Fast and Efficient CNC Machining Rapid Prototyping Services for Your Business

By:Admin

One company that has been at the forefront of CNC machining rapid prototyping is {}. Their commitment to innovation and excellence has made them a leader in the industry, providing high-quality prototype and production parts to a wide range of industries, including aerospace, automotive, medical, and consumer goods.

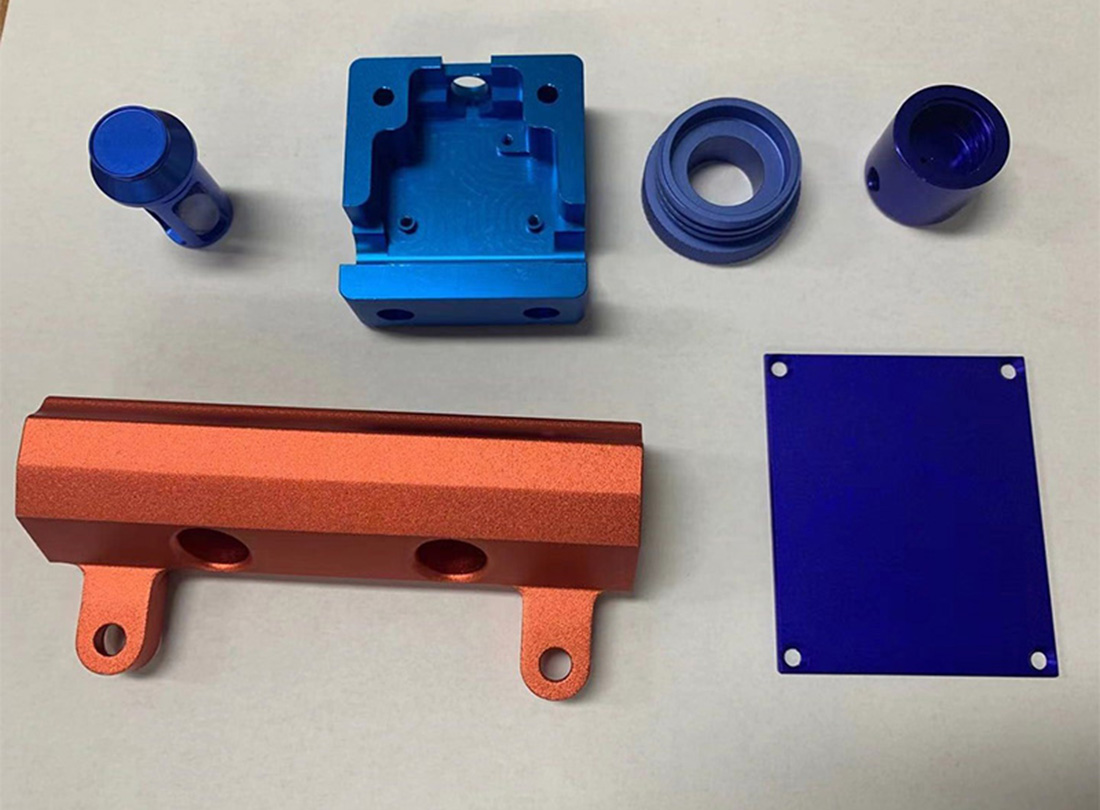

CNC machining rapid prototyping is a process that uses computer-controlled machines to produce a prototype or production part from a digital 3D model. This process allows for highly accurate and precise results, with the ability to produce complex geometries and intricate designs. With the use of advanced CNC machines, {} is able to produce prototypes and production parts with tight tolerances, smooth surface finishes, and quick turnaround times.

One of the key benefits of CNC machining rapid prototyping is its ability to produce a wide range of materials, including metals, plastics, and composites. This versatility allows companies to test their designs with different materials and make necessary adjustments before moving into full production. With the expertise and advanced capabilities of {}, companies can rely on their prototypes to accurately represent the final product, ensuring that it meets both design and performance requirements.

In addition to prototyping, CNC machining rapid prototyping can also be used for low-volume production parts. This is especially beneficial for companies looking to quickly ramp up production or test the market before investing in full-scale manufacturing. {}'s state-of-the-art facilities and skilled engineers can efficiently produce low-volume production parts with the same level of quality and precision as prototypes, allowing companies to bring their products to market faster and more cost-effectively.

