High-Quality Rubber Parts for a Variety of Applications

By:Admin

The [Company Name] has a rich history of providing top-notch rubber parts to a wide range of industries including automotive, aerospace, electronics, and more. Their commitment to research and development has allowed them to stay ahead of the curve and continuously introduce new and improved products to meet the evolving needs of their customers.

With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, the [Company Name] has the capability to design and produce custom rubber parts to meet the specific requirements of their clients. Whether it’s rubber seals, gaskets, O-rings, or any other component, the company has the expertise to deliver solutions that exceed expectations.

One of the key strengths of the [Company Name] is their focus on quality control. Every product undergoes rigorous testing to ensure that it meets the highest standards for performance and durability. This commitment to quality has earned the company a reputation for reliability and consistency, making them the go-to choice for businesses looking for superior rubber parts.

The company’s dedication to innovation is another factor that sets them apart from the competition. They are constantly investing in research and development to explore new materials and manufacturing techniques, with the goal of creating rubber parts that deliver superior performance and longevity. This dedication to pushing the boundaries of what’s possible in rubber technology has made the [Company Name] an industry leader.

In addition to their focus on quality and innovation, the [Company Name] also takes pride in their commitment to customer satisfaction. They understand that every business has unique needs and challenges, and they work closely with their clients to provide customized solutions that address those specific requirements. From the initial design phase to the final delivery, the company’s team of experts is there every step of the way to ensure a seamless and successful partnership.

The release of the latest line of rubber parts from the [Company Name] underscores their unwavering dedication to excellence. Whether it’s for automotive applications, industrial machinery, or consumer electronics, these new products are designed to deliver superior performance and reliability, making them a valuable asset for businesses in a wide variety of industries.

As the demand for high-quality rubber parts continues to grow, the [Company Name] is well-positioned to meet the needs of their customers. With their focus on quality, innovation, and customer satisfaction, they are poised to remain a leader in the industry for years to come.

For businesses in need of top-notch rubber parts, the [Company Name] is the partner of choice. With their proven track record of excellence and a commitment to pushing the boundaries of what’s possible, they are a trusted source for high-performance rubber solutions.

To learn more about the [Company Name] and their latest line of rubber parts, visit their website at [companywebsite.com] or contact their team directly for more information. With their expertise and dedication, the company stands ready to meet the rubber part needs of businesses around the world.

Company News & Blog

High-Quality Adhesive Rubber Bumper Strip for Home and Industrial Use

Adhesive Rubber Bumper Strip, the latest innovation from leading company in rubber and plastic technology, is set to revolutionize the industry with its versatile application and durable performance.With over 30 years of experience in the rubber and plastic industry, the company has established itself as a leader in providing high-quality and innovative solutions to its customers. The introduction of the Adhesive Rubber Bumper Strip is a testament to the company's commitment to developing cutting-edge products that meet the needs of its clients.The Adhesive Rubber Bumper Strip is designed to provide protection and cushioning in a wide range of applications. With its strong adhesive backing, it can be easily applied to various surfaces, including wood, metal, and plastic, making it ideal for use in furniture, electronics, and automotive industries.One of the key features of the Adhesive Rubber Bumper Strip is its ability to absorb and distribute impact, reducing the risk of damage to delicate surfaces and components. This makes it an ideal solution for preventing scratches, dents, and other forms of damage in both commercial and residential settings.In addition to its protective properties, the Adhesive Rubber Bumper Strip also offers excellent grip and traction, making it suitable for use in applications where slip resistance is essential. Its durable construction ensures long-lasting performance, even in high-traffic areas.The company's commitment to quality and innovation is reflected in the rigorous testing and development process that the Adhesive Rubber Bumper Strip has undergone. Through extensive research and development, the company has created a product that meets the highest standards of performance and reliability."We are proud to introduce the Adhesive Rubber Bumper Strip to the market," said [company spokesperson]. "This product is the result of our dedication to providing our customers with innovative solutions that meet their specific needs. We believe that the Adhesive Rubber Bumper Strip will set a new standard for performance and versatility in the industry."The Adhesive Rubber Bumper Strip is available in a variety of sizes and thicknesses to accommodate different applications. It can also be customized to meet specific requirements, making it a versatile solution for a wide range of industries.With its ability to provide excellent protection, grip, and durability, the Adhesive Rubber Bumper Strip is poised to become a go-to solution for manufacturers, retailers, and consumers alike. Its ease of use and versatility make it an attractive option for anyone looking to protect surfaces and equipment from damage.For more information about the Adhesive Rubber Bumper Strip and to inquire about customization options, visit [company website] or contact [company representative] at [contact information].

