Silicone Rubber Seal Auto Part for Multi Pin Connectors

By:Admin

The Multi Pin Connector Silicone Rubber Seal Auto Part is a vital component in automotive electrical systems, as it helps to prevent moisture, dust, and other contaminants from infiltrating the connector. This is particularly important in modern vehicles, which are equipped with a wide range of electronic components that must remain operational in various environmental conditions.

[Company Name] has leveraged its extensive experience and expertise in the automotive industry to develop a durable and reliable silicone rubber seal that meets the stringent requirements of automotive manufacturers and aftermarket suppliers. The company's commitment to quality and innovation is evident in this new product, which is designed to withstand the harsh conditions of the automotive environment and provide long-lasting protection for multi pin connectors.

"We are excited to introduce our Multi Pin Connector Silicone Rubber Seal Auto Part to the market," said [Spokesperson Name], [Title] at [Company Name]. "This product is the result of our dedication to engineering excellence and our focus on meeting the evolving needs of the automotive industry. We believe that it will be a valuable addition to our portfolio of automotive components and will help our customers deliver reliable and durable electronic systems in their vehicles."

In addition to its superior protective properties, the Multi Pin Connector Silicone Rubber Seal Auto Part also offers ease of installation, thanks to its flexible and adaptable design. This makes it an ideal solution for automotive manufacturers, as well as aftermarket suppliers and repair shops that need to replace or upgrade multi pin connector seals in existing vehicles.

As part of its commitment to customer satisfaction, [Company Name] ensures that the Multi Pin Connector Silicone Rubber Seal Auto Part meets the highest quality standards. The product undergoes rigorous testing and inspection processes to validate its performance and durability, giving customers the confidence that it will deliver the expected results in demanding automotive applications.

Furthermore, [Company Name] provides comprehensive technical support and assistance to its customers, helping them to integrate the Multi Pin Connector Silicone Rubber Seal Auto Part into their products or services. The company's team of automotive experts is available to collaborate with customers on custom solutions and to address specific challenges related to multi pin connector sealing in electronic systems.

With the release of the Multi Pin Connector Silicone Rubber Seal Auto Part, [Company Name] reaffirms its position as a trusted partner for automotive manufacturers and aftermarket suppliers seeking high-quality components and innovative solutions. The company's dedication to excellence and its relentless pursuit of technological advancement continue to drive its success in the competitive automotive industry.

In conclusion, the introduction of the Multi Pin Connector Silicone Rubber Seal Auto Part highlights [Company Name]'s commitment to delivering cutting-edge solutions that address the evolving needs of the automotive industry. This innovative product is poised to make a significant impact on the performance and reliability of electronic systems in vehicles, providing customers with a durable and effective sealing solution for multi pin connectors. [Company Name]'s expertise, dedication to quality, and customer-centric approach position it as a leading provider of automotive components, capable of meeting the most demanding requirements of its customers.

