Ultimate Guide to LDPE Injection Molding: Everything You Need to Know

By:Admin

Founded in [year], {} has established itself as a pioneer in the LDPE injection molding industry, delivering innovative solutions and top-quality products to meet the diverse needs of its clients. The company's state-of-the-art manufacturing facilities and cutting-edge technology have enabled them to produce a wide range of LDPE injection-molded products, including containers, packaging materials, and industrial components.

{}'s commitment to quality and excellence has earned them a strong reputation in the LDPE injection molding market. With a team of highly skilled engineers and technicians, the company is dedicated to delivering superior products that meet the highest industry standards. Their focus on continuous improvement and innovation has allowed them to stay ahead of the competition and provide customers with the best-in-class LDPE injection-molded products.

One of the key factors driving the growth of the LDPE injection molding market is the increasing demand for sustainable and environmentally friendly packaging solutions. With the global push towards reducing plastic waste and adopting eco-friendly materials, LDPE injection-molded products have gained traction as a preferred choice for many companies. {} has been at the forefront of this trend, producing LDPE injection-molded products that are not only high in quality but also environmentally sustainable.

In addition to their commitment to sustainability, {} has also been proactive in adopting advanced manufacturing practices to improve efficiency and reduce production costs. By leveraging the latest technologies and streamlining their production processes, the company has been able to offer competitive pricing without compromising on product quality. This has further strengthened their position as a leading provider of LDPE injection-molded products in the market.

Furthermore, {} has also expanded its reach to cater to a wide range of industries, including pharmaceuticals, food and beverage, automotive, and consumer goods. Their diverse product portfolio and customized solutions have allowed them to serve a broad customer base, catering to unique requirements and specifications of different industries. This flexibility and versatility have positioned {} as a preferred partner for companies seeking reliable and high-quality LDPE injection-molded products.

Looking ahead, {} is poised for continued growth and success in the LDPE injection molding industry. With a strong focus on innovation, sustainability, and customer satisfaction, the company is well-positioned to capitalize on the growing demand for LDPE injection-molded products. As the industry continues to evolve, {} remains committed to pushing the boundaries of excellence and delivering cutting-edge solutions that meet the dynamic needs of their customers.

In conclusion, the LDPE injection molding industry is experiencing rapid growth, driven by increasing demand for high-quality plastic products and sustainable packaging solutions. {} has emerged as a key player in this thriving market, offering top-notch LDPE injection-molded products and setting the benchmark for quality and innovation. With a relentless focus on customer satisfaction and a dedication to excellence, {} is well-equipped to lead the way in the LDPE injection molding industry for years to come.

Company News & Blog

Benefits of Laser Prototyping for Rapid Product Development

Laser Prototyping Technology Revolutionizes Manufacturing IndustryThe manufacturing industry is constantly evolving, with new technologies and advancements changing the way products are developed and produced. One of the most recent and groundbreaking innovations in the industry is the use of laser prototyping technology. This cutting-edge technology is revolutionizing the manufacturing process by allowing companies to create high-quality prototypes and production parts with unmatched speed and precision.Laser prototyping, also known as rapid prototyping, is a process that uses a high-powered laser to selectively sinter powdered materials, such as metals, plastics, or ceramics, layer by layer to create three-dimensional objects. This technology is incredibly versatile and can be used to produce complex geometries and intricate designs that would be difficult or impossible to achieve using traditional manufacturing methods. Furthermore, laser prototyping allows for rapid iteration and customization, making it an ideal solution for companies in need of quick turnaround times and flexible production capabilities.One company at the forefront of laser prototyping technology is {}. Founded in 1999, {} has been a pioneer in the development and implementation of advanced laser systems for a wide range of industrial applications. With a strong focus on innovation and customer satisfaction, {} has continuously pushed the boundaries of what is possible with laser technology, creating solutions that have redefined the manufacturing industry.{}'s laser prototyping systems utilize state-of-the-art laser sources and advanced powder bed fusion techniques to deliver exceptional part quality and dimensional accuracy. The company's integrated software and hardware solutions enable precise control over the laser sintering process, allowing for the creation of highly detailed and functional prototypes and production parts. In addition, {}'s laser systems are designed for scalability, making them suitable for small-scale rapid prototyping as well as large-scale industrial production.The benefits of laser prototyping technology extend beyond its technical capabilities. By streamlining the product development cycle and reducing the need for expensive tooling and machining, laser prototyping can significantly lower production costs and time to market. This has a direct impact on a company's bottom line and overall competitiveness in the market. Furthermore, the ability to quickly iterate and test designs allows for more efficient development processes and ultimately leads to better end products.In recent years, {} has seen a surge in demand for its laser prototyping systems from a diverse range of industries, including aerospace, automotive, medical, and consumer goods. This reflects the growing recognition of the value that laser prototyping brings to the table in terms of innovation, efficiency, and quality. As the manufacturing industry continues to evolve, it is clear that laser prototyping will play a crucial role in shaping the future of product development and production.With a strong track record of delivering cutting-edge laser solutions and a commitment to empowering its customers with the latest technology, {} is well-positioned to lead the charge in the widespread adoption of laser prototyping. The company's dedication to pushing the boundaries of what is possible with laser technology, coupled with its focus on customer satisfaction, has positioned it as a trusted partner for companies looking to harness the power of laser prototyping to gain a competitive edge in their respective industries.In conclusion, laser prototyping technology is a game-changer for the manufacturing industry, offering unparalleled speed, precision, and flexibility in the production of prototypes and production parts. With {} leading the charge in the development and implementation of advanced laser prototyping systems, the future of manufacturing looks brighter than ever. As companies continue to embrace this revolutionary technology, the possibilities for innovation and success are endless.

