also expanded its material options to include filled PTFE grades, such as glass-filled and carbon-filled PTFE, to meet the growing demand for specialized PTFE parts with enhanced mechanical properties. This strategic move has allowed the company to address a wider range of applications and industries, from automotive and aerospace to medical and chemical processing.

The commitment to continuous improvement and innovation has positioned [Company Name] as a preferred supplier of custom PTFE parts for both small-scale businesses and large corporations. The company's dedication to meeting and exceeding customer expectations has resulted in numerous long-term partnerships and repeat business, testifying to the quality and reliability of its products and services.

With a strong focus on precision, quality, and customer satisfaction, [Company Name] has demonstrated its ability to deliver custom PTFE parts machined to perfection. As the demand for high-performance PTFE components continues to grow, [Company Name] is well-positioned to uphold its reputation as a trusted industry leader in the machining of custom PTFE parts.

Company News & Blog

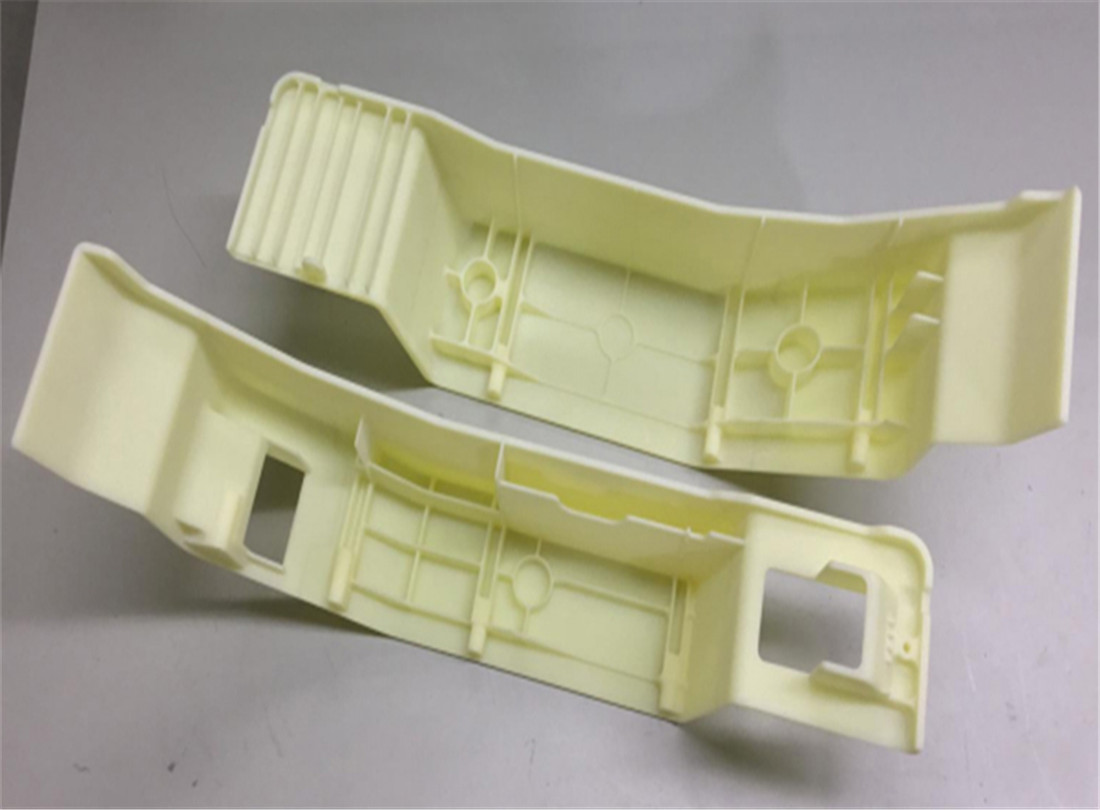

Exploring the Benefits of Rapid Prototyping in Product Development

Rapid Prototype Revolutionizing Manufacturing ProcessesIn today's fast-paced world, the demand for speedy and efficient manufacturing processes is at an all-time high. This is where Rapid Prototype comes into play, offering innovative solutions that are revolutionizing the way companies design and develop products.Rapid Prototype specializes in providing cutting-edge prototyping services to a wide range of industries, including automotive, aerospace, medical, and consumer goods. With a team of experienced engineers and state-of-the-art technology, Rapid Prototype has earned a reputation for delivering high-quality prototypes in record time.One of the key factors that sets Rapid Prototype apart is its commitment to using the latest 3D printing technology. This allows the company to create prototypes with incredible precision and detail, giving clients a realistic representation of their final product. By leveraging 3D printing, Rapid Prototype is able to drastically reduce the time and cost associated with traditional prototyping methods, providing clients with a competitive edge in their respective industries.Furthermore, Rapid Prototype offers a wide range of materials for prototyping, including