As market demands continue to evolve, {} constantly invests in the latest technology and equipment to stay ahead of the curve. Their continuous improvement in CNC machining rapid prototyping has allowed them to offer a wide range of services to meet the diverse needs of their clients. From design assistance and material selection to precision machining and quality inspection, {} provides comprehensive solutions to support their clients' product development and manufacturing processes.

Furthermore, {} places a strong emphasis on quality and customer satisfaction, ensuring that every part produced meets or exceeds industry standards. Their commitment to quality is evident in their ISO 9001 certification, demonstrating their dedication to delivering exceptional products and services to their clients. This focus on quality has earned them a reputation as a trusted partner in the industry, with many satisfied clients returning for their CNC machining rapid prototyping needs.

In conclusion, CNC machining rapid prototyping is a critical component of the product development and manufacturing process, and {}'s expertise and advanced capabilities have positioned them as a leader in the industry. Their commitment to innovation, quality, and customer satisfaction sets them apart, making them the go-to partner for companies seeking high-quality prototypes and production parts. As technology continues to advance, {} will continue to push the boundaries of CNC machining rapid prototyping, providing their clients with cutting-edge solutions to bring their products to market faster and more efficiently.

Company News & Blog

Benefits of Small Run Injection Molding for Manufacturing

Small Run Injection Molding (SRI) is a leading manufacturing company specialized in providing high-quality plastic injection molding solutions for small to medium-sized production runs. With a strong focus on quality, precision, and customer satisfaction, SRI has established a solid reputation in the industry for delivering exceptional products to various clients across different sectors.Established over a decade ago, SRI has continuously evolved and expanded its capabilities to meet the ever-growing demands of the market. The company’s state-of-the-art manufacturing facility is equipped with advanced injection molding machines, cutting-edge technologies, and a team of highly skilled professionals who are dedicated to delivering outstanding results. As a full-service provider, SRI offers a comprehensive range of services including product design, tooling, prototyping, and production.SRI takes pride in its ability to cater to the unique needs of its clients, offering flexible solutions that are tailored to their specific requirements. Whether it’s a small batch of custom-designed parts or a medium-sized production run, the company is committed to delivering superior quality products with a quick turnaround time. SRI's expertise in small run injection molding allows businesses to bring their concepts to life and get their products to market in a cost-effective and efficient manner.One of the key differentiators for SRI is its dedication to maintaining the highest standards of quality throughout the production process. The company follows strict quality control protocols to ensure that every product that comes out of its facility meets the exacting specifications of its clients. This commitment to quality has earned SRI the trust and loyalty of its customers, who rely on the company for consistent, reliable, and top-notch results.Additionally, SRI places a strong emphasis on innovation and continuous improvement. The company stays abreast of the latest advancements in injection molding technology and regularly invests in upgrading its infrastructure to stay ahead of the curve. This proactive approach enables SRI to take on challenging projects, push the boundaries of what is possible in injection molding, and deliver innovative solutions to its clients.In line with its commitment to sustainability, SRI also places a high priority on environmental responsibility. The company utilizes eco-friendly materials and processes wherever possible, minimizing its ecological footprint while still delivering high-quality products. By adopting sustainable practices, SRI is contributing to a more environmentally conscious approach to manufacturing.SRI has earned recognition for its excellence in manufacturing and has received accolades for its exceptional performance, reliability, and customer satisfaction. The company's dedication to its craft and its unwavering commitment to exceeding customer expectations have positioned it as a trusted partner for businesses seeking top-tier injection molding solutions.Overall, Small Run Injection Molding (SRI) stands out as a prime example of a manufacturing company that excels in delivering high-quality, precision-engineered products for small to medium-sized production runs. With its focus on innovation, quality, and customer satisfaction, SRI continues to solidify its position as a leader in the injection molding industry, setting new benchmarks for excellence and reliability. Whether it's a custom project or a standard production run, SRI is the go-to choice for businesses looking for exceptional injection molding solutions.