Company News & Blog

Rapid Prototyping Mold: A Guide to Fast Mold Creation for Manufacturing

Rapid Prototyping Mold: A Game-Changer in ManufacturingIn today's fast-paced and competitive manufacturing industry, the ability to quickly and efficiently produce high-quality molds is essential. This is where rapid prototyping molds come into play, revolutionizing the way products are designed and manufactured. With their speed, precision, and cost-effectiveness, rapid prototyping molds are changing the game for businesses across various sectors.One company at the forefront of this game-changing technology is [Company Name]. With over [number of years] of experience in the manufacturing industry, [Company Name] has established itself as a leading provider of rapid prototyping molds, catering to the needs of businesses looking to streamline their production processes and bring innovative products to market faster than ever before.Rapid prototyping molds, also known as 3D printing molds, are created using advanced additive manufacturing techniques. This allows for the rapid production of custom molds with intricate designs and complex geometries that traditional manufacturing methods struggle to achieve. The result is a significant reduction in lead times and costs, as well as the ability to iterate and refine designs more quickly and with greater accuracy.[Company Name] has invested heavily in state-of-the-art 3D printing technology, enabling them to offer their clients a wide range of rapid prototyping mold solutions. From small-scale molds for plastic injection molding to larger molds for metal casting, [Company Name] can meet the diverse needs of businesses operating in various industries, such as automotive, aerospace, consumer goods, and more.One of the key advantages of rapid prototyping molds is their ability to accelerate the product development cycle. By quickly producing molds for prototype parts, businesses can test and validate their designs much earlier in the process, leading to faster iterations and ultimately, a shorter time to market. This is particularly beneficial for companies looking to stay ahead of the competition and capitalize on emerging opportunities in their respective markets.Furthermore, rapid prototyping molds offer unparalleled design freedom. Unlike traditional molds that are limited by manufacturing constraints, 3D printing molds allow for highly complex and intricate designs to be realized with ease. This opens up new possibilities for product innovation and customization, giving businesses the flexibility to create unique and highly functional products that stand out in the marketplace.In addition to their speed and flexibility, rapid prototyping molds also offer cost advantages. With traditional mold-making methods, the cost of creating custom molds can be prohibitively high, especially for small production runs. Rapid prototyping molds, on the other hand, significantly reduce the upfront costs associated with mold production, making it more accessible for businesses of all sizes to bring their ideas to life.The benefits of rapid prototyping molds are clear, and businesses that embrace this technology are poised to gain a competitive edge in the market. By partnering with a trusted and experienced provider like [Company Name], businesses can harness the power of rapid prototyping molds to accelerate their product development, reduce costs, and ultimately, drive innovation in their respective industries.Looking ahead, the potential for rapid prototyping molds to transform the manufacturing landscape is immense. As the technology continues to evolve and improve, businesses will have even greater opportunities to push the boundaries of what's possible in product design and production. With [Company Name] leading the way in this exciting field, the future of manufacturing looks brighter than ever.

High-Quality Round Rubber Gaskets Seals for Various Applications

[Company Introduction]With a history dating back to 1960, we are a leading manufacturer and supplier of high-quality rubber gaskets and seals to a wide range of industries such as automotive, aerospace, pharmaceutical, and industrial manufacturing. Our commitment to excellence and constant innovation has solidified our reputation as a trusted partner in providing sealing solutions that meet the rigorous demands of our customers.Our state-of-the-art manufacturing facility is equipped with the latest technology and machinery to ensure precision and consistency in the production of our rubber gaskets and seals. We take pride in our skilled team of engineers and technicians who work tirelessly to develop and improve our products, always striving to stay ahead of industry standards.In line with our dedication to quality, we adhere to strict quality control measures at every stage of the manufacturing process, from sourcing raw materials to the final inspection of finished products. Our ISO 9001 certification is a testament to our unwavering commitment to delivering products of the highest standard to our customers.[News Content]The demand for high-performance rubber gaskets and seals continues to grow across various industries, and we are proud to announce our latest innovation in this space. Our newly developed Round Rubber Gaskets Seals are set to revolutionize the sealing industry with their exceptional performance and durability.Designed to meet the stringent requirements of diverse applications, our Round Rubber Gaskets Seals boast a range of features that set them apart from conventional sealing solutions. The use of premium quality rubber compounds ensures excellent resistance to temperature, pressure, and chemical exposure, making them suitable for use in the most demanding environments.One of the key highlights of our Round Rubber Gaskets Seals is their superior compression set properties, which enables them to maintain a tight and reliable seal over an extended period. This makes them ideal for sealing applications that require long-term performance and minimal maintenance. Additionally, the round design of these gaskets and seals ensures uniform contact pressure, further enhancing their sealing efficiency.The versatility of our Round Rubber Gaskets Seals is another compelling aspect, as they can be customized to suit specific customer requirements. Whether it's a unique size, shape, or material specification, our team of experts is capable of tailoring these sealing solutions to meet the precise needs of our customers, providing them with a truly bespoke sealing solution.Furthermore, sustainability is a key consideration in our product development, and our Round Rubber Gaskets Seals are manufactured with eco-friendly processes and materials. By prioritizing environmental responsibility, we aim to provide our customers with sealing solutions that not only deliver performance but also contribute to a more sustainable future.In addition to the superior performance of our Round Rubber Gaskets Seals, customers can also benefit from our exceptional customer service and technical support. Our team of experienced professionals is always ready to provide assistance and guidance, ensuring that our customers have a seamless experience from product selection to post-installation support.As we introduce our Round Rubber Gaskets Seals to the market, we are confident that they will set a new benchmark for sealing solutions and reinforce our position as a leader in the industry. With their outstanding performance, versatility, and eco-friendly attributes, our Round Rubber Gaskets Seals are poised to meet the evolving needs of our customers and contribute to the advancement of various industries.

