Top Plastic Prototyping Techniques for Product Development

By:Admin

In a world where innovation is the key to success, {Company Name} has established itself as a leader in the field of plastic prototyping. With a strong emphasis on research and development, the company has continuously pushed the boundaries of what is possible in the world of plastic manufacturing.

{Company Name} has invested heavily in cutting-edge technology and state-of-the-art equipment to stay at the forefront of the industry. Through their commitment to innovation, they have been able to provide their customers with high-quality plastic prototypes that are both functional and aesthetically pleasing.

The company's dedication to excellence is evident in their approach to plastic prototyping. They have a team of highly skilled engineers and designers who work tirelessly to bring their customers' ideas to life. By utilizing the latest 3D printing and rapid prototyping technologies, {Company Name} has been able to produce prototypes with unmatched precision and speed.

One of the key advantages of plastic prototyping is the ability to quickly and cost-effectively test new product designs. This allows companies to identify any potential issues early in the development process, saving both time and money in the long run. {Company Name} has been a pioneer in this area, offering their customers a streamlined and efficient prototyping process that accelerates their product development cycle.

Furthermore, the company's commitment to sustainability sets them apart from their competitors. {Company Name} is dedicated to reducing their environmental impact through the use of eco-friendly materials and sustainable production processes. This not only benefits the planet but also provides their customers with a competitive edge by appealing to environmentally conscious consumers.

In addition to their advanced prototyping capabilities, {Company Name} offers a wide range of plastic manufacturing services to support their customers from concept to production. Their comprehensive suite of services includes mold design and fabrication, injection molding, and quality assurance.

The company's dedication to excellence and customer satisfaction has earned them a strong reputation in the industry. They have successfully served a diverse range of industries, including automotive, consumer electronics, medical devices, and more. Their ability to adapt to the unique needs of each customer has solidified their position as a trusted partner in the plastic manufacturing industry.

Moving forward, {Company Name} remains committed to pushing the boundaries of what is possible in plastic prototyping. Their ongoing investment in research and development will ensure that they remain at the forefront of innovation for years to come. By continuing to provide their customers with exceptional service and cutting-edge solutions, {Company Name} is set to maintain its reputation as a leader in the industry.

In conclusion, {Company Name} has established itself as a trailblazer in the field of plastic prototyping. Through their dedication to innovation, sustainability, and customer satisfaction, they have been able to provide their customers with the highest quality prototypes and manufacturing services. With a commitment to pushing the boundaries of what is possible, {Company Name} is poised to continue leading the way in plastic prototyping for years to come.

Company News & Blog

High-Quality Silicone Parts Moulding Services for Various Industries

Silicone Parts Moulding: The Future of ManufacturingSilicone parts moulding has become the forefront of the manufacturing industry due to its versatility, durability, and cost-effectiveness. This manufacturing process involves creating intricate and complex parts using a silicone moulding material. These silicone parts can be used in a wide range of industries, including automotive, medical, aerospace, and consumer goods.One of the leading companies in the silicone parts moulding industry is {} {Company}. With over 20 years of experience in the field, {Company} has established itself as a pioneer in silicone parts manufacturing. The company's commitment to innovation and excellence has earned them a reputation for delivering high-quality silicone parts to clients worldwide.{Company} specializes in custom silicone parts moulding, offering a wide range of services to meet the unique needs of their customers. From design and prototyping to production and assembly, {Company} has the capabilities to provide end-to-end solutions for silicone parts manufacturing. Their state-of-the-art facilities and advanced technologies allow them to produce complex silicone parts with precision and efficiency.The key to {Company}'s success lies in their expertise in silicone materials and moulding processes. They understand the unique properties of silicone and can tailor their manufacturing processes to meet the specific requirements of their customers. Whether it's high-temperature resistance, chemical compatibility, or superior flexibility, {Company} can create silicone parts that meet the most demanding specifications.In addition to their technical expertise, {Company} is also known for their commitment to quality and customer satisfaction. They adhere to strict quality control measures throughout the manufacturing process to ensure that every silicone part meets the highest standards. Their dedication to excellence has earned them the trust of leading companies in various industries, making them a preferred partner for silicone parts moulding.One of the key advantages of silicone parts moulding is its ability to create complex and intricate parts with precision and consistency. {Company} leverages advanced moulding technologies to produce silicone parts with tight tolerances, intricate geometries, and fine details. This level of precision allows for the creation of custom silicone parts that meet the exacting requirements of their customers.Another benefit of silicone parts moulding is its cost-effectiveness. Silicone is a highly durable and long-lasting material, making it an ideal choice for manufacturing parts that require longevity and reliability. Additionally, the moulding process allows for high-volume production with minimal waste, resulting in cost savings for both {Company} and their customers.Furthermore, silicone parts offer a wide range of performance benefits, including resistance to extreme temperatures, chemicals, and environmental conditions. This makes silicone parts suitable for a diverse range of applications, from automotive gaskets and seals to medical device components and aerospace parts. {Company} has the expertise to design and manufacture silicone parts that perform reliably in these demanding environments.Looking ahead, the future of silicone parts moulding looks bright, with {Company} leading the way in innovation and excellence. The company continues to invest in research and development to explore new materials and technologies that will further improve the capabilities of silicone parts manufacturing. By staying at the forefront of this rapidly evolving industry, {Company} is well-positioned to meet the evolving needs of their customers and drive the advancement of silicone parts moulding.In conclusion, silicone parts moulding has emerged as a game-changer in the manufacturing industry, offering a versatile, durable, and cost-effective solution for producing complex parts. {Company} stands at the forefront of this industry, with its expertise, commitment to quality, and advanced capabilities setting it apart as a leader in silicone parts manufacturing. With a focus on innovation and excellence, {Company} is poised to shape the future of silicone parts moulding and continue to deliver high-quality solutions to their customers worldwide.