Plastic Molding: The Clear Choice for Your Manufacturing Needs

Clear Plastic Molding, a leading plastic manufacturing company, has been making waves in the industry with its innovative and high-quality products. With a strong commitment to excellence and customer satisfaction, the company has established itself as a trusted name in the field of plastic molding.Established in 1995, Clear Plastic Molding has grown to become a major player in the plastic manufacturing industry. The company specializes in the production of a wide range of plastic products, including plastic containers, packaging materials, and custom-designed plastic components.With state-of-the-art facilities and a team of highly skilled professionals, Clear Plastic Molding is able to meet the needs of its diverse clientele. The company offers a comprehensive range of services, including product design, prototyping, tooling, and manufacturing. Its advanced manufacturing capabilities allow it to produce high-quality plastic products that meet the highest industry standards.The company's commitment to quality is evident in its rigorous quality control processes. Clear Plastic Molding adheres to strict quality standards at every stage of the manufacturing process, ensuring that its products are of the highest quality. This commitment to excellence has earned the company a stellar reputation in the industry.Clear Plastic Molding is also dedicated to sustainability and environmental responsibility. The company utilizes eco-friendly manufacturing processes and materials, minimizing its impact on the environment. It is committed to reducing waste and energy consumption, and is constantly exploring new ways to make its operations more sustainable.In addition to its focus on quality and sustainability, Clear Plastic Molding is also known for its outstanding customer service. The company works closely with its clients to understand their unique needs and requirements, and strives to provide personalized solutions that exceed their expectations. Its dedication to customer satisfaction has earned it a loyal customer base and numerous long-term partnerships.Recently, Clear Plastic Molding introduced a new line of innovative plastic products that have been creating quite a buzz in the industry. The company's advanced manufacturing techniques and cutting-edge design capabilities have allowed it to develop a range of unique and high-performance plastic products. From custom-designed components to specialized packaging solutions, Clear Plastic Molding is setting new standards for excellence in the industry.One of the company's most notable achievements is the development of a revolutionary new plastic packaging material that offers unprecedented durability and functionality. This innovative product has quickly gained recognition for its superior performance and has been widely adopted by leading brands across various industries.Clear Plastic Molding's relentless pursuit of excellence and innovation has positioned it as a trailblazer in the plastic manufacturing industry. With its unwavering commitment to quality, sustainability, and customer satisfaction, the company is poised to continue its upward trajectory and maintain its status as a leader in the industry. As the demand for high-quality plastic products continues to grow, Clear Plastic Molding is well-equipped to meet the diverse needs of its clients and deliver outstanding results.

High-Quality Plastic CNC Parts for Various Industries

CNC Plastic Part Company Introduces New High-Performance ProductCNC Plastic Part, a leading company in the field of precision plastic manufacturing, has recently introduced a new product that promises to deliver high-performance results for a wide range of applications. With a focus on meeting the demanding needs of industries such as automotive, aerospace, medical, and consumer electronics, CNC Plastic Part has made significant investments in research and development to create this innovative new product.The new product, which is being marketed under the brand name (please remove brand name), is designed to offer superior performance in terms of strength, durability, and precision. This is achieved through the use of advanced materials and cutting-edge manufacturing techniques that allow for tight tolerances and exceptional surface finishes.One of the key features of the (please remove brand name) product is its ability to withstand extreme temperatures and harsh environmental conditions, making it ideal for use in demanding applications where traditional plastic materials may not be suitable. This makes it a versatile solution for a wide range of industries, including those with stringent performance requirements.In addition to its high-performance capabilities, the (please remove brand name) product also offers the benefits of cost-effectiveness and efficiency. By leveraging CNC Plastic Part's expertise in precision manufacturing and its state-of-the-art production facilities, customers can expect to receive high-quality parts that meet their specifications while also enjoying the advantages of streamlined production processes and reduced lead times."We are excited to introduce this new product to the market," said a spokesperson for CNC Plastic Part. "We believe that it represents a significant advancement in the field of precision plastic manufacturing and will provide our customers with a competitive edge in their respective industries."In order to support the launch of the new (please remove brand name) product, CNC Plastic Part has also made investments in its quality control and testing capabilities to ensure that each part meets the highest standards of performance and reliability. This commitment to quality is reflective of the company's overall dedication to delivering products that meet or exceed customer expectations.CNC Plastic Part is known for its expertise in producing high-quality plastic components using CNC machining and injection molding techniques. With a focus on meeting the specific needs of its customers, the company offers a range of services, including design assistance, rapid prototyping, and full-scale production capabilities.The company's production facilities are equipped with the latest in CNC machining technology, allowing for the precise and efficient production of complex plastic components. This enables CNC Plastic Part to deliver parts with tight tolerances and intricate geometries, meeting the demanding requirements of its customers in various industries.In addition to its manufacturing capabilities, CNC Plastic Part also prides itself on providing exceptional customer service and support. The company's team of experienced engineers and technicians works closely with each customer to understand their unique requirements and develop tailored solutions to meet their needs.As the demand for high-performance plastic components continues to grow across various industries, CNC Plastic Part remains committed to staying at the forefront of innovation and delivering products that exceed customer expectations. The introduction of the new (please remove brand name) product is a testament to the company's ongoing dedication to providing cutting-edge solutions for its customers.With its focus on quality, performance, and customer satisfaction, CNC Plastic Part is well-positioned to meet the evolving needs of the market and maintain its status as a leader in the field of precision plastic manufacturing. The introduction of the new (please remove brand name) product is yet another example of the company's commitment to excellence and innovation.