Durable Foam Rubber Gasket for Multiple Applications

Foam Rubber Gasket Becomes the Go-To Choice for Sealing SolutionsIn the world of manufacturing and engineering, the importance of quality sealing solutions cannot be overstated. Whether it's for protecting electronics from moisture or creating a tight seal in industrial machinery, the right gasket can make all the difference. That's where Foam Rubber Gasket, a leading manufacturer of high-quality sealing products, comes in.With a strong commitment to quality, innovation, and customer satisfaction, Foam Rubber Gasket has established itself as a trusted industry leader in the field of sealing solutions. Since its inception, the company has focused on developing and manufacturing top-of-the-line gaskets that are designed to meet the diverse needs of its customers.One of the key reasons for the popularity of Foam Rubber Gasket's products is their unwavering commitment to quality. By using the latest manufacturing techniques and state-of-the-art materials, the company ensures that every gasket it produces meets the highest standards of performance and reliability. This dedication to quality has earned Foam Rubber Gasket a stellar reputation in the industry, making it the go-to choice for companies that demand nothing but the best.In addition to its focus on quality, Foam Rubber Gasket is also known for its commitment to innovation. The company's team of experienced engineers and technicians are constantly exploring new ways to improve the performance and durability of its products. Whether it's through the use of advanced materials, cutting-edge manufacturing processes, or innovative design concepts, Foam Rubber Gasket is always pushing the boundaries of what's possible in the world of sealing solutions.As a result of this commitment to excellence, Foam Rubber Gasket has been able to develop a wide range of gaskets that are suitable for a variety of applications. From simple O-rings to complex custom-designed seals, the company offers a comprehensive selection of products that can meet the needs of virtually any industry. This versatility has made Foam Rubber Gasket a favorite among manufacturers, engineers, and maintenance professionals who require reliable sealing solutions for their projects.Another factor that sets Foam Rubber Gasket apart from its competitors is its unwavering dedication to customer satisfaction. The company understands that every client has unique requirements and challenges, and it is committed to providing personalized service to each and every customer. Whether it's through the development of custom sealing solutions or the provision of expert technical support, Foam Rubber Gasket goes above and beyond to ensure that its clients have everything they need to succeed.One of the flagship products offered by Foam Rubber Gasket is its line of foam rubber gaskets. These specially designed gaskets are made from high-quality foam rubber that offers an exceptional combination of flexibility, resilience, and sealing properties. Whether it's used in automotive applications, electronic devices, or industrial equipment, foam rubber gaskets from Foam Rubber Gasket are designed to provide reliable and long-lasting performance.The success of Foam Rubber Gasket's foam rubber gaskets can be attributed to the company's meticulous attention to detail and unwavering commitment to quality. By using the finest materials and the most advanced manufacturing techniques, Foam Rubber Gasket ensures that its foam rubber gaskets offer outstanding performance in even the most demanding applications. With a wide range of sizes, shapes, and configurations available, customers can easily find the perfect foam rubber gasket for their specific needs.In conclusion, the combination of quality, innovation, and customer satisfaction has solidified Foam Rubber Gasket's position as a leading provider of sealing solutions. With its commitment to excellence and a comprehensive range of high-performance products, the company continues to be the go-to choice for companies that demand nothing but the best in sealing solutions. For anyone in need of top-quality gaskets, Foam Rubber Gasket is the name to trust.