High Precision CNC Machining Services for Your Business Needs

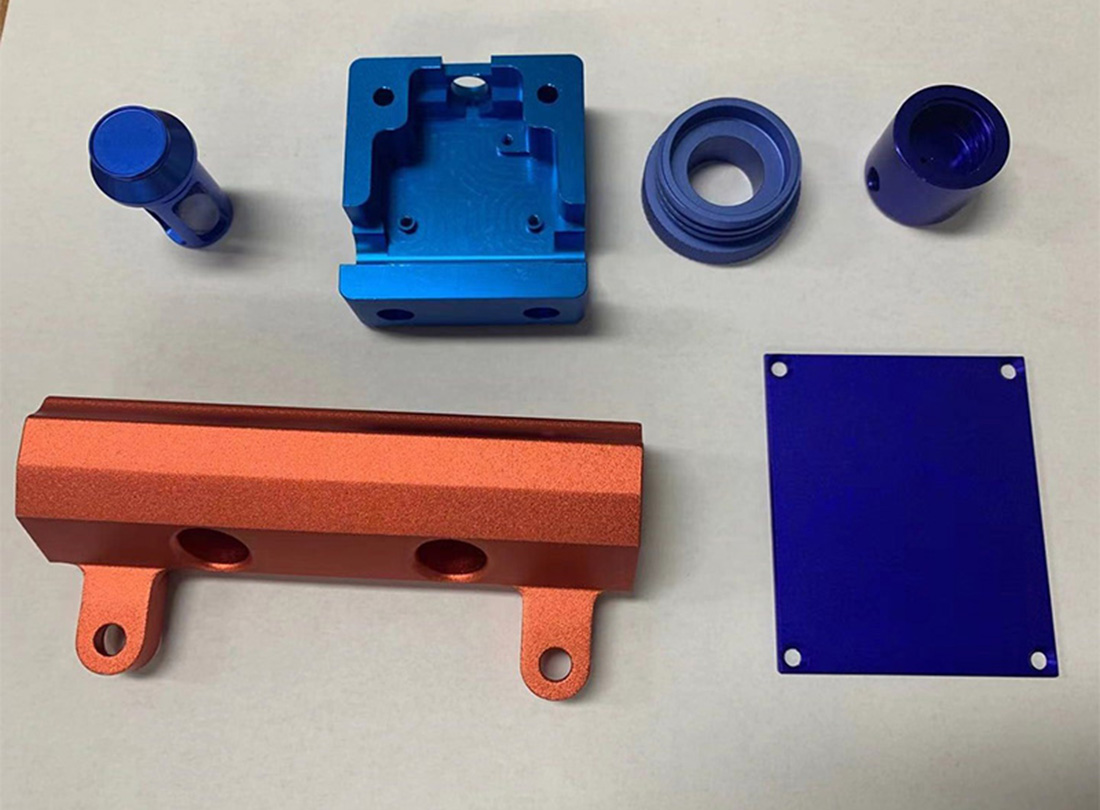

CNC Precision Manufacturing Company Leads the Industry with State-of-the-Art TechnologyIn the fast-paced world of manufacturing, precision is paramount. From small components to large-scale productions, precision in manufacturing is the key to success. This is where CNC Precision Manufacturing Company has set itself apart from the competition. With their cutting-edge technology and commitment to excellence, they have become a leading force in the industry.CNC Precision Manufacturing Company, based in (location), has been at the forefront of the manufacturing industry for over 20 years. Specializing in precision machining and fabrication, the company has built a reputation for delivering top-quality products to a wide range of industries, including aerospace, automotive, medical, and defense.The company's success can be attributed to its state-of-the-art facility, which is fully equipped with the latest CNC machines, robotic arms, and advanced software. This allows the team of highly skilled engineers and technicians to produce components with unparalleled accuracy and efficiency. The company's dedication to investing in cutting-edge technology has allowed them to stay ahead of the curve and meet the ever-changing demands of the market.One of the key factors that has set CNC Precision Manufacturing Company apart from its competitors is its commitment to innovation. The company constantly seeks new ways to improve its processes and enhance its capabilities. By investing in research and development, the company has been able to develop innovative solutions that have revolutionized the manufacturing process. This has allowed them to produce complex components with intricate designs and tight tolerances, giving them an edge in the market.Furthermore, CNC Precision Manufacturing Company has a strong emphasis on quality control. Every component goes through a rigorous inspection process to ensure that it meets the highest standards. This dedication to quality has earned the company numerous certifications and accolades, making it a trusted partner for companies that demand precision and reliability in their components.In addition to its technical capabilities, CNC Precision Manufacturing Company places a significant emphasis on customer satisfaction. The team works closely with its clients to understand their specific needs and requirements, offering personalized solutions that meet and exceed their expectations. This customer-centric approach has solidified the company's reputation as a reliable and trusted partner in the industry.CNC Precision Manufacturing Company's commitment to excellence has not gone unnoticed. The company has received numerous awards and recognition for its outstanding performance and contributions to the industry. With a strong track record of delivering exceptional products and services, the company continues to be a leading force in the manufacturing sector.Looking ahead, CNC Precision Manufacturing Company remains dedicated to pushing the boundaries of innovation in manufacturing. With a focus on continuous improvement and a forward-thinking approach, the company is poised to continue setting new standards in precision machining and fabrication. As the industry continues to evolve, CNC Precision Manufacturing Company is committed to staying at the forefront of technological advancements and delivering superior products that meet the demands of the modern manufacturing landscape.For companies that demand the highest level of precision and quality in their components, CNC Precision Manufacturing Company stands ready to deliver. With its cutting-edge technology, commitment to innovation, and dedication to customer satisfaction, the company is poised to lead the industry for years to come.