High-Quality Plastic CNC Machining Parts for Custom Projects

Custom Plastic CNC Machining Parts - Delivering Precision and QualityIn today's rapidly evolving manufacturing industry, the demand for custom plastic CNC machining parts is at an all-time high. With the increasing need for precision and high-quality components, companies are turning to cutting-edge technologies to meet these requirements. One company at the forefront of this movement is {Company Name}.{Company Name} is a leading provider of custom CNC machining services, specializing in plastic parts for a wide range of industries such as automotive, aerospace, medical, and consumer electronics. With state-of-the-art facilities and a team of highly skilled engineers and technicians, {Company Name} has established itself as a trusted partner for businesses looking for reliable and cost-effective machining solutions.The key to {Company Name}'s success lies in its ability to deliver precision and quality in every component it produces. Utilizing advanced CNC machining equipment, the company is able to achieve tight tolerances and intricate designs, ensuring that each part meets the exact specifications of its customers. By leveraging the latest in CAD/CAM software and automation technologies, {Company Name} is able to streamline the manufacturing process, resulting in faster lead times and reduced costs for its clients.One of the standout features of {Company Name}'s CNC machining services is its ability to handle a wide variety of plastic materials. Whether it's ABS, acrylic, nylon, polycarbonate, or any other type of plastic, the company has the expertise and capabilities to machine these materials with the highest level of precision. This versatility allows {Company Name} to cater to the diverse needs of its clientele, ensuring that it can accommodate even the most challenging projects.Furthermore, {Company Name} understands the importance of quality control in the manufacturing process. With a rigorous inspection and testing protocol in place, each part undergoes thorough scrutiny to ensure that it meets the strictest quality standards. This dedication to quality has earned {Company Name} a reputation for reliability and consistency, making it a preferred choice for organizations seeking top-notch plastic CNC machining parts.In addition to its technical capabilities, {Company Name} places a strong emphasis on customer service and satisfaction. By working closely with its clients from the initial design phase to the final production stage, the company is able to provide tailored solutions that meet their specific needs. This collaborative approach has resulted in numerous successful partnerships and long-standing relationships with a diverse range of businesses.Looking ahead, {Company Name} is committed to staying at the forefront of the industry by investing in the latest advancements in CNC machining technology. By continuously upgrading its equipment and processes, the company aims to push the boundaries of what is achievable in precision plastic machining, setting new standards for the industry.In conclusion, the demand for custom plastic CNC machining parts is on the rise, driven by the need for precision and quality in today's manufacturing landscape. {Company Name} stands out as a leader in this field, offering advanced machining capabilities, material versatility, stringent quality control, and a customer-focused approach. With a track record of delivering exceptional results, the company is well-positioned to meet the growing demands of businesses across various industries, providing them with the custom plastic parts they need to succeed.