High Precision CNC Mill for Superior Machining

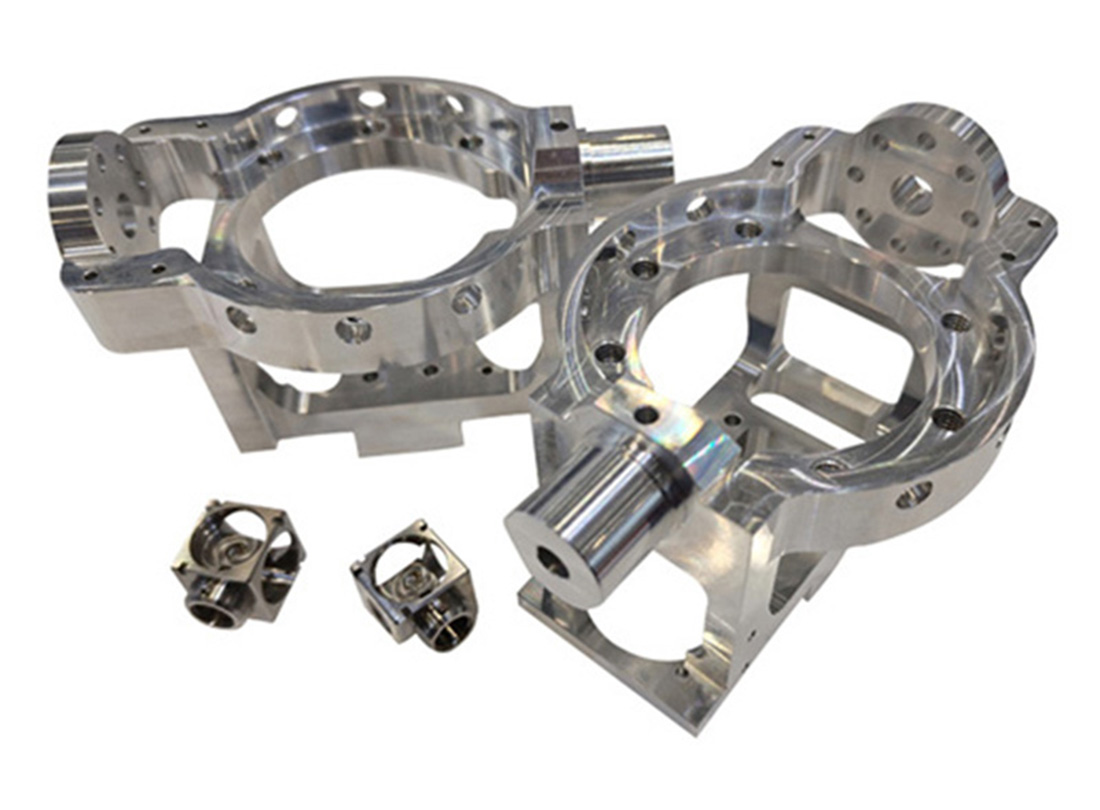

High Precision CNC Mill Revolutionizes Manufacturing IndustryWith the continuous advancement in technology, the manufacturing industry is witnessing a significant transformation. The introduction of high precision CNC mills has taken manufacturing to a new level, enabling companies to produce complex and intricate components with unparalleled precision and accuracy. One such company at the forefront of this technological revolution is {}, a leading manufacturer of advanced CNC machines. With a strong focus on innovation and quality, the company has been driving the industry forward with its cutting-edge technology and state-of-the-art solutions.The high precision CNC mill developed by {} has set a new benchmark in the industry, offering unmatched levels of precision and efficiency. This advanced machine is equipped with the latest control systems and cutting-edge software, allowing for seamless integration of complex designs and precise machining operations. The result is a finished product that meets the highest standards of quality and accuracy.One of the key features of the high precision CNC mill is its ability to produce components with tight tolerances and intricate geometries. This has opened up new possibilities for companies across a wide range of industries, including aerospace, automotive, medical, and electronics. The ability to produce complex parts with high precision has enabled manufacturers to push the boundaries of what is possible, leading to innovation and advancements in various sectors.In addition to its precision capabilities, the CNC mill also offers high levels of productivity and efficiency. The advanced automation features and powerful cutting tools allow for rapid production of components, reducing lead times and increasing overall throughput. This has led to significant improvements in manufacturing processes, resulting in higher productivity and cost savings for companies utilizing this technology.Another important aspect of the high precision CNC mill is its versatility. It is capable of machining a wide range of materials, including metals, plastics, and composites, making it suitable for a variety of applications. This flexibility has made the CNC mill a valuable asset for companies looking to expand their capabilities and take on a diverse range of projects.Furthermore, the CNC mill has been designed with user-friendly interfaces and intuitive controls, making it easy for operators to set up, program, and monitor machining operations. This has reduced the learning curve for operators, allowing them to quickly adapt to the new technology and maximize its potential.Moreover, the high precision CNC mill is equipped with advanced safety features to ensure a secure working environment for operators. With built-in sensors and safety protocols, the machine is able to detect and respond to potential hazards, minimizing the risk of accidents and injuries in the workplace.{} has also been proactive in providing comprehensive training and support for its customers, ensuring that they have the knowledge and resources to fully utilize the capabilities of the high precision CNC mill. This commitment to customer satisfaction has helped the company build a strong reputation in the industry, with a track record of delivering reliable and high-performance machines.Overall, the introduction of high precision CNC mills has been a game-changer for the manufacturing industry, offering a level of precision, efficiency, and versatility that was previously unattainable. As technology continues to evolve, the potential for further advancements in CNC machining is limitless, and companies like {} are leading the way in shaping the future of manufacturing.

High-Quality CNC Turned Components for Precision Engineering