Advanced 5-Axis Lathe Innovations in Machining Technology

The 5 Axis Lathe has been making waves in the manufacturing industry, and for good reason. This cutting-edge technology offers precision and efficiency, revolutionizing the way that parts and components are fabricated. With its advanced capabilities, the 5 Axis Lathe has quickly become a must-have for companies striving to stay ahead of the competition.One company that is leading the way in the adoption of this technology is {Company}. With a strong commitment to innovation and quality, {Company} has recognized the potential of the 5 Axis Lathe and has fully embraced its capabilities. This forward-thinking approach has allowed {Company} to deliver superior products to their customers while maintaining a competitive edge in the market.The 5 Axis Lathe is a sophisticated piece of equipment that offers unmatched versatility and precision. Unlike traditional lathes that operate on three axes, the 5 Axis Lathe can move in five different directions, allowing for more complex and intricate machining processes. This opens up a world of possibilities for creating parts and components with incredibly tight tolerances and intricate geometries.In addition to its enhanced capabilities, the 5 Axis Lathe also offers significant time and cost savings. Thanks to its ability to perform multiple operations in a single setup, it reduces the need for manual intervention and minimizes the risk of human error. This not only speeds up the production process but also improves the overall quality of the finished product.{Company} has fully leveraged these benefits to improve their manufacturing processes and deliver exceptional results to their customers. By investing in the latest technologies, {Company} has positioned itself as a leader in the industry, setting new standards for precision and efficiency. The 5 Axis Lathe has played a key role in this success, allowing {Company} to take on more complex projects and deliver superior products in a shorter timeframe.Furthermore, the 5 Axis Lathe has enabled {Company} to expand their capabilities and take on projects that were previously deemed too challenging. Its ability to machine complex shapes and contours with ease has opened up new opportunities for {Company} to diversify their product offerings and serve a wider range of industries and applications. This has not only strengthened {Company}'s position in the market but has also allowed them to explore new avenues for growth and expansion.One of the key advantages of the 5 Axis Lathe is its ability to reduce setup times and increase production efficiency. With its advanced technology and automated features, {Company} has been able to streamline their workflows and maximize the utilization of their equipment. This has not only improved their overall productivity but has also allowed them to take on more orders and meet the growing demands of their customers.Another noteworthy aspect of the 5 Axis Lathe is its ability to achieve precise and consistent results, even when working with the most challenging materials. {Company} has capitalized on this capability to produce high-quality components that meet the strictest industry standards. This has further solidified {Company}'s reputation as a trusted manufacturer, known for delivering top-notch products that exceed customer expectations.Looking ahead, {Company} is committed to continuing their investment in advanced manufacturing technologies, including the 5 Axis Lathe. By staying at the forefront of innovation, {Company} aims to remain a leader in the industry and continue providing their customers with exceptional products and services.In conclusion, the 5 Axis Lathe has proven to be a game-changer for companies like {Company}, offering unparalleled precision, efficiency, and versatility. As {Company} continues to leverage this technology to its full potential, they are setting new benchmarks for quality and performance in the manufacturing industry. With their unwavering commitment to innovation, {Company} is well-positioned to thrive in the dynamic and competitive landscape of modern manufacturing.