plastics, metals, and composites, ensuring that their clients can test and evaluate different designs and materials before committing to mass production. This flexibility is crucial in helping companies refine their products and ensure that they meet the highest standards of quality and performance.In addition to its prototyping services, Rapid Prototype also offers design and engineering support to help clients bring their ideas to life. The company's team of experts works closely with clients to understand their requirements and provide valuable insights and recommendations throughout the prototyping process. This collaborative approach has allowed Rapid Prototype to build long-lasting partnerships with leading companies in various industries.One such success story involves a leading automotive manufacturer that turned to Rapid Prototype for assistance in developing a new car part. The manufacturer was facing significant challenges in prototyping the complex component, and Rapid Prototype was able to deliver a fully functional prototype within a matter of days. This accelerated timeline allowed the manufacturer to test the part in real-world conditions and make necessary design adjustments before moving into mass production, ultimately saving them time and money.Rapid Prototype's commitment to innovation and customer satisfaction has led to its rapid growth and expansion in recent years. The company has continued to invest in the latest technologies and equipment to further improve its prototyping capabilities, ensuring that its clients have access to the best resources available.Looking ahead, Rapid Prototype is poised to continue its trajectory of success, with plans to further expand its services and reach new markets. The company's dedication to pushing the boundaries of prototyping and manufacturing is not only benefiting its clients, but also contributing to the overall advancement of the industry.In conclusion, Rapid Prototype's commitment to excellence and innovation has cemented its position as a leader in the prototyping industry. By leveraging cutting-edge 3D printing technology, offering a diverse range of materials, and providing expert engineering support, Rapid Prototype is empowering companies to bring their ideas to life with unprecedented speed and efficiency. As the demand for rapid prototyping continues to grow, Rapid Prototype is well-positioned to remain at the forefront of this transformative industry.