High-Quality Plastic Mold Components for Various Industries

Plastic Mold Components, a renowned and respected company in the industry, has made a name for itself by providing high-quality and innovative products for the plastic molding industry. With a strong emphasis on precision and reliability, the company has established itself as a leading supplier of mold components and tooling solutions for a wide range of applications.The company's extensive product line includes a variety of mold bases, mold components, hot runner systems, and other essential components for plastic injection molding. These products are designed to meet the demanding requirements of the industry and are built to deliver exceptional performance and durability.One of the key strengths of Plastic Mold Components is its commitment to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve and bring cutting-edge solutions to its customers. This dedication to innovation has enabled the company to develop a range of patented technologies and proprietary products that have set new standards in the industry.In addition to its focus on innovation, Plastic Mold Components is also dedicated to providing superior customer service and support. The company's team of skilled and experienced professionals is committed to working closely with customers to understand their specific needs and provide tailored solutions. Whether it's assisting with product selection, offering technical support, or providing onsite assistance, the team at Plastic Mold Components is always ready to go the extra mile to ensure customer satisfaction.Furthermore, the company's commitment to quality is evident in its rigorous quality control processes and adherence to industry standards. All products undergo strict testing and inspection to ensure they meet the highest standards for performance, reliability, and safety. This dedication to quality has earned Plastic Mold Components a reputation for excellence and reliability in the industry.Beyond its commitment to quality and innovation, Plastic Mold Components also places a strong emphasis on sustainability and environmental responsibility. The company is dedicated to minimizing its environmental footprint and continuously seeks ways to reduce waste, conserve resources, and operate in an environmentally friendly manner. This commitment to sustainability is not only reflected in the company's products but also in its operations and business practices.Looking ahead, Plastic Mold Components is poised for continued growth and success in the industry. With a strong foundation built on quality, innovation, and customer satisfaction, the company is well-positioned to meet the evolving needs of the plastic molding industry and continue to drive progress and excellence.In conclusion, Plastic Mold Components stands as a trusted partner and supplier for companies in the plastic molding industry. With a commitment to quality, innovation, and customer satisfaction, the company continues to deliver cutting-edge solutions and set new standards in the industry. As the company looks to the future, it remains dedicated to driving progress, sustainability, and success in the industry.

Durable Waterproof Rubber Grommets for Various Applications

[Company Introduction: Company X is a leading manufacturer in the industry, specializing in producing high-quality rubber and plastic products for various applications. With years of experience and expertise, Company X has gained a reputation for delivering reliable and durable solutions for customers worldwide.]Waterproof Rubber Grommets: Providing a Reliable Solution for Various ApplicationsRubber grommets are indispensable components in many industries, providing a sealing and cushioning solution for a wide range of applications. Whether used in automotive, electrical, plumbing, or other industries, grommets play a crucial role in protecting wires, cables, and hoses from wear and tear caused by friction or exposure to moisture. Furthermore, with the increasing demand for high-quality and durable grommets, Company X has introduced its latest innovation – the Waterproof Rubber Grommets.Designed to provide superior protection against moisture and environmental factors, Company X's Waterproof Rubber Grommets are engineered to withstand the harshest conditions while maintaining their reliability and performance. Unlike traditional rubber grommets, which may degrade or become damaged when exposed to water or humidity, the waterproof grommets are constructed using specialized materials and manufacturing techniques to ensure their durability and resilience.The key features of Company X's Waterproof Rubber Grommets include:1. Superior Waterproofing: The grommets are designed to prevent water and moisture from penetrating through the seal, ensuring that the cables and wires are kept dry and insulated from external elements.2. High-Temperature Resistance: In addition to being waterproof, the grommets are also capable of withstanding high temperatures, making them ideal for use in automotive and industrial applications where the risk of heat exposure is significant.3. Durable and Long-Lasting: Company X's Waterproof Rubber Grommets are built to last, with a focus on longevity and reliability. They are resistant to tearing, abrasion, and degradation, ensuring that they can withstand the rigors of daily use.4. Versatile Application: The grommets are suitable for a wide range of applications, including automotive wiring, marine equipment, electrical panels, and outdoor installations, where protection from moisture is essential.By introducing these innovative Waterproof Rubber Grommets, Company X aims to provide customers with a reliable solution for their sealing and insulation needs, particularly in environments where moisture and water exposure are prevalent. The company understands the importance of delivering products that not only meet industry standards but also exceed customer expectations in terms of performance and durability.In line with its commitment to quality and innovation, Company X has invested in state-of-the-art manufacturing facilities and R&D capabilities to develop and produce the Waterproof Rubber Grommets. The company's engineering team has conducted extensive testing and validation to ensure that the grommets meet the highest standards for waterproofing and reliability.Moreover, Company X's dedication to sustainable and environmentally friendly practices is reflected in the materials and production processes used for the Waterproof Rubber Grommets. By adhering to strict quality control measures and environmental regulations, the company ensures that its products not only perform exceptionally but also contribute to a greener and more sustainable future.As the demand for waterproof grommets continues to grow across various industries, Company X is poised to be at the forefront of providing innovative solutions that address the evolving needs of its customers. With its unwavering commitment to excellence and customer satisfaction, the company remains a trusted partner for businesses seeking reliable and high-quality rubber and plastic products.In conclusion, Company X's introduction of the Waterproof Rubber Grommets represents a significant milestone in the industry, offering a game-changing solution for sealing and insulation in challenging environments. The company's dedication to innovation, quality, and sustainability reinforces its position as a leader in the manufacturing of rubber and plastic products, and it is poised to make a lasting impact with its latest innovation.