Leading Manufacturer of Silicon Parts: Advantages and Applications

Silicone Parts Manufacturer Leads the Industry with Innovative Technology and Quality ProductsAs the demand for silicone parts continues to rise in various industries, one company has been at the forefront of innovation and quality manufacturing. With a commitment to excellence and a focus on customer satisfaction, [Silicone Parts Manufacturer] has established itself as a leader in the industry.Based in [Location], [Silicone Parts Manufacturer] has been serving customers around the world for over [number] years. The company specializes in the design and production of high-quality silicone parts for a wide range of applications, including automotive, medical, aerospace, and consumer electronics.One of the key factors that sets [Silicone Parts Manufacturer] apart from its competitors is its dedication to innovation. The company invests heavily in research and development to stay ahead of the curve and to continually improve its products and processes. This commitment to innovation has led to the development of several groundbreaking technologies and manufacturing techniques that have revolutionized the industry.In addition to its innovative approach, [Silicone Parts Manufacturer] also prioritizes quality in every aspect of its operations. The company uses only the highest-grade materials and state-of-the-art equipment to ensure that its products meet the highest standards of excellence. From design and prototyping to production and inspection, every step of the manufacturing process is meticulously monitored to guarantee the utmost quality.Furthermore, [Silicone Parts Manufacturer] holds several certifications and accreditations, demonstrating its dedication to maintaining the highest levels of quality and safety. The company is ISO [Number] and [Other Certification] certified, which reflects its adherence to stringent quality management systems and industry best practices.One of the company's most notable achievements is its development of a proprietary silicone molding process, which allows for the production of complex and intricate parts with unparalleled precision and detail. This innovative technology has enabled [Silicone Parts Manufacturer] to offer customized solutions to meet the unique needs of its customers, setting it apart as a trusted partner for companies across diverse industries.In addition to its commitment to innovation and quality, [Silicone Parts Manufacturer] also places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific requirements and to provide tailored solutions that meet and exceed their expectations. With a dedicated team of skilled professionals, [Silicone Parts Manufacturer] is able to offer comprehensive support and guidance throughout the entire product development and manufacturing process.As a result of its relentless pursuit of excellence, [Silicone Parts Manufacturer] has earned a reputation as a trusted and reliable partner in the industry. The company has established long-term relationships with many industry-leading companies, who rely on its expertise and capabilities to deliver superior silicone parts that are critical to their products and operations.Looking to the future, [Silicone Parts Manufacturer] remains committed to pushing the boundaries of innovation and quality in the silicone parts industry. The company continues to invest in research and development, with a focus on developing new technologies and materials that will further enhance its product offerings and manufacturing capabilities. Additionally, [Silicone Parts Manufacturer] is exploring opportunities to expand its presence in emerging markets and to further strengthen its position as a global leader in the industry.For companies seeking a trusted partner for high-quality silicone parts, [Silicone Parts Manufacturer] stands out as a proven industry leader that is dedicated to delivering excellence in every aspect of its operations. With its innovative technologies, uncompromising commitment to quality, and customer-centric approach, [Silicone Parts Manufacturer] is poised to continue setting the standard for excellence in the industry for years to come.