High-quality Precision Brass Parts Welding and Bending Services Available

Precision Manufacturing Company, a leading provider of precision brass parts welding and bending services, has recently announced the expansion of its capabilities to meet the growing demands of its customers.The company has been in the precision manufacturing industry for over 20 years, specializing in the production of high-quality brass parts for various industries including automotive, aerospace, electronics, and medical. With a commitment to excellence and continuous improvement, Precision Manufacturing Company has earned a reputation for delivering exceptional products and services to its clients.In response to the increasing demand for precision brass parts welding and bending services, the company has invested in state-of-the-art equipment and technology to enhance its manufacturing capabilities. This investment has enabled Precision Manufacturing Company to offer a wider range of services to its customers, including precision TIG welding, robotic welding, and CNC bending.The expansion of the company's capabilities is in line with its dedication to providing comprehensive solutions to its customers' manufacturing needs. By offering precision brass parts welding and bending services, Precision Manufacturing Company aims to become a one-stop shop for all precision manufacturing requirements, from design and prototyping to production and assembly."We are excited to announce the expansion of our capabilities to include precision brass parts welding and bending services," said the CEO of Precision Manufacturing Company. "This expansion is a testament to our commitment to meeting the evolving needs of our customers and providing them with the highest quality products and services."With the addition of precision brass parts welding and bending services, Precision Manufacturing Company can now offer a complete range of manufacturing solutions to its customers. Whether they require small or large volume production, complex or simple parts, the company's expanded capabilities allow it to meet a wide variety of requirements with precision and efficiency.The company's team of highly skilled engineers and technicians are equipped with the expertise and experience to handle the most challenging welding and bending projects. Whether it's creating intricate bends in brass tubing or welding complex assemblies, Precision Manufacturing Company can deliver precise and reliable results that meet the highest standards of quality and craftsmanship.In addition to its expanded capabilities, Precision Manufacturing Company remains committed to upholding the highest standards of quality and safety in its manufacturing processes. The company follows strict quality control measures to ensure that every part produced meets the exact specifications and requirements of its customers. Furthermore, it complies with industry regulations and standards to ensure the safety and integrity of its products.The expansion of Precision Manufacturing Company's capabilities comes as a response to the growing demand for precision manufacturing services in the industry. By offering a comprehensive range of services, the company aims to strengthen its position as a trusted partner for its customers, providing them with the expertise, resources, and support they need to bring their products to market.As the company continues to grow and expand its capabilities, it remains committed to its core values of innovation, quality, and customer satisfaction. Precision Manufacturing Company sees its expansion as a step forward in its journey to becoming a global leader in precision manufacturing, providing reliable and comprehensive solutions to its customers' most demanding requirements.With its expanded capabilities in precision brass parts welding and bending services, Precision Manufacturing Company is poised to meet the evolving needs of its customers and continue its legacy of excellence in the precision manufacturing industry.