Injection Molding: A Guide to IML Technology

Iml Injection Molding is a leading manufacturing process that has revolutionized the production of plastic parts. This innovative technology has allowed companies to produce high-quality, durable, and intricate plastic components with unparalleled precision and efficiency. With the use of advanced machinery, high-grade materials, and sophisticated software, Iml Injection Molding has become the preferred choice for many industries, including automotive, electronics, consumer goods, and medical devices. The process involves injecting molten plastic into a mold cavity, where it is shaped and cooled to form a finished product. The In-Mold Labeling (IML) technology further enhances the product by incorporating the label or decoration directly into the mold, resulting in a seamless and durable finish.The company {} has been at the forefront of this technological advancement, offering a wide range of Iml Injection Molding solutions to meet the diverse needs of its clients. With state-of-the-art facilities, a highly skilled workforce, and a commitment to excellence, {} has established itself as a reliable and innovative partner for businesses seeking top-notch plastic manufacturing services.{} specializes in custom mold design and fabrication, precision injection molding, and in-mold labeling for various industries. From automotive interior parts and electronic housings to food packaging and medical devices, {} has the expertise and capabilities to deliver complex and high-quality plastic components that meet the highest industry standards.One of the key advantages of Iml Injection Molding is its ability to produce parts with intricate designs and complex geometries. This is made possible through the use of specialized molds and advanced machinery that can achieve tight tolerances and superior surface finishes. As a result, products manufactured using Iml Injection Molding are not only visually appealing but also functionally superior, making them ideal for a wide range of applications.In addition to its technical capabilities, {} places a strong emphasis on sustainability and environmental responsibility. The company is committed to using recyclable materials, reducing waste, and optimizing energy consumption in its manufacturing processes. By adopting eco-friendly practices, {} not only contributes to a healthier planet but also helps its clients meet their sustainability goals.Moreover, {} is dedicated to continuous improvement and innovation. The company invests in research and development to stay ahead of the latest industry trends and technology advancements. By embracing new materials, processes, and design techniques, {} ensures that its clients receive cutting-edge solutions that give them a competitive edge in their respective markets.As a customer-centric company, {} prides itself on its ability to provide tailored solutions that meet the unique requirements of each client. By collaborating closely with its customers, {} gains a deep understanding of their needs and preferences, allowing the company to deliver personalized and cost-effective Iml Injection Molding solutions that exceed expectations.With a strong track record of delivering exceptional results, {} has earned the trust and loyalty of its clients, who rely on the company for their most demanding plastic manufacturing projects. By consistently delivering top-quality products, on-time delivery, and responsive customer service, {} has built a reputation as a partner that businesses can depend on for their Iml Injection Molding needs.In conclusion, Iml Injection Molding is a game-changer in the world of plastic manufacturing, and {} is at the forefront of this technological revolution. With its advanced capabilities, commitment to sustainability, and customer-centric approach, {} is well-positioned to continue leading the way in delivering high-quality and innovative Iml Injection Molding solutions. Businesses seeking a reliable and forward-thinking manufacturing partner need look no further than {}.