How Precision CNC Machining is Changing the Manufacturing Industry

CNC Precision, a leading precision machining company, has recently announced its addition of state-of-the-art equipment to enhance its capabilities and meet the growing demands of the market. The company, known for its expertise in producing high-quality machined parts for a wide range of industries, has made significant investments in expanding its facilities and acquiring advanced CNC machinery to ensure that it remains at the forefront of precision manufacturing.With a history of delivering excellence in precision engineering, CNC Precision has built a strong reputation for providing custom machined solutions to its clients. The company's commitment to quality, innovation, and customer satisfaction has made it a trusted partner for businesses across various sectors, including aerospace, automotive, medical, and electronics. By continuously investing in the latest technologies and tools, CNC Precision has positioned itself as a leader in the industry, capable of handling complex and challenging projects with precision and efficiency.The recent addition of cutting-edge CNC equipment is a testament to CNC Precision's dedication to staying ahead of the curve in the ever-evolving manufacturing landscape. The new machinery, which includes multi-axis CNC mills and lathes, as well as advanced metrology equipment, will allow the company to expand its capabilities and take on more diverse and intricate machining tasks. This expansion will enable CNC Precision to offer a wider range of services and cater to the evolving needs of its customers, while maintaining its high standards of quality and precision."We are excited to announce the addition of our new CNC machinery to our facility," said the spokesperson for CNC Precision. "This investment represents our commitment to staying at the forefront of precision manufacturing and providing our customers with the best possible solutions. With these new capabilities, we are well-equipped to take on more complex projects and deliver superior results for our clients."In addition to enhancing its machining capabilities, CNC Precision has also expanded its facility to accommodate the new equipment and ensure seamless production processes. The company has invested in infrastructure upgrades, including additional workspace and utilities, to create an optimal environment for its expanded operations. By optimizing its facility layout and workflow, CNC Precision aims to maximize efficiency and productivity, ultimately benefiting its customers with shorter lead times and competitive pricing.With the latest advancements in CNC technology and an expanded facility, CNC Precision is poised to take on new challenges and deliver even greater value to its customers. The company's dedication to innovation and continuous improvement underscores its commitment to being a trusted partner for precision machining solutions. As it continues to push the boundaries of what is possible in precision manufacturing, CNC Precision remains focused on providing exceptional quality, reliability, and expertise to its clients.As businesses across various industries seek custom precision machined parts, CNC Precision stands ready to meet their demands with its expanded capabilities and cutting-edge equipment. With a proven track record of delivering excellence in precision engineering, the company is well-positioned to take on new and complex projects with confidence and expertise. By investing in the latest technologies and expanding its operations, CNC Precision remains a reliable and valuable partner for businesses seeking the highest quality in precision manufacturing.