High-Quality Plastic Molding Services for Precision Engineering Needs

Precision Plastic Molding provides high-quality plastic injection molding solutions for a wide range of industries. With advanced technology and a team of experienced professionals, the company is able to produce precision parts that meet the specific needs of their clients. Their dedication to quality and customer satisfaction has helped them to become a leader in the plastic molding industry.The company specializes in custom plastic injection molding, offering services such as design assistance, prototyping, and production. They work closely with their clients to understand their requirements and develop a customized solution that meets their needs. Whether it's a small batch of parts or a large production run, Precision Plastic Molding has the capabilities to deliver high-quality results.One of the key advantages of working with Precision Plastic Molding is their ability to handle complex projects. They have the expertise and technology to produce intricate parts with tight tolerances, ensuring that the final products meet the exact specifications of their clients. This level of precision and attention to detail has earned them a reputation for excellence in the industry.In addition to their technical capabilities, Precision Plastic Molding also places a strong emphasis on quality control and assurance. They have rigorous processes in place to ensure that every part they produce meets the highest standards of quality. This commitment to excellence has helped them to build long-term relationships with their clients, who trust them to deliver reliable and consistent results.Precision Plastic Molding serves a diverse range of industries, including automotive, medical, consumer electronics, and more. They have the flexibility to work with a variety of materials, including thermoplastics, thermosets, and elastomers, allowing them to meet the needs of clients with different material requirements. This versatility has made them a valuable partner for companies across various sectors.In addition to their technical expertise, Precision Plastic Molding is known for their collaborative approach to project management. They work closely with their clients throughout the entire process, from initial design concept to final production, to ensure that the end result meets their expectations. This level of engagement and communication has helped them to build strong and lasting partnerships with their clients.The company's commitment to innovation is reflected in their investment in advanced technology and equipment. They continue to explore new solutions and techniques to improve their processes and expand their capabilities. This forward-thinking approach has helped them to stay ahead of the curve and remain competitive in the rapidly evolving plastic molding industry.Furthermore, Precision Plastic Molding is dedicated to sustainability and environmental responsibility. They prioritize the use of eco-friendly materials and processes, minimizing waste and reducing their environmental impact. This commitment to sustainability has become increasingly important to their clients, who seek partners that share their values and priorities.Overall, Precision Plastic Molding is a trusted and reliable partner for companies in need of high-quality plastic injection molding solutions. With their technical expertise, commitment to quality, and focus on collaboration and sustainability, they have established themselves as a leader in the industry. Their continued investment in innovation and dedication to customer satisfaction positions them for continued success in the years to come.

Guide to Insert Moulding: What You Need to Know

[Company Name] introduces new Insert Moulding technology for enhanced product quality[Company Name], a leading innovator in the manufacturing industry, has announced the introduction of a new Insert Moulding technology that is set to revolutionize the production of plastic and metal components. The new technology is designed to improve product quality and reduce production costs, providing a competitive edge in the market.Insert Moulding is a process in which a metal or plastic insert is placed into the mould before the material is injected, creating a strong and seamless bond between the insert and the surrounding material. This process is widely used in the manufacturing of electronics, automotive parts, medical devices, and consumer products.The introduction of this new technology by [Company Name] is a testament to their commitment to innovation and continuous improvement. With over three decades of experience in the industry, [Company Name] has a proven track record of delivering high-quality products and cutting-edge solutions to their customers.The new Insert Moulding technology is expected to bring several benefits to the company and its customers. By integrating inserts directly into the mould during the manufacturing process, [Company Name] will be able to produce components that are more durable, reliable, and cost-effective. This will in turn provide added value to their customers, as they will benefit from improved product performance and longevity.In addition to improving product quality, the new technology will also streamline the production process, reducing lead times and overall production costs. This will enable [Company Name] to offer competitive pricing and faster turnaround times to their customers, further enhancing their position in the market.“We are thrilled to introduce the new Insert Moulding technology to our production process,” said [Spokesperson Name], [Title] at [Company Name]. “This innovation represents a significant milestone for our company and our customers. We are confident that it will have a positive impact on our product quality, production efficiency, and overall customer satisfaction.”The introduction of Insert Moulding technology is also in line with [Company Name]’s commitment to sustainability and environmental responsibility. By streamlining the production process and reducing material waste, the company aims to minimize its environmental footprint and contribute to a more sustainable future.As a company that is always at the forefront of technological advancement, [Company Name] continues to invest in research and development to stay ahead of the curve. The introduction of Insert Moulding technology is just one example of their dedication to innovation and their constant pursuit of excellence in manufacturing.With the new technology now being integrated into their production process, [Company Name] is well-positioned to meet the evolving needs of their customers and drive growth in their respective markets. By offering enhanced product quality, improved production efficiency, and a lower environmental impact, the company is poised to set new standards in the manufacturing industry.As [Company Name] continues to expand its capabilities and offerings, the introduction of Insert Moulding technology marks a significant milestone in their journey towards becoming a leader in the industry. With a focus on innovation, quality, and customer satisfaction, the company is well-equipped to meet the demands of the market and deliver exceptional value to its customers.