Plastic Machining Prototype: A Complete Guide

CNC Plastic Machining Prototype: Revolutionizing the Manufacturing IndustryIn a world where precision and efficiency are key components for success in the manufacturing industry, the use of advanced technologies such as CNC plastic machining prototypes has become increasingly important. With the ability to create high-quality, precise plastic components with unmatched speed and accuracy, this groundbreaking technology has the potential to revolutionize the way products are developed and manufactured.The use of CNC (Computer Numerical Control) technology in plastic machining has significantly improved the manufacturing process. This revolutionary technology allows for the automated control of machining tools using a computer program, resulting in highly precise and consistent plastic components. By leveraging the power of CNC plastic machining prototypes, companies can significantly reduce production time and costs, while delivering top-quality products to their customers.In the midst of this technological revolution, one company stands out as a leader in the field of CNC plastic machining prototypes. {Company} is a renowned manufacturer and supplier of cutting-edge CNC plastic machining solutions. With a strong focus on innovation and cutting-edge technology, {Company} has established itself as a trusted partner for businesses seeking high-quality plastic machining prototypes.{Company} has consistently demonstrated a commitment to excellence and innovation in the field of CNC plastic machining prototypes. Their state-of-the-art manufacturing facility is equipped with the latest CNC machines, allowing them to produce top-quality plastic components with unmatched precision and accuracy. Coupled with a team of highly skilled engineers and technicians, {Company} has the expertise and resources to meet the evolving needs of the manufacturing industry.The use of CNC plastic machining prototypes from {Company} has had a profound impact on the manufacturing industry. By leveraging this advanced technology, companies can accelerate the product development process, reduce production lead times, and minimize material wastage. Additionally, the high precision and repeatability of CNC plastic machining prototypes ensure that companies can consistently deliver products that meet the highest quality standards.{Company}'s commitment to delivering excellence extends beyond just the technology. With a strong emphasis on customer satisfaction, {Company} works closely with businesses to understand their specific requirements and deliver tailored solutions that meet their needs. The company's dedication to customer service and support has further solidified its reputation as a trusted partner for businesses seeking reliable and efficient CNC plastic machining prototypes.The impact of CNC plastic machining prototypes goes beyond just the manufacturing process. By streamlining production and improving efficiency, companies can reduce their environmental footprint and contribute to a more sustainable future. The ability to produce high-quality plastic components with minimal material wastage has the potential to revolutionize the way products are manufactured, paving the way for a more sustainable and environmentally friendly manufacturing industry.As the manufacturing industry continues to evolve, the demand for high-quality, precision plastic components will only grow. With the versatility and efficiency of CNC plastic machining prototypes, companies can stay ahead of the curve and meet the demands of an ever-changing market. {Company} remains at the forefront of this technological revolution, continuously pushing the boundaries of innovation and excellence in CNC plastic machining prototypes.In conclusion, the use of CNC plastic machining prototypes has the potential to revolutionize the manufacturing industry. With its unmatched precision, speed, and efficiency, this groundbreaking technology is poised to transform the way products are developed and manufactured. {Company} continues to lead the charge in this technological revolution, delivering top-quality CNC plastic machining solutions that meet the evolving needs of the industry. As businesses continue to seek innovative solutions for their manufacturing needs, the use of CNC plastic machining prototypes from {Company} will undoubtedly play a crucial role in shaping the future of the industry.