High-Quality Aluminum Die Casting Services for Various Industries

Aluminum Die Casting: A Game-Changer in the Manufacturing IndustryIn today's highly competitive manufacturing industry, companies are constantly seeking ways to improve efficiency, reduce costs, and enhance the overall quality of their products. One of the key technologies that has been making a significant impact in this regard is aluminum die casting. Featured as an integral part of the company’s manufacturing process, aluminum die casting has revolutionized the way products are made. With its ability to produce complex and intricately shaped parts with high precision, aluminum die casting has become the go-to method for many industries, including automotive, aerospace, and electronics.At the forefront of this industry-leading technology is {Company Name}, a renowned company with a sterling reputation for excellence in the field of aluminum die casting. With state-of-the-art facilities and a team of highly skilled professionals, {Company Name} has been leading the way in delivering high-quality aluminum die casting solutions to its clients.Aluminum die casting is a process that involves injecting molten aluminum into a steel mold, known as a die, at high pressures. This results in the production of parts that are extremely durable, with excellent mechanical properties and low porosity. The versatility of this process allows for the production of a wide range of complex shapes and sizes, making it an ideal choice for a variety of applications.One of the key advantages of aluminum die casting is its cost-effectiveness. The high-speed production capabilities and the ability to produce net-shaped parts with minimal secondary operations make it a highly efficient manufacturing process. This, in turn, leads to significant cost savings for companies, ultimately translating to a competitive edge in the market.Furthermore, the lightweight nature of aluminum makes it an ideal material for applications in industries such as automotive and aerospace, where weight reduction is a critical factor. Aluminum die cast parts offer high strength-to-weight ratios, making them an excellent choice for demanding applications that require both strength and durability.{Company Name} has been at the forefront of innovation in aluminum die casting, constantly pushing the boundaries of what is possible in terms of part complexity, precision, and quality. Their extensive experience in the industry, combined with their commitment to continuous improvement, has enabled them to consistently deliver exceptional results to their clients.The company's dedication to quality is reflected in their stringent quality control measures and adherence to industry standards. By utilizing advanced simulation and testing techniques, {Company Name} ensures that each part produced through aluminum die casting meets the highest standards of quality and performance.In addition to aluminum die casting, {Company Name} also offers a range of value-added services, including machining, finishing, and assembly. This comprehensive approach allows them to provide end-to-end solutions to their clients, further cementing their position as a trusted partner in the manufacturing industry.With the ever-increasing demand for high-quality, precision-engineered parts, the future of aluminum die casting looks brighter than ever. {Company Name} remains committed to staying at the forefront of this industry, continuously investing in the latest technologies and processes to meet the evolving needs of their clients.In conclusion, aluminum die casting has undoubtedly emerged as a game-changer in the manufacturing industry, and {Company Name} is leading the charge with its unparalleled expertise and dedication to excellence. As the industry continues to evolve, {Company Name} remains poised to deliver innovative solutions that will shape the future of manufacturing for years to come.

High-Quality Turned Components for Various Applications

Turned Components, a leading manufacturer of precision-engineered components, has recently announced the launch of its new range of high-quality turned components for the automotive industry. These components have been designed to meet the increasing demands for efficiency, reliability, and performance in modern vehicles.With over 20 years of experience in the industry, Turned Components has become a trusted name in the manufacturing of precision-engineered components. The company specializes in producing a wide range of turned components such as shafts, pins, bushings, and fasteners for diverse applications, including automotive, aerospace, medical, and industrial equipment.The new range of turned components for the automotive industry has been developed to address the growing need for high-quality, reliable parts that can withstand the demanding conditions of modern vehicles. These components are manufactured using the latest CNC turning technology and are made from premium-grade materials to ensure durability and performance.One of the key features of the new range of turned components is their precision engineering, which allows for tight tolerances and accurate dimensions. This ensures that the components fit seamlessly into the overall assembly of the vehicle, resulting in improved performance and reduced maintenance requirements.Furthermore, Turned Components has implemented stringent quality control measures to ensure that all components meet the highest industry standards. Each component undergoes rigorous testing and inspection processes to guarantee its reliability and durability, allowing customers to have confidence in the products they receive.In addition to the new range of turned components, Turned Components also offers custom manufacturing services to meet the specific requirements of its customers. The company's team of experienced engineers and technicians work closely with customers to develop tailored solutions that meet their unique needs and specifications.Turned Components takes pride in its ability to deliver precision-engineered components that are not only of the highest quality but also cost-effective. The company's commitment to innovation and continuous improvement has allowed it to stay at the forefront of the industry, providing customers with cutting-edge solutions that exceed their expectations.With the launch of the new range of turned components for the automotive industry, Turned Components aims to further solidify its position as a leading supplier of precision-engineered components. The company is dedicated to meeting the evolving needs of its customers and is focused on developing new and innovative solutions to address the challenges of the automotive industry.As the demand for high-quality turned components continues to grow, Turned Components is well-positioned to meet the needs of its customers with its extensive experience, state-of-the-art manufacturing facilities, and commitment to excellence.In conclusion, Turned Components has established itself as a reliable and trusted manufacturer of precision-engineered components, and the launch of its new range of turned components for the automotive industry is a testament to its commitment to innovation and quality. With its dedication to meeting the evolving needs of its customers and its focus on delivering high-quality solutions, Turned Components is poised to remain a leader in the industry for years to come.