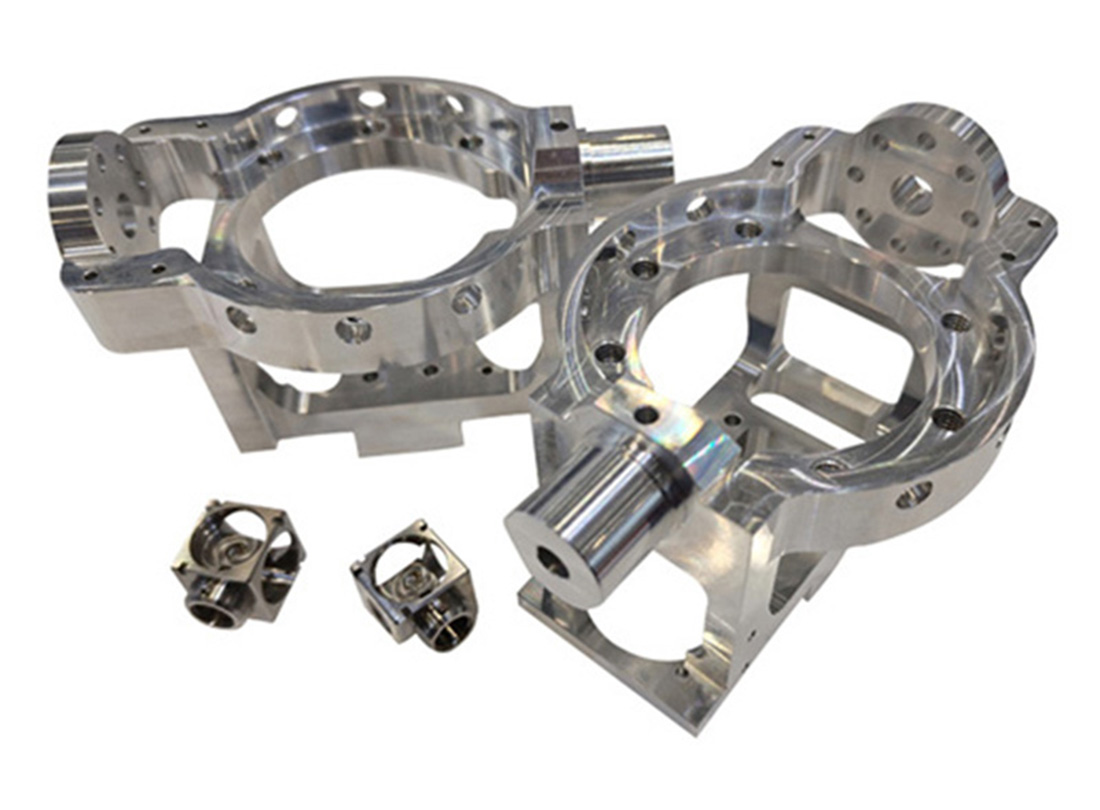

High-quality CNC Machining Parts for Precision Engineering

Precision CNC Machining Parts has emerged as a leading provider of high-quality, custom precision machining solutions for a wide range of industries. With expertise in CNC machining, milling, and turning, the company has built a reputation for delivering superior products and services to its clients.Established in 2005, Precision CNC Machining Parts has grown from a small machine shop to a state-of-the-art manufacturing facility, equipped with the latest technology and a team of skilled professionals. The company's commitment to precision, quality, and customer satisfaction has set it apart in the industry.Precision CNC Machining Parts specializes in producing complex and intricate machined parts for industries such as aerospace, automotive, medical, and defense. The company's advanced CNC machines are capable of producing parts with tight tolerances and intricate geometries, meeting the most demanding specifications.In addition to CNC machining, the company offers a range of secondary processes, including plating, anodizing, and assembly, to provide complete turnkey solutions for its customers. With a focus on continuous improvement and innovation, Precision CNC Machining Parts is constantly investing in new technology and training to ensure it stays at the forefront of the industry.The company's dedication to quality is reflected in its ISO 9001 certification, which demonstrates its commitment to meeting and exceeding the highest standards of quality and consistency. This certification ensures that all parts manufactured by Precision CNC Machining Parts adhere to strict quality control processes, from initial design to final inspection.One of the key differentiators of Precision CNC Machining Parts is its ability to work closely with customers to understand their unique needs and provide tailored solutions. Whether it's a prototype, a small production run, or a large-scale manufacturing project, the company's team of engineers and machinists are dedicated to delivering precision parts that meet or exceed customer expectations.Precision CNC Machining Parts prides itself on its fast turnaround times and competitive pricing, making it a trusted partner for companies looking for reliable and cost-effective precision machining solutions. With a focus on customer satisfaction and long-term partnerships, the company has built a solid reputation for delivering exceptional value to its clients.As the manufacturing industry continues to evolve, Precision CNC Machining Parts remains committed to staying ahead of the curve and meeting the evolving needs of its customers. Through ongoing investment in technology, training, and process improvement, the company is well-positioned to continue its growth and success in the industry.Whether it's a complex aerospace component, a critical medical device, or a precision automotive part, Precision CNC Machining Parts has the expertise, capabilities, and dedication to deliver the highest quality precision machined parts to its customers.As the company looks to the future, it remains focused on its core values of precision, quality, and customer satisfaction, positioning itself as a trusted partner for companies seeking reliable and cost-effective precision machining solutions. With a track record of success and a commitment to continuous improvement, Precision CNC Machining Parts is poised to remain at the forefront of the industry for years to come.

Durable Rubber Gasket for Industrial Use: A Comprehensive Guide