Customized CNC Turning and Milling Parts Manufacturer from China

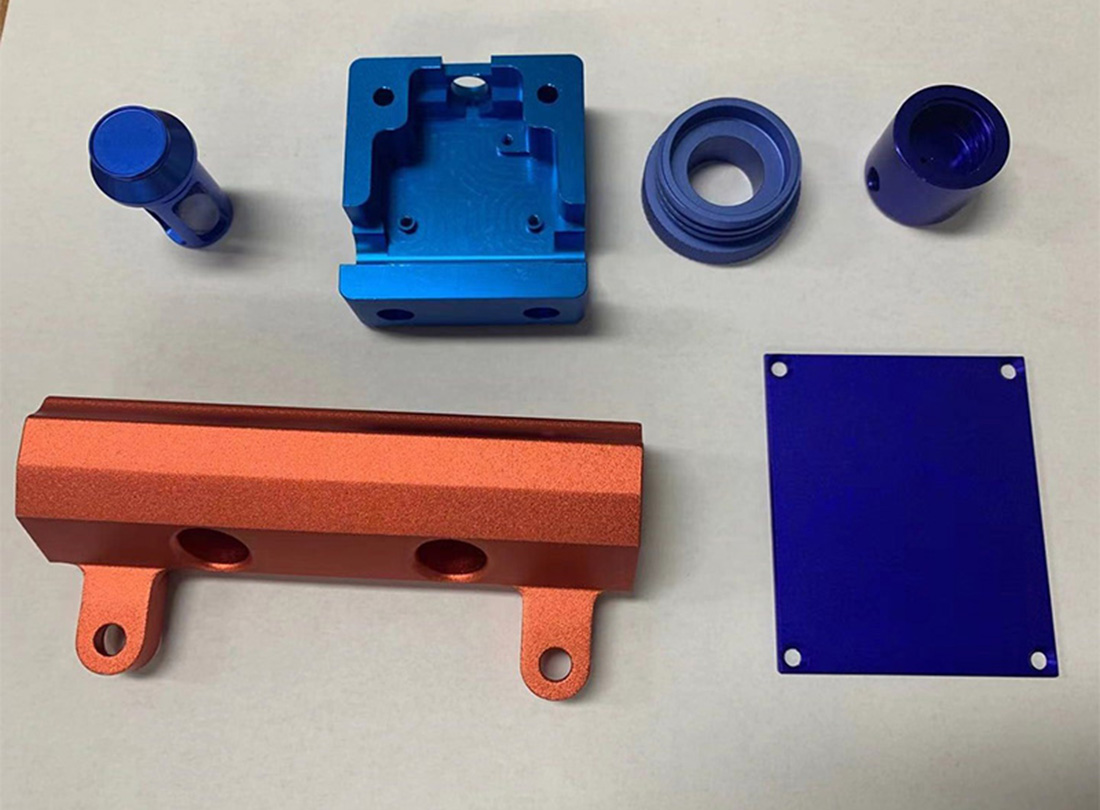

In today's fast-paced manufacturing industry, the demand for high-quality CNC turning and milling parts is on the rise. As industries across the world continue to rely on precision engineering and advanced technology, the need for reliable and efficient CNC parts manufacturers has never been greater. This is where our company, a leading CNC turning parts manufacturer and CNC milling parts factory in China, comes into the picture.With a strong emphasis on quality, precision, and customer satisfaction, our company has established itself as a trusted provider of CNC turning and milling parts for a wide range of industries, including automotive, aerospace, medical, and electronics. Our state-of-the-art manufacturing facilities, advanced machinery, and skilled workforce enable us to produce a diverse range of high-precision components that meet the stringent requirements of our global clientele.As a leading CNC turning parts manufacturer, we specialize in producing a wide variety of components, including shafts, bushings, connectors, and fasteners, among others. Our CNC turning process allows us to create complex geometries and achieve tight tolerances with ease, ensuring that our parts meet the exact specifications of our customers. Additionally, our CNC milling capabilities enable us to machine intricate shapes and contours, providing our clients with highly customized solutions for their specific applications.At our CNC milling parts factory, we prioritize innovation and continuous improvement in our manufacturing processes. Our team of skilled engineers and technicians leverages the latest CAD/CAM software and advanced machining techniques to optimize production efficiency and ensure the highest level of accuracy and consistency in our parts. This commitment to excellence has earned us a reputation as a reliable and responsive partner for companies seeking precision-engineered components.In addition to our technical expertise, our company is also dedicated to upholding the highest standards of quality and reliability. We adhere to strict quality control measures at every stage of the production process, from raw material inspection to final product testing. This rigorous approach enables us to deliver CNC turning and milling parts that consistently exceed industry standards and exceed customer expectations.Furthermore, our company is committed to sustainability and environmental responsibility. We have implemented eco-friendly manufacturing practices and comply with all relevant regulations and standards to minimize our environmental impact. By prioritizing sustainability, we aim to contribute to a more environmentally conscious and sustainable future for the manufacturing industry.With our unwavering dedication to quality, precision, and customer satisfaction, our company has established itself as a trusted CNC turning parts manufacturer and CNC milling parts factory in China. Whether it's a small prototype run or a large-scale production order, we have the capabilities and expertise to deliver high-quality CNC parts that meet the most demanding requirements of our clients.As we look towards the future, we remain committed to pushing the boundaries of innovation and excellence in CNC machining. By continuously investing in advanced technology, expanding our capabilities, and nurturing our talented workforce, we are poised to remain at the forefront of the industry and continue to provide our customers with the highest quality CNC turning and milling parts.