High-Quality Turned Components for Various Industries

Turned Components has been a leading supplier of precision turned parts for over 20 years. The company has built a strong reputation for delivering high-quality, custom-engineered components to a wide range of industries including automotive, aerospace, medical, and electronics.With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, Turned Components has the capability to produce complex turned parts with tight tolerances and intricate features. The company's commitment to investing in the latest technology and continuous improvement has allowed it to stay ahead of the competition and meet the evolving needs of its customers.Recently, Turned Components announced that they have expanded their production capabilities to meet the growing demand for their products. The company has added new CNC machines and advanced inspection equipment to improve their manufacturing processes and ensure consistent quality.In addition to expanding their production capacity, Turned Components has also invested in training their workforce to operate the new equipment and implement best practices in manufacturing. This investment in skills development demonstrates the company's dedication to maintaining a high level of expertise among their team members."We are excited to announce the expansion of our production capabilities," said [company spokesperson]. "This investment represents our commitment to meeting the needs of our customers and providing them with the highest quality turned components. Our goal is to continue to be a trusted partner for our customers and to exceed their expectations in terms of quality, delivery, and service."The expansion of Turned Components' production capabilities comes at a time of significant growth in the industries they serve. With increasing demand for precision turned parts, the company is positioning itself to be a reliable and responsive supplier in the market.One of the key features of Turned Components' manufacturing process is their ability to produce complex and intricate parts with tight tolerances. This capability is essential for the industries the company serves, where precision and reliability are critical to the performance of the final products.In addition, Turned Components prides itself on its ability to work closely with customers to develop custom solutions to meet their unique requirements. The company's team of engineers and technicians collaborates with customers from the initial design phase through to production, ensuring that the final product meets or exceeds their expectations.With the expansion of their production capabilities, Turned Components is well-positioned to continue to be a leading supplier of precision turned parts for years to come. The company's focus on quality, innovation, and customer satisfaction will enable them to thrive in a competitive manufacturing landscape.For more information about Turned Components and their expanded production capabilities, visit their website [website link].About [company]:Turned Components is a leading supplier of precision turned parts for a range of industries. With over 20 years of experience, the company has built a strong reputation for delivering high-quality, custom-engineered components. Turned Components is committed to investing in the latest technology and continuous improvement to meet the evolving needs of its customers.

Benefits of Flexible Plastic Molding for Various Industries

Flexible Plastic Molding, a leading manufacturer in the plastic molding industry, has been making waves in the market with its innovative and high-quality products. The company has been in operation for over 20 years, providing custom plastic injection molding solutions for a wide range of industries including automotive, medical, consumer goods, and more.Founded in 1998, Flexible Plastic Molding has grown to become a trusted supplier for many top-tier companies, thanks to its commitment to excellence and customer satisfaction. The company's state-of-the-art facilities and advanced technology allow them to produce a wide variety of plastic parts with precision and efficiency.With a team of experienced engineers and designers, Flexible Plastic Molding has the capability to take a project from concept to production, ensuring that each product meets the highest standards of quality and performance. The company's expertise in tooling design and manufacturing enables them to provide cost-effective solutions for complex molding challenges.One of the key factors that sets Flexible Plastic Molding apart from its competitors is its commitment to using innovative materials and processes. The company continuously invests in research and development to stay ahead of industry trends and offer cutting-edge solutions to its clients.In addition to its commitment to innovation, Flexible Plastic Molding is also dedicated to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its manufacturing processes, such as using recyclable materials and reducing waste generation.Furthermore, Flexible Plastic Molding is also focused on maintaining a safe and healthy work environment for its employees. The company complies with industry regulations and standards to ensure the well-being of its workforce while striving for continuous improvement in occupational health and safety.One of the recent achievements of Flexible Plastic Molding is its successful development of a new line of biodegradable plastic products. With the increasing demand for environmentally friendly solutions, the company saw an opportunity to leverage its expertise and technology to create sustainable alternatives to traditional plastics.This new line of biodegradable plastic products is made from plant-based materials that break down naturally, offering a greener alternative to conventional plastic. These products maintain the same level of durability and performance as traditional plastics while minimizing the environmental impact.The introduction of these biodegradable products has received positive feedback from the market, as many companies are looking for ways to reduce their carbon footprint and contribute to a more sustainable future. Flexible Plastic Molding's commitment to environmental stewardship has positioned it as a leader in providing eco-friendly solutions to its clients.In addition to its focus on sustainability, Flexible Plastic Molding continues to invest in research and development to push the boundaries of plastic molding technology. The company has recently expanded its capabilities to include 3D printing and additive manufacturing, allowing them to offer a wider range of services to their clients.Flexible Plastic Molding's dedication to innovation and excellence has earned the company a reputation as a trusted partner in the plastic molding industry. Its ability to deliver high-quality, custom solutions to a diverse range of industries has solidified its position as a leading manufacturer in the market.As Flexible Plastic Molding looks to the future, it remains committed to staying at the forefront of industry advancements and meeting the evolving needs of its clients. With its focus on sustainability, innovation, and quality, the company is well positioned to continue leading the way in the plastic molding industry for years to come.