Stamped Sheet Metal Parts: Benefits, Uses, and Applications

[Company Introduction]: Based in [Location], [Company Name] is a leading manufacturer of precision stamped sheet metal parts for a wide range of industries. With over [number] years of experience in the industry, the company is known for its high-quality products, advanced manufacturing techniques, and commitment to customer satisfaction. [Company Name] offers a comprehensive range of stamped sheet metal parts, including brackets, clips, enclosures, and more. The company's state-of-the-art facilities and skilled team allow them to meet the unique needs of their customers, providing custom solutions and quick turnaround times.[News Content]:Stamped Sheet Metal Parts: Enhancing Manufacturing EfficiencyIn today's fast-paced and demanding manufacturing industry, precision and efficiency are key factors in ensuring success. As a leading manufacturer of stamped sheet metal parts, [Company Name] plays a crucial role in helping companies across various industries enhance their manufacturing processes.Stamped sheet metal parts are integral components used in a wide array of products, from automotive parts to electronic devices. They are essential for ensuring the structural integrity, durability, and functionality of these products. With its expertise and cutting-edge manufacturing capabilities, [Company Name] has established itself as a trusted partner for businesses looking to source high-quality stamped sheet metal parts.One of the key strengths of [Company Name] is its ability to provide custom solutions to meet the specific needs of its clients. By leveraging advanced manufacturing techniques and the latest technology, the company is able to produce stamped sheet metal parts with unparalleled precision and consistency. Whether it's a unique design requirement or a tight production deadline, [Company Name] is equipped to deliver top-notch solutions that meet and exceed customer expectations.Furthermore, [Company Name] prides itself on its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of industry trends and technological advancements. This proactive approach allows [Company Name] to offer its clients the latest advancements in stamped sheet metal parts, ensuring that they benefit from the most efficient and cost-effective solutions.In addition to its technical prowess, [Company Name] places a strong emphasis on customer satisfaction. The company's team of skilled professionals works closely with clients to understand their unique requirements and provide tailored solutions. From the initial design phase to the final delivery of the stamped sheet metal parts, [Company Name] maintains open lines of communication and a transparent approach, ensuring that customers are fully satisfied with the end product.As the manufacturing industry continues to evolve, the demand for high-quality stamped sheet metal parts is expected to grow. With its proven track record of excellence, [Company Name] is well-positioned to meet this growing demand and provide industry-leading solutions to its clients.In conclusion, stamped sheet metal parts are integral to the manufacturing process, and [Company Name] is at the forefront of delivering high-quality, custom solutions to meet the needs of various industries. With its commitment to innovation, precision, and customer satisfaction, [Company Name] is poised to continue playing a pivotal role in enhancing manufacturing efficiency for years to come.