Custom Precision Turned Parts: A Complete Guide to Machined Components

Precision Turned Parts (PTP) is a leading manufacturer of high-quality turned parts for various industries. With a focus on precision and quality, PTP has been serving its customers with top-notch products for several years.Based in (location), PTP has a state-of-the-art facility that is equipped with the latest technology and machinery to produce turned parts with exact specifications. The company has a team of highly skilled and experienced engineers and technicians who are dedicated to delivering precision turned parts that meet the unique requirements of each customer.PTP offers a wide range of turned parts, including shafts, connectors, nuts, bolts, and many other custom components. The company has the capability to work with various materials such as aluminum, stainless steel, brass, and plastics, ensuring that they can cater to a diverse clientele.In addition to its extensive manufacturing capabilities, PTP also provides value-added services such as design assistance, prototyping, and assembly. This comprehensive approach allows the company to serve as a one-stop solution for all turned part needs.One of the key factors that set PTP apart from its competitors is its commitment to quality. The company adheres to strict quality control measures at every stage of the manufacturing process, ensuring that each turned part meets the highest standards. PTP is also certified to ISO 9001, further demonstrating its dedication to excellence.Furthermore, PTP is dedicated to staying at the forefront of its industry by investing in research and development. The company continuously explores new technologies and processes to improve its manufacturing capabilities and offer innovative solutions to its customers.PTP's commitment to quality, precision, and innovation has earned the trust and loyalty of its customers. The company has built strong, long-term relationships with clients from various industries, including automotive, aerospace, medical, and telecommunications.With a proven track record of delivering top-quality turned parts and exceptional customer service, PTP has established itself as a trusted partner for companies seeking reliable manufacturing solutions.In recent news, PTP has announced the addition of a new state-of-the-art CNC lathe to its production facility. This investment in advanced machining technology will further enhance the company's capabilities and allow it to meet the increasing demand for precision turned parts.The new CNC lathe boasts high-speed and high-precision machining capabilities, which will enable PTP to produce turned parts with even tighter tolerances and faster turnaround times. This acquisition aligns with PTP's commitment to staying ahead of the curve and providing its customers with the best possible solutions."We are excited to add this cutting-edge CNC lathe to our facility," said [Company Spokesperson]. "This investment reflects our dedication to meeting the evolving needs of our customers and maintaining our position as a leader in the turned parts industry."The addition of the new CNC lathe is just one example of PTP's ongoing efforts to improve its manufacturing capabilities and ensure customer satisfaction. The company remains focused on delivering top-quality turned parts that meet the highest standards of precision and reliability.As PTP continues to grow and innovate, it remains committed to its core values of quality, precision, and customer service. The company's unwavering dedication to excellence positions it as a preferred partner for businesses seeking reliable and high-quality turned part solutions. With its state-of-the-art facility, experienced team, and strong track record, PTP is poised to continue making a significant impact in the manufacturing industry.

Benefits of Rapid Injection Molding for Quick Manufacturing

Rapid Injection Molding Offers Quick and Efficient Production Solutions for Various IndustriesIn today's rapidly evolving market, companies are constantly looking for ways to streamline their production processes and bring their products to market faster. This need for speed and efficiency has given rise to the growing demand for rapid injection molding services. One company that has been leading the way in this space is {}. With their state-of-the-art technology and years of experience, they have been offering quick and efficient production solutions for various industries, making them a trusted partner for companies looking to accelerate their production timelines.The process of injection molding involves injecting molten material into a mold cavity to create a part. This method is widely used for the mass production of plastic parts, as it allows for high-quality, consistent parts to be produced at a rapid pace. However, traditional injection molding methods can be time-consuming and expensive, with long lead times and high tooling costs. This is where rapid injection molding comes in.Rapid injection molding is a fast and cost-effective alternative to traditional injection molding. It utilizes advanced technology and streamlined processes to reduce lead times and lower tooling costs, making it an ideal solution for companies looking to bring their products to market quickly and efficiently. By using rapid injection molding, companies can iterate their designs more quickly, reduce time to market, and ultimately gain a competitive edge in their industry.{} has been at the forefront of rapid injection molding, offering a wide range of services to meet the diverse needs of their clients. With a team of experienced engineers and technicians, they are able to provide comprehensive support throughout the entire production process, from design and prototyping to final part production. Their advanced manufacturing facilities are equipped with the latest injection molding machines and tooling technology, allowing them to produce high-quality parts with short lead times.One of the key advantages of partnering with {} for rapid injection molding is their ability to produce complex parts with precision and consistency. Their advanced tooling technology and process optimization allow for tight tolerances and high repeatability, ensuring that each part meets the strictest quality standards. This is particularly important for industries such as automotive, aerospace, and electronics, where complex and precise parts are a necessity.Additionally, {}'s rapid injection molding services are highly cost-effective, offering competitive pricing and low tooling costs. This makes it an attractive option for companies of all sizes, whether they are looking to produce a small batch of parts or scale up to high-volume production. With their quick turnaround times and efficient processes, companies can save time and money while still receiving high-quality parts.As the demand for rapid injection molding continues to grow, {} remains committed to staying at the forefront of the industry. They invest in cutting-edge technologies and continuously improve their processes to offer the best possible solutions for their clients. With a focus on innovation and customer satisfaction, they have built a solid reputation as a trusted partner for companies looking to accelerate their production timelines and bring their products to market faster.In conclusion, rapid injection molding has become a vital tool for companies looking to compete in today's fast-paced market. With its ability to produce high-quality parts quickly and cost-effectively, it offers a valuable advantage for businesses across various industries. Through their expertise and state-of-the-art technology, {} has established itself as a leading provider of rapid injection molding services, empowering companies to bring their innovative products to market with speed and efficiency.