Square Rubber Gasket, a leading manufacturer in the rubber gasket industry, has recently unveiled its latest product designed to meet the ever-growing demand for high-quality and reliable gaskets in various industrial applications. With a history of excellence and innovation, Square Rubber Gasket has set itself apart as a trusted source for superior rubber gaskets.Established in [year], Square Rubber Gasket has built a solid reputation for delivering top-notch gaskets that excel in performance, durability, and effectiveness. The company is committed to utilizing advanced manufacturing techniques and high-quality materials to produce gaskets that meet or exceed industry standards. With a focus on customer satisfaction and engineering excellence, Square Rubber Gasket has become a preferred choice for businesses seeking reliable sealing solutions.The newly launched square rubber gasket is the latest addition to Square Rubber Gasket's extensive product line. Engineered to precise specifications, this gasket is designed to provide exceptional sealing performance in a wide range of applications. The square shape of the gasket offers unique advantages, including enhanced stability and a tight seal, making it an ideal choice for various industrial equipment and machinery."We are thrilled to introduce our latest square rubber gasket to the market," said [spokesperson]. "This new product showcases our dedication to innovation and our commitment to meeting the evolving needs of our customers. We are confident that this gasket will deliver outstanding performance and reliability, further solidifying our position as a leader in the industry."The square rubber gasket is manufactured using advanced rubber compounds that offer superior resilience, resistance to heat and chemicals, and long-lasting durability. These properties make the gasket suitable for use in demanding environments where reliable sealing is crucial. Additionally, the square shape of the gasket provides enhanced stability and uniform compression, ensuring a tight and secure seal.One of the key advantages of the square rubber gasket is its versatility. It can be used across various industries, such as automotive, aerospace, marine, manufacturing, and many others. Whether it is sealing components in heavy machinery or providing insulation in electrical enclosures, the square rubber gasket offers a reliable solution for a wide range of applications.Square Rubber Gasket's commitment to quality and excellence extends beyond its products. The company's dedication to providing exceptional customer service and technical support has earned it a loyal and satisfied customer base. With a team of experienced engineers and industry experts, Square Rubber Gasket works closely with its clients to understand their specific sealing requirements and provide customized solutions that meet their needs.As a responsible and environmentally conscious manufacturer, Square Rubber Gasket takes great care to ensure its production processes are sustainable and eco-friendly. The company complies with all relevant regulations and standards, and it continuously seeks to minimize its environmental impact through efficient use of resources and waste reduction.In conclusion, Square Rubber Gasket's latest square rubber gasket represents a significant advancement in sealing technology. With its precision engineering, exceptional performance, and versatility, this gasket is poised to set new standards in the industry. As Square Rubber Gasket continues to push the boundaries of innovation and quality, it remains a trusted partner for businesses seeking reliable sealing solutions. With its unwavering commitment to excellence and customer satisfaction, Square Rubber Gasket is set to maintain its position as a leader in the rubber gasket industry.