High-Quality Plastic Molding Services for Precision Engineering Needs

Precision Plastic Molding provides high-quality plastic injection molding solutions for a wide range of industries. With advanced technology and a team of experienced professionals, the company is able to produce precision parts that meet the specific needs of their clients. Their dedication to quality and customer satisfaction has helped them to become a leader in the plastic molding industry.The company specializes in custom plastic injection molding, offering services such as design assistance, prototyping, and production. They work closely with their clients to understand their requirements and develop a customized solution that meets their needs. Whether it's a small batch of parts or a large production run, Precision Plastic Molding has the capabilities to deliver high-quality results.One of the key advantages of working with Precision Plastic Molding is their ability to handle complex projects. They have the expertise and technology to produce intricate parts with tight tolerances, ensuring that the final products meet the exact specifications of their clients. This level of precision and attention to detail has earned them a reputation for excellence in the industry.In addition to their technical capabilities, Precision Plastic Molding also places a strong emphasis on quality control and assurance. They have rigorous processes in place to ensure that every part they produce meets the highest standards of quality. This commitment to excellence has helped them to build long-term relationships with their clients, who trust them to deliver reliable and consistent results.Precision Plastic Molding serves a diverse range of industries, including automotive, medical, consumer electronics, and more. They have the flexibility to work with a variety of materials, including thermoplastics, thermosets, and elastomers, allowing them to meet the needs of clients with different material requirements. This versatility has made them a valuable partner for companies across various sectors.In addition to their technical expertise, Precision Plastic Molding is known for their collaborative approach to project management. They work closely with their clients throughout the entire process, from initial design concept to final production, to ensure that the end result meets their expectations. This level of engagement and communication has helped them to build strong and lasting partnerships with their clients.The company's commitment to innovation is reflected in their investment in advanced technology and equipment. They continue to explore new solutions and techniques to improve their processes and expand their capabilities. This forward-thinking approach has helped them to stay ahead of the curve and remain competitive in the rapidly evolving plastic molding industry.Furthermore, Precision Plastic Molding is dedicated to sustainability and environmental responsibility. They prioritize the use of eco-friendly materials and processes, minimizing waste and reducing their environmental impact. This commitment to sustainability has become increasingly important to their clients, who seek partners that share their values and priorities.Overall, Precision Plastic Molding is a trusted and reliable partner for companies in need of high-quality plastic injection molding solutions. With their technical expertise, commitment to quality, and focus on collaboration and sustainability, they have established themselves as a leader in the industry. Their continued investment in innovation and dedication to customer satisfaction positions them for continued success in the years to come.

High-Quality Injection Mold Factory: Expert Engineering and Manufacturing Services

[Injection Mold Factory] Celebrates 20 Years of Excellence in ManufacturingFor the past two decades, [Injection Mold Factory] has been at the forefront of the manufacturing industry, producing high-quality injection molds for a wide range of industries. As the company celebrates its 20th anniversary, it is a time to reflect on the accomplishments of the past and look forward to the future of manufacturing.Established in [year], [Injection Mold Factory] has consistently strived for excellence in all aspects of its operations. From design and engineering to production and delivery, the company has maintained a commitment to quality and customer satisfaction. This dedication has earned [Injection Mold Factory] a reputation as a leader in the industry and a trusted partner for businesses seeking top-notch injection molds.One of the key factors contributing to the success of [Injection Mold Factory] is its state-of-the-art facility, which is equipped with the latest technology and machinery. This allows the company to produce molds that meet the highest standards of precision and performance. Additionally, the company’s team of skilled technicians and engineers ensures that each mold is tailored to the specific needs of the customer, resulting in customized solutions that deliver exceptional results.In addition to its focus on quality and precision, [Injection Mold Factory] is also committed to sustainability and environmental responsibility. The company has implemented various initiatives to minimize its environmental impact, including the use of eco-friendly materials and processes. By prioritizing sustainability, [Injection Mold Factory] not only reduces its carbon footprint but also sets a standard for responsible manufacturing in the industry.As part of its 20th-anniversary celebrations, [Injection Mold Factory] is looking to the future with a renewed commitment to innovation and growth. The company has plans to expand its operations and invest in additional technology and equipment to further improve its capabilities. By staying at the forefront of technological advancements, [Injection Mold Factory] aims to continue meeting the evolving needs of its customers and maintain its position as a leader in the industry.Moreover, [Injection Mold Factory] is dedicated to fostering talent and nurturing the next generation of manufacturing professionals. The company provides training and development opportunities for its employees, ensuring that they have the skills and knowledge to excel in their roles. By investing in its workforce, [Injection Mold Factory] not only strengthens its own capabilities but also contributes to the growth and success of the manufacturing industry as a whole.Looking ahead, [Injection Mold Factory] is optimistic about the future and the opportunities that lie ahead. The company remains committed to delivering exceptional products and service to its customers while continuing to uphold its values of quality, precision, and sustainability. With a strong foundation built over the past two decades, [Injection Mold Factory] is well-positioned to embrace the challenges and opportunities of the future, further solidifying its standing as a leader in the manufacturing industry.