High-Quality Precision Turning Components for CNC Machining Operations

CNC Precision Turning ComponentsIn the world of manufacturing, precision is key. Products must be made with exacting accuracy in order to meet the demands of modern consumers. This is where CNC precision turning components come into play. These components are an essential part of the manufacturing process, providing the precision and accuracy needed to create high-quality products.{Company Name} is a leading provider of CNC precision turning components. With years of experience and a dedication to quality, they have become a trusted name in the industry. Their components are used in a wide range of applications, including aerospace, automotive, and medical equipment. They are capable of producing components with tight tolerances and complex geometries, making them a valuable partner for companies looking to produce top-quality products.One of the key advantages of CNC precision turning components is their ability to produce parts with minimal human intervention. The CNC (Computer Numerical Control) technology used in these components allows for highly precise and consistent production, with minimal risk of error. This not only improves the quality of the products, but also reduces the time and cost of production.{Company Name}'s CNC precision turning components are made using state-of-the-art equipment and the latest manufacturing techniques. This allows them to produce components with exceptional accuracy and reliability. Their team of skilled engineers and technicians work closely with clients to develop custom solutions for their specific needs, ensuring that the final product meets their exact specifications.In addition to their precision and reliability, {Company Name}'s CNC precision turning components are also known for their versatility. They can be used to produce a wide range of parts and components, including shafts, valves, fittings, and much more. This flexibility makes them a valuable resource for companies looking to streamline their manufacturing processes and improve their overall efficiency.The demand for CNC precision turning components continues to grow, as manufacturers seek to improve the quality and performance of their products. As a result, {Company Name} is constantly expanding and upgrading their capabilities to meet the needs of their clients. They are committed to staying at the forefront of CNC technology, ensuring that their components are always at the cutting edge of the industry.With their dedication to quality, precision, and innovation, {Company Name} has solidified their position as a leader in the field of CNC precision turning components. Their components are trusted by companies around the world to produce high-quality products with unmatched accuracy and reliability. As the demand for precision manufacturing continues to grow, {Company Name} is well-positioned to meet the needs of their clients and continue to push the boundaries of what is possible in modern manufacturing.In conclusion, CNC precision turning components are an essential part of modern manufacturing, allowing companies to produce high-quality products with exceptional precision and reliability. {Company Name} is a trusted provider of these components, with a proven track record of delivering top-quality solutions to their clients. Their dedication to innovation and quality makes them a valuable partner for companies looking to take their manufacturing processes to the next level.