The Ultimate Guide to Laser-Cut Foam Board: Tips, Techniques, and Benefits

Laser Cut Foam Board: Revolutionizing the IndustryIn the ever-evolving world of design and manufacturing, staying ahead of the curve is essential for companies seeking to remain competitive. This is especially true for the [Company Name], a leading provider of high-quality foam board solutions. The company has recently announced the launch of a new product that is set to revolutionize the industry – Laser Cut Foam Board.Laser Cut Foam Board is a cutting-edge material that combines the versatility of foam board with the precision of laser cutting technology. This innovative product offers a wide range of benefits, making it ideal for a variety of applications in industries such as packaging, signage, and model making.One of the key advantages of Laser Cut Foam Board is its high level of precision. The use of laser cutting technology ensures that each piece is cut to exact specifications, resulting in a perfect fit every time. This level of precision is especially important in industries where accuracy is paramount, such as in the creation of intricate packaging designs or detailed signage.Another benefit of Laser Cut Foam Board is its versatility. The material is available in a variety of thicknesses and colors, making it suitable for a wide range of applications. Whether it's creating eye-catching displays or building detailed architectural models, Laser Cut Foam Board offers the flexibility needed to bring any design to life.In addition to its precision and versatility, Laser Cut Foam Board also offers superior durability. The material is resistant to moisture, chemicals, and aging, ensuring that it can withstand the rigors of daily use without deteriorating. This durability makes it an ideal choice for long-lasting applications, such as outdoor signage or protective packaging.The introduction of Laser Cut Foam Board reflects [Company Name]'s commitment to innovation and meeting the changing needs of its customers. The company has a long history of providing high-quality foam board solutions, and the launch of this new product further solidifies its position as a leader in the industry.With a state-of-the-art manufacturing facility and a team of skilled professionals, [Company Name] is well-equipped to produce Laser Cut Foam Board to the highest standards. The company's dedication to quality and customer satisfaction ensures that each piece of Laser Cut Foam Board meets the strictest industry standards, providing customers with confidence in the reliability and performance of the product.In addition to its commitment to quality, [Company Name] is also dedicated to environmental sustainability. Laser Cut Foam Board is a recyclable material, underscoring the company's commitment to reducing its impact on the environment. By offering a product that is both high-performing and environmentally friendly, [Company Name] is taking a proactive approach to corporate responsibility.As [Company Name] continues to drive innovation in the foam board industry, the launch of Laser Cut Foam Board represents a significant milestone in the company's history. With its unparalleled precision, versatility, and durability, this new product is poised to revolutionize the way designers and manufacturers approach their projects. The introduction of Laser Cut Foam Board underscores [Company Name]'s position as a leader in the industry and sets a new standard for foam board solutions.With its cutting-edge technology and unwavering commitment to quality, [Company Name] is paving the way for a new era of design and manufacturing. As the company continues to push the boundaries of what is possible, one thing is certain – the future is bright for both [Company Name] and the industries it serves.