High-Quality Elastomer Injection Molding: Benefits and Applications

Elastomer Injection Molding is a crucial process in the manufacturing industry, and it is increasingly becoming popular due to its efficiency and effectiveness in producing high-quality elastomer products. One of the leading companies at the forefront of Elastomer Injection Molding is {Company Name}.{Company Name} is a renowned manufacturer of elastomer products, and their expertise in Elastomer Injection Molding has made them a trusted partner for various industries, including automotive, aerospace, medical, and consumer goods. With their state-of-the-art facilities and cutting-edge technology, {Company Name} has been able to meet the diverse needs of their clients and deliver top-notch elastomer products that meet the highest industry standards.Elastomer Injection Molding is a process that involves injecting molten elastomer material into a mold cavity, where it is then allowed to cool and solidify, taking the shape of the mold. This process allows for the production of complex and intricate elastomer products with high precision and consistency. {Company Name} has mastered this process, and their expertise in Elastomer Injection Molding has enabled them to deliver a wide range of products, including seals, gaskets, O-rings, and custom-molded elastomer parts.One of the key advantages of Elastomer Injection Molding is its ability to produce elastomer products with excellent dimensional stability and tight tolerances. This is essential in industries such as automotive and aerospace, where precision and reliability are paramount. {Company Name} has leveraged their expertise in Elastomer Injection Molding to meet the stringent requirements of these industries, producing elastomer products that can withstand extreme temperatures, pressures, and environmental conditions.Furthermore, Elastomer Injection Molding allows for the use of a wide variety of elastomer materials, including silicone, fluorocarbon, nitrile, and EPDM. {Company Name} has a thorough understanding of these materials and their properties, allowing them to recommend the most suitable elastomer material for each specific application. Whether it's for sealing, cushioning, or dampening, {Company Name} can provide elastomer products that meet the desired performance and functionality requirements.In addition to their expertise in Elastomer Injection Molding, {Company Name} also prides itself on its commitment to quality and customer satisfaction. Their ISO-certified quality management system ensures that every elastomer product that leaves their facility meets the highest quality standards. From the initial design and engineering phase to the final inspection and testing, {Company Name} maintains a rigorous quality control process to ensure that their products exceed customer expectations.Moreover, {Company Name} is dedicated to staying at the forefront of innovation in Elastomer Injection Molding. They continuously invest in research and development, as well as in the latest manufacturing technologies, to improve their processes and expand their capabilities. This commitment to innovation has enabled {Company Name} to take on complex elastomer molding projects and deliver solutions that push the boundaries of what is possible with elastomer materials.As the demand for high-performance elastomer products continues to grow across various industries, {Company Name} remains a reliable and trusted partner for companies seeking top-quality elastomer solutions. Their expertise in Elastomer Injection Molding, combined with their dedication to quality and innovation, positions them as a leading manufacturer in the elastomer industry.In conclusion, {Company Name} is a company with a proven track record of excellence in Elastomer Injection Molding. Their commitment to quality, innovation, and customer satisfaction sets them apart as a trusted partner for companies seeking high-quality elastomer products. With their expertise and state-of-the-art facilities, {Company Name} continues to drive the advancement of elastomer technology and provide solutions that meet the evolving needs of the manufacturing industry.

Precision CNC Machining for Aerospace Parts: A Complete Guide

In the world of aerospace manufacturing, precision and quality are of utmost importance. As the demand for aerospace parts continues to grow, companies are constantly seeking ways to improve their machining processes to meet the high standards required for aerospace components. The use of CNC machining has become increasingly popular in the aerospace industry due to its ability to produce high precision parts with tight tolerances. One company at the forefront of this technology is {Company Name}.{Company Name} has been a leading provider of CNC machining services for aerospace parts for over a decade. With a commitment to quality and excellence, the company has established itself as a reliable partner for aerospace manufacturers around the world. Specializing in the production of complex and intricate components, {Company Name} has the expertise and capabilities to meet the demands of the aerospace industry.Utilizing state-of-the-art CNC machining equipment, {Company Name} is able to manufacture a wide range of aerospace parts, including engine components, landing gear parts, and structural components. The company's team of highly skilled machinists and engineers work closely with clients to understand their specific requirements and develop tailored solutions to meet their needs. Whether it's a single prototype or a large production run, {Company Name} has the capabilities to deliver high-quality aerospace parts on time and within budget.One of the key advantages of CNC machining is its ability to produce parts with incredibly tight tolerances. This is crucial in the aerospace industry, where components need to meet strict specifications to ensure safety and reliability. {Company Name}'s state-of-the-art CNC machines are capable of achieving precision of up to 0.001mm, allowing for the production of extremely accurate and consistent parts. This level of precision is essential for aerospace components that are subjected to extreme conditions and high stress levels.In addition to precision, CNC machining also offers versatility in the types of materials that can be used. {Company Name} has the capabilities to machine a wide range of aerospace-grade materials, including aluminum, titanium, stainless steel, and various high-performance alloys. This flexibility allows the company to cater to the diverse needs of aerospace manufacturers and produce a wide variety of components for different applications.Furthermore, {Company Name} places a strong emphasis on quality control throughout the machining process. The company utilizes advanced inspection equipment and techniques to ensure that every part meets the highest standards of accuracy and quality. From initial design to final inspection, {Company Name} is committed to delivering aerospace parts that meet or exceed the stringent requirements of the industry.As the aerospace industry continues to evolve and demand for high-quality parts grows, {Company Name} remains dedicated to staying at the forefront of CNC machining technology. The company regularly invests in the latest CNC machines and software to enhance its capabilities and offer innovative solutions to its clients. By combining cutting-edge technology with a team of experienced professionals, {Company Name} is well-positioned to meet the evolving needs of the aerospace industry and continue to be a trusted partner for aerospace manufacturers.In conclusion, {Company Name} is a leading provider of CNC machining services for aerospace parts, offering a combination of precision, quality, and versatility to meet the demands of the aerospace industry. With a focus on innovation and continuous improvement, the company is well-equipped to tackle the challenges of modern aerospace manufacturing and deliver reliable solutions to its clients. With a dedication to excellence and a commitment to customer satisfaction, {Company Name} is poised to remain a key player in the aerospace machining industry for years to come.