Benefits of Prototype Plastic Molding for your Business

Prototype Plastic Molding, a leading provider of custom plastic injection molding solutions, has recently expanded their services to better serve the growing demand for high-quality plastic parts in various industries. With over 20 years of experience in the industry, Prototype Plastic Molding has become a trusted partner for companies looking for reliable and cost-effective plastic molding solutions.The company is known for its state-of-the-art facilities, highly skilled team of engineers and technicians, and commitment to delivering top-notch products to their clients. They offer a wide range of services including product design and development, mold making, injection molding, assembly, and packaging. Their expertise in the field has allowed them to work with clients in industries such as automotive, medical, consumer goods, and more.One of the key factors that set Prototype Plastic Molding apart from their competitors is their dedication to using the latest technology and equipment in their manufacturing processes. This allows them to produce parts with high precision, consistency, and efficiency, while also reducing lead times and overall costs for their clients.In response to the increasing demand for sustainable manufacturing practices, Prototype Plastic Molding has also made significant investments in environmentally friendly initiatives. They have implemented processes and materials to reduce waste, minimize energy consumption, and decrease their carbon footprint. This commitment to sustainability not only benefits the environment but also positions them as a forward-thinking and socially responsible partner for their clients.As part of their expansion efforts, Prototype Plastic Molding has recently added new injection molding machines to their production line. These machines are equipped with the latest technology to improve efficiency and capacity, allowing the company to take on larger and more complex projects. Additionally, they have expanded their workforce to accommodate the growing demand for their services, hiring new talent with expertise in various aspects of plastic molding.The company's dedication to continuous improvement and innovation has earned them a solid reputation in the industry. They are committed to staying ahead of the curve and offering cutting-edge solutions to their clients. This dedication has led to long-standing partnerships with many of their clients, who rely on Prototype Plastic Molding for their expertise and reliability.In addition to their expansion efforts, Prototype Plastic Molding also remains focused on providing exceptional customer service. They understand the importance of clear communication, attention to detail, and on-time delivery for their clients. Their team works closely with each client to understand their specific needs and develop customized solutions that meet their requirements.Looking ahead, Prototype Plastic Molding is poised for continued growth and success in the industry. They are committed to staying at the forefront of plastic molding technology, expanding their capabilities, and providing even greater value to their clients. With their dedication to quality, innovation, and customer satisfaction, Prototype Plastic Molding is well-positioned to remain a leader in the custom plastic injection molding industry for years to come.

How Insert Moulding Can Enhance Your Home Decor

Insert Moulding, also known as overmoulding, is a process in which a plastic component is moulded onto a pre-formed part, usually made of metal. This process is mainly used in the manufacturing of electronic devices, automobile components, medical devices, and consumer products.The company Insert Moulding, based in the United States, specializes in providing custom insert moulding solutions for a wide range of industries. With over 20 years of experience in the industry, Insert Moulding has established itself as a leading provider of high-quality insert moulding services.The company's state-of-the-art facilities and advanced technology allow them to produce complex and precision moulded parts with exceptional quality and efficiency. Insert Moulding's team of expert engineers and technicians work closely with clients to design and develop custom insert moulding solutions that meet their specific requirements.Insert Moulding offers a wide range of materials for insert moulding, including thermoplastics, thermosets, and elastomers. They also provide a variety of finishing options, such as painting, plating, and custom colour matching, to ensure that the final product meets the desired aesthetic and functional requirements.In addition to insert moulding, the company also offers value-added services such as assembly, packaging, and logistics management. This comprehensive approach allows Insert Moulding to provide clients with turnkey solutions for their insert moulding needs, saving them time and resources.Insert Moulding is committed to upholding the highest standards of quality and compliance in their manufacturing processes. They are ISO 9001 certified and adhere to stringent quality control measures to ensure that every product meets the highest industry standards.Furthermore, Insert Moulding is dedicated to sustainability and environmental responsibility. They prioritize the use of eco-friendly materials and processes, and strive to minimize their environmental impact throughout the production and supply chain.The company's commitment to innovation and continuous improvement has positioned them as a trusted partner for businesses seeking reliable and cost-effective insert moulding solutions. Their dedication to customer satisfaction and technical expertise has earned them a solid reputation in the industry.Insert Moulding's success is also attributed to their focus on fostering strong client relationships and providing exceptional customer service. They work closely with clients throughout every stage of the project, from concept and design to production and delivery, to ensure that their needs are met and expectations exceeded.In conclusion, Insert Moulding has solidified its position as a leading provider of custom insert moulding solutions, offering a comprehensive range of services, advanced technology, and a dedication to quality and customer satisfaction. With a proven track record of success and a commitment to innovation, Insert Moulding is well-equipped to meet the insert moulding needs of businesses across various industries.