Benefits of Laser Prototyping for Rapid Product Development

Laser Prototyping Technology Revolutionizes Manufacturing IndustryThe manufacturing industry is constantly evolving, with new technologies and advancements changing the way products are developed and produced. One of the most recent and groundbreaking innovations in the industry is the use of laser prototyping technology. This cutting-edge technology is revolutionizing the manufacturing process by allowing companies to create high-quality prototypes and production parts with unmatched speed and precision.Laser prototyping, also known as rapid prototyping, is a process that uses a high-powered laser to selectively sinter powdered materials, such as metals, plastics, or ceramics, layer by layer to create three-dimensional objects. This technology is incredibly versatile and can be used to produce complex geometries and intricate designs that would be difficult or impossible to achieve using traditional manufacturing methods. Furthermore, laser prototyping allows for rapid iteration and customization, making it an ideal solution for companies in need of quick turnaround times and flexible production capabilities.One company at the forefront of laser prototyping technology is {}. Founded in 1999, {} has been a pioneer in the development and implementation of advanced laser systems for a wide range of industrial applications. With a strong focus on innovation and customer satisfaction, {} has continuously pushed the boundaries of what is possible with laser technology, creating solutions that have redefined the manufacturing industry.{}'s laser prototyping systems utilize state-of-the-art laser sources and advanced powder bed fusion techniques to deliver exceptional part quality and dimensional accuracy. The company's integrated software and hardware solutions enable precise control over the laser sintering process, allowing for the creation of highly detailed and functional prototypes and production parts. In addition, {}'s laser systems are designed for scalability, making them suitable for small-scale rapid prototyping as well as large-scale industrial production.The benefits of laser prototyping technology extend beyond its technical capabilities. By streamlining the product development cycle and reducing the need for expensive tooling and machining, laser prototyping can significantly lower production costs and time to market. This has a direct impact on a company's bottom line and overall competitiveness in the market. Furthermore, the ability to quickly iterate and test designs allows for more efficient development processes and ultimately leads to better end products.In recent years, {} has seen a surge in demand for its laser prototyping systems from a diverse range of industries, including aerospace, automotive, medical, and consumer goods. This reflects the growing recognition of the value that laser prototyping brings to the table in terms of innovation, efficiency, and quality. As the manufacturing industry continues to evolve, it is clear that laser prototyping will play a crucial role in shaping the future of product development and production.With a strong track record of delivering cutting-edge laser solutions and a commitment to empowering its customers with the latest technology, {} is well-positioned to lead the charge in the widespread adoption of laser prototyping. The company's dedication to pushing the boundaries of what is possible with laser technology, coupled with its focus on customer satisfaction, has positioned it as a trusted partner for companies looking to harness the power of laser prototyping to gain a competitive edge in their respective industries.In conclusion, laser prototyping technology is a game-changer for the manufacturing industry, offering unparalleled speed, precision, and flexibility in the production of prototypes and production parts. With {} leading the charge in the development and implementation of advanced laser prototyping systems, the future of manufacturing looks brighter than ever. As companies continue to embrace this revolutionary technology, the possibilities for innovation and success are endless.

High-Quality CNC Turned Components for Precision Engineering

[Company Name], a leading manufacturer of precision machined components, announced the launch of a new line of CNC turned components. The company, known for its high-quality products and innovative solutions, has expanded its offerings to meet the growing demand for precision components in various industries.The new line of CNC turned components is manufactured using state-of-the-art machinery and advanced technologies. This allows for the production of complex and intricate components with tight tolerances and high accuracy. The components are designed to meet the specific requirements of customers in industries such as automotive, aerospace, medical, and electronics.With a focus on precision and quality, [Company Name] has invested in the latest CNC turning technology to ensure that the components meet the highest standards. The company's team of skilled engineers and technicians work closely with customers to understand their needs and provide custom solutions that meet their exact specifications.“We are thrilled to announce the launch of our new line of CNC turned components,” said [Spokesperson Name], CEO of [Company Name]. “With the increasing demand for precision components in various industries, we saw an opportunity to expand our product offerings and provide our customers with high-quality solutions that meet their specific needs.”[Company Name] has a strong track record of delivering precision components that meet and exceed the expectations of its customers. The company's commitment to quality and continuous improvement has earned it a reputation as a trusted partner for precision machining needs.In addition to the new line of CNC turned components, [Company Name] offers a wide range of services including CNC milling, turning, grinding, and assembly. The company's capabilities allow it to handle projects of all sizes and complexities, from prototyping to high-volume production.“We understand the importance of precision and accuracy in the manufacturing process, which is why we have invested in the latest technologies and equipment to ensure that we deliver components that meet the highest standards,” said [Spokesperson Name]. “Our team is dedicated to providing our customers with the best possible solutions to meet their needs, and we are excited to expand our offerings with the new line of CNC turned components.”With the launch of the new line of CNC turned components, [Company Name] aims to strengthen its position as a leading provider of precision machined components. The company's commitment to quality, innovation, and customer satisfaction sets it apart in the industry and positions it for continued success.As the demand for precision components continues to grow across various industries, [Company Name] is well-positioned to meet the needs of its customers with its new line of CNC turned components. The company's dedication to excellence and customer satisfaction ensures that it will remain a trusted partner for precision machining needs.[Company Name] invites customers to learn more about its new line of CNC turned components and explore the possibilities for custom solutions that meet their specific requirements. With its focus on quality, precision, and innovation, the company is poised to lead the way in providing high-quality machining solutions for various industries.