Top Techniques for Sheet Metal Bending

[Company Name] is a leading provider of sheet metal bending solutions for a wide range of industries. The company has established a strong reputation for its expertise in precision bending and forming of sheet metal, using advanced technologies and state-of-the-art machinery to deliver high-quality products to its customers.Sheet metal bending is a critical process in the manufacturing of various products, ranging from automotive components and aerospace parts to household appliances and electronic devices. It involves the deformation of a metal sheet into a desired shape or form by applying force through a press brake or other bending equipment. Precision and accuracy are essential in sheet metal bending to ensure that the final product meets the required specifications and standards.With years of experience and technical know-how, [Company Name] has developed a comprehensive range of sheet metal bending capabilities to cater to diverse customer needs. The company's team of skilled engineers and technicians work closely with clients to understand their specific requirements and provide tailored solutions that meet their expectations.One of the key strengths of [Company Name] is its investment in advanced bending machinery and equipment. The company utilizes cutting-edge press brakes with computer numerical control (CNC) technology, which enables precise control of the bending process and the ability to produce complex shapes with high accuracy. This capability allows [Company Name] to handle a wide variety of metal materials, including aluminum, steel, stainless steel, and titanium, among others, in varying thicknesses.In addition to its technical expertise, [Company Name] places a strong emphasis on quality and efficiency in its sheet metal bending operations. The company adheres to strict quality control measures throughout the production process, ensuring that every bent component meets the highest standards of precision and consistency. By implementing lean manufacturing principles and optimizing its workflows, [Company Name] is able to deliver cost-effective solutions without compromising on quality.Furthermore, [Company Name] is committed to staying at the forefront of industry developments and innovation in sheet metal bending. The company continuously invests in research and development to explore new techniques, materials, and technologies that can further enhance its bending capabilities and offer added value to its customers. By staying ahead of the curve, [Company Name] is able to meet the evolving needs of the market and provide cutting-edge solutions for challenging bending applications.As a reliable partner for sheet metal bending, [Company Name] serves a diverse customer base across various industries, including automotive, aerospace, electronics, and manufacturing. The company's ability to handle both small-scale and large-scale production runs makes it a preferred choice for businesses seeking high-quality and cost-effective bending solutions.In conclusion, [Company Name] continues to set the standard for excellence in sheet metal bending, driven by its commitment to precision, quality, and innovation. With its extensive capabilities, state-of-the-art machinery, and dedicated team, the company is well-positioned to meet the complex bending needs of today's manufacturing landscape and deliver value-added solutions to its customers.For more information about [Company Name] and its sheet metal bending services, please visit [company website] or contact the company directly at [contact information].