Custom Metal Box Welding and Bending Service: What You Need to Know

Metal fabrication plays a crucial role in today's manufacturing and construction industries, providing the necessary components for a wide range of products and structures. One company that has been at the forefront of delivering high-quality metal fabrication services is Metal Box Welding Bending Service.Metal Box Welding Bending Service is a leading provider of metal fabrication solutions, specializing in welding, bending, and assembly services. With a strong focus on precision and quality, the company has built a reputation for delivering exceptional results to its clients.The company's state-of-the-art facilities are equipped with the latest technology and machinery, allowing them to take on projects of varying complexity and scale. Their team of skilled technicians and engineers are dedicated to meeting the unique needs of each client, ensuring that every project is completed to the highest standards.Metal Box Welding Bending Service has a diverse portfolio of clients, including those in the automotive, aerospace, and construction industries. Their ability to adapt to the specific requirements of each industry has made them a trusted partner for many businesses looking for reliable metal fabrication solutions.One of the key strengths of Metal Box Welding Bending Service is their commitment to innovation and continuous improvement. The company regularly invests in research and development to stay ahead of industry trends and maintain their competitive edge. This approach has allowed them to not only meet the current demands of their clients, but also anticipate future needs and develop new solutions to address them.Another factor that sets Metal Box Welding Bending Service apart from other metal fabrication companies is their emphasis on environmental sustainability. The company's manufacturing processes and materials are carefully selected to minimize their impact on the environment, reflecting their commitment to responsible and ethical business practices.In addition to their impressive technical capabilities, Metal Box Welding Bending Service also places a high value on customer service. They work closely with their clients throughout every step of the project, from initial design concepts to final delivery, ensuring that their needs and expectations are fully met.With their unmatched expertise and dedication to excellence, Metal Box Welding Bending Service continues to be a driving force in the metal fabrication industry, setting the standard for quality and innovation.As the demand for metal fabrication services continues to grow, Metal Box Welding Bending Service remains at the forefront of the industry, providing reliable solutions to a diverse range of clients. With their commitment to quality, innovation, and customer satisfaction, the company is well-positioned to continue leading the way in the ever-evolving world of metal fabrication.

High-Quality CNC Turned Components for Various Industries

CNC Turned Components- The Backbone of Precision EngineeringIn the world of precision engineering, CNC turned components play a crucial role in the manufacturing of various products. These components are used in a wide range of industries, including aerospace, automotive, medical, and electronics, to produce intricate and precise parts that are essential for the functioning of mechanical systems. With the advancement of technology, the demand for high-quality CNC turned components has increased, and companies like {} have been at the forefront of delivering top-notch solutions in this field.{} is a leading manufacturer of CNC turned components, specializing in producing precision parts for a diverse range of industries. With state-of-the-art facilities and a team of highly skilled engineers and technicians, the company has established itself as a trusted provider of CNC turned components for both domestic and international markets.The use of CNC (Computer Numerical Control) technology allows {} to manufacture components with a high degree of accuracy and consistency. This technology ensures that each component meets the required specifications, regardless of the complexity of the design. Additionally, CNC machining allows for a faster production process, reducing lead times and increasing overall efficiency.One of the key advantages of CNC turned components is their versatility. They can be manufactured from a wide variety of materials, including aluminum, steel, brass, and plastic, to meet the specific requirements of different applications. This flexibility makes CNC turned components an ideal choice for a diverse range of industries, where the demand for precision and quality is paramount.The aerospace industry is one of the major beneficiaries of CNC turned components. Aircraft and spacecraft require a multitude of intricate parts that must meet stringent standards for quality and performance. {} has been a key supplier to the aerospace industry, providing critical components that contribute to the safety and reliability of aircraft and spacecraft.In the automotive industry, CNC turned components are widely used in the manufacturing of engines, transmissions, and suspension systems, among other applications. The high precision and durability of these components are essential for ensuring the optimal performance and safety of vehicles. {} has been a trusted partner to numerous automotive manufacturers, delivering reliable CNC turned components that meet the industry's exacting standards.The medical industry is another sector that relies heavily on CNC turned components for the production of medical devices and equipment. From surgical instruments to diagnostic devices, the use of precision components is crucial for the functionality and accuracy of medical technologies. {} has played a pivotal role in supplying CNC turned components that have been instrumental in advancing medical innovations and improving patient care.In the electronics industry, the demand for miniaturization and high precision has driven the need for CNC turned components that can meet these requirements. {} has been at the forefront of meeting these demands, delivering components that enable the seamless integration of electronic systems in various applications, from consumer electronics to industrial automation.As a leading manufacturer of CNC turned components, {} is committed to maintaining the highest standards of quality and precision in its production processes. The company's stringent quality control measures ensure that each component meets the exact specifications and tolerances required by its customers. With a focus on continuous improvement and innovation, {} remains dedicated to pushing the boundaries of what is possible in CNC machining, delivering solutions that exceed customer expectations.In conclusion, CNC turned components are the backbone of precision engineering, playing a critical role in the manufacturing of products across a wide range of industries. With its commitment to excellence and innovation, {} has solidified its position as a trusted provider of high-quality CNC turned components, contributing to the advancement of technology and the success of its customers.