Plastic Machining Prototype: A Complete Guide

CNC Plastic Machining Prototype: Revolutionizing the Manufacturing IndustryIn a world where precision and efficiency are key components for success in the manufacturing industry, the use of advanced technologies such as CNC plastic machining prototypes has become increasingly important. With the ability to create high-quality, precise plastic components with unmatched speed and accuracy, this groundbreaking technology has the potential to revolutionize the way products are developed and manufactured.The use of CNC (Computer Numerical Control) technology in plastic machining has significantly improved the manufacturing process. This revolutionary technology allows for the automated control of machining tools using a computer program, resulting in highly precise and consistent plastic components. By leveraging the power of CNC plastic machining prototypes, companies can significantly reduce production time and costs, while delivering top-quality products to their customers.In the midst of this technological revolution, one company stands out as a leader in the field of CNC plastic machining prototypes. {Company} is a renowned manufacturer and supplier of cutting-edge CNC plastic machining solutions. With a strong focus on innovation and cutting-edge technology, {Company} has established itself as a trusted partner for businesses seeking high-quality plastic machining prototypes.{Company} has consistently demonstrated a commitment to excellence and innovation in the field of CNC plastic machining prototypes. Their state-of-the-art manufacturing facility is equipped with the latest CNC machines, allowing them to produce top-quality plastic components with unmatched precision and accuracy. Coupled with a team of highly skilled engineers and technicians, {Company} has the expertise and resources to meet the evolving needs of the manufacturing industry.The use of CNC plastic machining prototypes from {Company} has had a profound impact on the manufacturing industry. By leveraging this advanced technology, companies can accelerate the product development process, reduce production lead times, and minimize material wastage. Additionally, the high precision and repeatability of CNC plastic machining prototypes ensure that companies can consistently deliver products that meet the highest quality standards.{Company}'s commitment to delivering excellence extends beyond just the technology. With a strong emphasis on customer satisfaction, {Company} works closely with businesses to understand their specific requirements and deliver tailored solutions that meet their needs. The company's dedication to customer service and support has further solidified its reputation as a trusted partner for businesses seeking reliable and efficient CNC plastic machining prototypes.The impact of CNC plastic machining prototypes goes beyond just the manufacturing process. By streamlining production and improving efficiency, companies can reduce their environmental footprint and contribute to a more sustainable future. The ability to produce high-quality plastic components with minimal material wastage has the potential to revolutionize the way products are manufactured, paving the way for a more sustainable and environmentally friendly manufacturing industry.As the manufacturing industry continues to evolve, the demand for high-quality, precision plastic components will only grow. With the versatility and efficiency of CNC plastic machining prototypes, companies can stay ahead of the curve and meet the demands of an ever-changing market. {Company} remains at the forefront of this technological revolution, continuously pushing the boundaries of innovation and excellence in CNC plastic machining prototypes.In conclusion, the use of CNC plastic machining prototypes has the potential to revolutionize the manufacturing industry. With its unmatched precision, speed, and efficiency, this groundbreaking technology is poised to transform the way products are developed and manufactured. {Company} continues to lead the charge in this technological revolution, delivering top-quality CNC plastic machining solutions that meet the evolving needs of the industry. As businesses continue to seek innovative solutions for their manufacturing needs, the use of CNC plastic machining prototypes from {Company} will undoubtedly play a crucial role in shaping the future of the industry.