Guide to Precision Plastic Molding: Everything You Need to Know

Precision Plastic Molding, a leading manufacturer of plastic components, has been making waves in the industry with their commitment to delivering high-quality and innovative products. With a strong focus on precision and customization, the company has established itself as a trusted partner for businesses across various sectors.Established in 2005, Precision Plastic Molding has steadily grown to become a key player in the plastic molding industry. Their state-of-the-art facility, equipped with the latest technology and machinery, allows them to offer a wide range of plastic molding services, including injection molding, blow molding, and rotational molding. This versatility enables them to cater to the diverse needs of their clients, producing everything from small, intricate components to large, complex parts.One of the key strengths of Precision Plastic Molding lies in their ability to work closely with their clients to understand their specific requirements. With a team of experienced engineers and designers, the company is able to provide customized solutions that meet the exact specifications of each project. This collaborative approach ensures that clients receive products that not only meet their expectations but also exceed industry standards.Furthermore, Precision Plastic Molding is committed to upholding the highest standards of quality in every aspect of their operations. From the selection of materials to the manufacturing process, the company adheres to stringent quality control measures to ensure that each product meets their rigorous quality standards. This dedication to quality has earned them a reputation for reliability and consistency, making them a preferred choice for businesses seeking top-notch plastic molding solutions.In addition to their commitment to quality, Precision Plastic Molding places a strong emphasis on innovation and continuous improvement. By staying abreast of the latest technological advancements and industry trends, the company is able to offer cutting-edge solutions that are at the forefront of plastic molding technology. This proactive approach not only allows them to meet the evolving needs of their clients but also positions them as an industry leader in innovation.Moreover, Precision Plastic Molding is dedicated to sustainability and eco-friendly practices. They have implemented environmentally conscious initiatives throughout their operations, including the use of recyclable materials and energy-efficient manufacturing processes. By prioritizing sustainability, the company not only reduces its environmental impact but also provides clients with sustainable solutions that align with their corporate responsibility goals.As a result of their unwavering commitment to excellence, Precision Plastic Molding has garnered a loyal client base comprising businesses from diverse sectors, including automotive, consumer goods, electronics, and healthcare. The company's track record of delivering superior products and exceptional customer service has earned them the trust and confidence of their clients, many of whom have continued to rely on their expertise for their plastic molding needs.Looking ahead, Precision Plastic Molding is poised to continue its trajectory of success, driven by its dedication to quality, innovation, and customer satisfaction. With a strong foundation built on expertise and reliability, the company is well-positioned to capitalize on new opportunities and expand its presence in the plastic molding industry. As a trusted partner for businesses seeking top-tier plastic molding solutions, Precision Plastic Molding is set to remain at the forefront of the industry, setting new benchmarks for excellence.