Silicone Rubber Seal Auto Part for Multi Pin Connectors

[Company Name], a leading manufacturer of high-quality automotive components, has recently announced the release of their new Multi Pin Connector Silicone Rubber Seal Auto Part. This innovative product is designed to provide superior protection and sealing for multi pin connectors, ensuring optimal performance and durability in automotive electronic systems.The Multi Pin Connector Silicone Rubber Seal Auto Part is a vital component in automotive electrical systems, as it helps to prevent moisture, dust, and other contaminants from infiltrating the connector. This is particularly important in modern vehicles, which are equipped with a wide range of electronic components that must remain operational in various environmental conditions.[Company Name] has leveraged its extensive experience and expertise in the automotive industry to develop a durable and reliable silicone rubber seal that meets the stringent requirements of automotive manufacturers and aftermarket suppliers. The company's commitment to quality and innovation is evident in this new product, which is designed to withstand the harsh conditions of the automotive environment and provide long-lasting protection for multi pin connectors."We are excited to introduce our Multi Pin Connector Silicone Rubber Seal Auto Part to the market," said [Spokesperson Name], [Title] at [Company Name]. "This product is the result of our dedication to engineering excellence and our focus on meeting the evolving needs of the automotive industry. We believe that it will be a valuable addition to our portfolio of automotive components and will help our customers deliver reliable and durable electronic systems in their vehicles."In addition to its superior protective properties, the Multi Pin Connector Silicone Rubber Seal Auto Part also offers ease of installation, thanks to its flexible and adaptable design. This makes it an ideal solution for automotive manufacturers, as well as aftermarket suppliers and repair shops that need to replace or upgrade multi pin connector seals in existing vehicles.As part of its commitment to customer satisfaction, [Company Name] ensures that the Multi Pin Connector Silicone Rubber Seal Auto Part meets the highest quality standards. The product undergoes rigorous testing and inspection processes to validate its performance and durability, giving customers the confidence that it will deliver the expected results in demanding automotive applications.Furthermore, [Company Name] provides comprehensive technical support and assistance to its customers, helping them to integrate the Multi Pin Connector Silicone Rubber Seal Auto Part into their products or services. The company's team of automotive experts is available to collaborate with customers on custom solutions and to address specific challenges related to multi pin connector sealing in electronic systems.With the release of the Multi Pin Connector Silicone Rubber Seal Auto Part, [Company Name] reaffirms its position as a trusted partner for automotive manufacturers and aftermarket suppliers seeking high-quality components and innovative solutions. The company's dedication to excellence and its relentless pursuit of technological advancement continue to drive its success in the competitive automotive industry.In conclusion, the introduction of the Multi Pin Connector Silicone Rubber Seal Auto Part highlights [Company Name]'s commitment to delivering cutting-edge solutions that address the evolving needs of the automotive industry. This innovative product is poised to make a significant impact on the performance and reliability of electronic systems in vehicles, providing customers with a durable and effective sealing solution for multi pin connectors. [Company Name]'s expertise, dedication to quality, and customer-centric approach position it as a leading provider of automotive components, capable of meeting the most demanding requirements of its customers.