Sheet Metal Punch Processing Fabrication for Aluminum Material

Aluminum Sheet Metal Punch Processing Fabrication Bringing High-Quality Products to the MarketIn the world of manufacturing and fabrication, precision and efficiency are crucial. Companies are constantly seeking ways to produce high-quality products in a timely manner, and the latest innovation in aluminum sheet metal punch processing fabrication has been making waves in the industry. With cutting-edge technology and a commitment to excellence, [Company Name] has been at the forefront of this development, delivering top-notch sheet metal processing services to meet the needs of various industries.Established in [Year], [Company Name] has earned a stellar reputation for its expertise in aluminum sheet metal fabrication. With a skilled team of engineers and technicians, the company has been providing comprehensive fabrication solutions to meet the diverse needs of its clients. From custom designs to large-scale production, [Company Name] has the capabilities to deliver precision-made products that exceed industry standards.One of the key innovations that [Company Name] has been acclaimed for is its aluminum sheet metal punch processing fabrication. This advanced manufacturing technique allows for the precise punching of holes, notches, and other shapes into aluminum sheet metal, providing a cost-effective and efficient solution for various applications. With state-of-the-art equipment and a commitment to quality control, [Company Name] ensures that each product meets the highest standards of precision and accuracy.The process of aluminum sheet metal punch processing fabrication involves the use of specialized punch press machines that exert high force to pierce through the aluminum sheet metal. This method allows for the creation of intricate patterns and designs, as well as the incorporation of functional features such as mounting holes, slots, and tabs. As a result, manufacturers across industries such as automotive, aerospace, electronics, and consumer goods have been benefiting from the versatility and efficiency of this fabrication technique.In addition to its advanced manufacturing capabilities, [Company Name] places a strong emphasis on environmental sustainability and responsible production practices. The company is committed to minimizing its environmental impact by adhering to strict waste management protocols and investing in energy-efficient technologies. By implementing sustainable measures in its operations, [Company Name] not only demonstrates its dedication to corporate social responsibility but also contributes to the overall sustainability of the manufacturing industry.Another noteworthy aspect of [Company Name]'s aluminum sheet metal punch processing fabrication is its ability to cater to custom projects and specialized requirements. The company's team of engineers and designers work closely with clients to understand their specific needs and deliver tailored solutions that align with their goals. Whether it's a unique design requirement or a complex fabrication challenge, [Company Name] is well-equipped to address the demands of its diverse clientele.Furthermore, [Company Name] places a strong emphasis on quality assurance throughout the entire fabrication process. Every step of the manufacturing process is subject to rigorous quality control measures to ensure that the final products meet the highest standards of excellence. From material selection to final inspection, [Company Name] maintains strict quality standards to uphold its reputation for delivering superior products to its customers.As [Company Name] continues to lead the way in aluminum sheet metal punch processing fabrication, it remains dedicated to staying at the forefront of innovation in the manufacturing industry. By investing in cutting-edge technologies, refining its processes, and fostering a culture of continuous improvement, the company is well-positioned to meet the evolving demands of its clients and the market.In conclusion, [Company Name] has established itself as a trusted partner for companies seeking high-quality aluminum sheet metal punch processing fabrication. With its commitment to precision, efficiency, and sustainability, the company has earned accolades for its contributions to the manufacturing industry. As the demand for top-notch fabrication services continues to grow, [Company Name] remains steadfast in its mission to deliver exceptional products that meet and exceed the expectations of its customers.With its proven track record and dedication to excellence, [Company Name] is poised to continue its success in the field of aluminum sheet metal punch processing fabrication, serving as a valuable resource for companies seeking reliable and innovative fabrication solutions.