New fully functional prototype unveiled

Fully Functional Prototype Unveiled by Renowned CompanyThe renowned company, known for its innovative and cutting-edge technological advancements, has recently unveiled its latest creation - a fully functional prototype that has the potential to revolutionize the industry. This prototype represents a significant milestone for the company, as it showcases their commitment to pushing the boundaries of what is possible in the world of technology.The prototype, which has been in development for several years, is the result of the company's relentless pursuit of innovation and excellence. It represents the culmination of countless hours of research, development, and testing, and is a testament to the company's dedication to staying at the forefront of technological advancements.The prototype boasts a range of groundbreaking features that set it apart from anything else on the market. It is equipped with state-of-the-art technology that enables it to perform tasks with unprecedented efficiency and accuracy. In addition, it incorporates advanced materials and design elements that make it not only highly functional but also visually striking.One of the most impressive aspects of the prototype is its versatility. It has been designed to be adaptable to a wide range of applications, making it suitable for use in various industries. From manufacturing and construction to healthcare and transportation, the prototype has the potential to revolutionize the way that tasks are carried out in numerous fields.The unveiling of the fully functional prototype has generated significant excitement within the industry, with experts and enthusiasts alike eagerly anticipating its potential impact. Many are already speculating about the ways in which this prototype could be integrated into existing technologies and processes, and the possibilities seem endless.The company behind the prototype is no stranger to pushing the boundaries of what is possible in the world of technology. With a long history of groundbreaking innovations and a track record of success, they have earned a reputation as a leader in the industry. Their commitment to excellence and their ability to think outside the box have consistently set them apart from their peers, and the unveiling of this prototype only serves to reinforce their position at the forefront of technological advancements.In addition to its impressive technological achievements, the company is also known for its dedication to sustainability and social responsibility. They have made significant investments in developing technologies that minimize environmental impact and improve the lives of individuals and communities around the world. This commitment to making a positive difference sets them apart as a company that is not only focused on profits, but also on making the world a better place.As the fully functional prototype continues to generate excitement and speculation, the company remains focused on the next steps in its development. They are committed to refining and perfecting the prototype, with the goal of bringing it to market in the near future. In the meantime, they continue to explore new opportunities for collaboration and partnership, recognizing that the potential impact of this prototype extends far beyond their own capabilities.Overall, the unveiling of the fully functional prototype represents a significant achievement for the company and a defining moment in the world of technology. With its groundbreaking features, adaptability, and potential for revolutionizing multiple industries, it is clear that this prototype has the power to change the way we think about technology. As the company continues to push the boundaries of what is possible, the world eagerly awaits the next chapter in this exciting technological journey.

Top Rapid Prototype Machining Services for Your Business Needs

Rapid Prototype Machining has become an integral part of the manufacturing industry in recent years, allowing companies to quickly and cost-effectively produce prototypes and final products. With the advancement of technology and the rise of 3D printing, rapid prototype machining has become even more efficient and accessible.[Company Name] is a leading provider of rapid prototype machining services, offering a wide range of capabilities to support the diverse needs of their clients. With a team of experienced engineers and state-of-the-art equipment, [Company Name] has established itself as a reliable partner for companies across various industries, including automotive, aerospace, medical, and consumer goods.The company's extensive machining capabilities include CNC milling, turning, grinding, and EDM, allowing them to produce high-quality prototypes and production parts with precision and accuracy. In addition to their machining services, [Company Name] also offers 3D printing and additive manufacturing solutions, further expanding their ability to meet the dynamic needs of their clients.One of the key advantages of rapid prototype machining is the ability to quickly iterate and test designs, reducing time to market and ultimately saving costs. This is especially beneficial for companies looking to innovate and bring new products to market faster. By leveraging [Company Name]'s rapid prototype machining services, clients can accelerate their product development process and gain a competitive edge in their respective markets.Furthermore, [Company Name] takes pride in its ability to work closely with clients throughout the entire production process. From initial concept development to final production, the company's team of engineers and machinists collaborate with clients to ensure that their vision is realized with the highest quality standards in mind.In a recent interview, [Company Name]'s CEO commented on the company's commitment to providing exceptional rapid prototype machining services. "We understand the importance of speed and accuracy in the prototyping and production process," he said. "Our goal is to empower our clients with the tools and resources they need to bring their ideas to life, and we are dedicated to delivering the best possible results."As the manufacturing industry continues to evolve, rapid prototype machining will undoubtedly play a crucial role in shaping the future of production. With [Company Name]'s advanced capabilities and commitment to excellence, they are positioned to remain at the forefront of this exciting and dynamic industry.In conclusion, rapid prototype machining has revolutionized the way companies develop and produce new products, and [Company Name] has emerged as a trusted partner for those seeking high-quality machining services. With a focus on innovation, precision, and customer satisfaction, [Company Name] is well-equipped to meet the evolving needs of its clients and make a lasting impact in the manufacturing industry.