[Company Name], a leading manufacturer of precision machined components, announced the launch of a new line of CNC turned components. The company, known for its high-quality products and innovative solutions, has expanded its offerings to meet the growing demand for precision components in various industries.The new line of CNC turned components is manufactured using state-of-the-art machinery and advanced technologies. This allows for the production of complex and intricate components with tight tolerances and high accuracy. The components are designed to meet the specific requirements of customers in industries such as automotive, aerospace, medical, and electronics.With a focus on precision and quality, [Company Name] has invested in the latest CNC turning technology to ensure that the components meet the highest standards. The company's team of skilled engineers and technicians work closely with customers to understand their needs and provide custom solutions that meet their exact specifications.“We are thrilled to announce the launch of our new line of CNC turned components,” said [Spokesperson Name], CEO of [Company Name]. “With the increasing demand for precision components in various industries, we saw an opportunity to expand our product offerings and provide our customers with high-quality solutions that meet their specific needs.”[Company Name] has a strong track record of delivering precision components that meet and exceed the expectations of its customers. The company's commitment to quality and continuous improvement has earned it a reputation as a trusted partner for precision machining needs.In addition to the new line of CNC turned components, [Company Name] offers a wide range of services including CNC milling, turning, grinding, and assembly. The company's capabilities allow it to handle projects of all sizes and complexities, from prototyping to high-volume production.“We understand the importance of precision and accuracy in the manufacturing process, which is why we have invested in the latest technologies and equipment to ensure that we deliver components that meet the highest standards,” said [Spokesperson Name]. “Our team is dedicated to providing our customers with the best possible solutions to meet their needs, and we are excited to expand our offerings with the new line of CNC turned components.”With the launch of the new line of CNC turned components, [Company Name] aims to strengthen its position as a leading provider of precision machined components. The company's commitment to quality, innovation, and customer satisfaction sets it apart in the industry and positions it for continued success.As the demand for precision components continues to grow across various industries, [Company Name] is well-positioned to meet the needs of its customers with its new line of CNC turned components. The company's dedication to excellence and customer satisfaction ensures that it will remain a trusted partner for precision machining needs.[Company Name] invites customers to learn more about its new line of CNC turned components and explore the possibilities for custom solutions that meet their specific requirements. With its focus on quality, precision, and innovation, the company is poised to lead the way in providing high-quality machining solutions for various industries.

Top Tips for Successful Injection Molding

Injection molding is a highly versatile method used in the manufacturing industry to produce a wide range of products and components. This process involves melting a thermoplastic material and injecting it into a mold cavity, where it is then cooled and solidified to form the desired shape. One company at the forefront of injection molding technology is {}. With their state-of-the-art facilities and advanced machinery, they have been able to offer innovative solutions to their clients across various industries. {} has built a strong reputation for delivering high-quality products and components using injection molding. They have a team of experienced engineers and technicians who work closely with clients to understand their specific requirements and provide customized solutions. From design and prototyping to production and assembly, {} offers a comprehensive range of services to meet the needs of their clients. The company is committed to staying ahead of the curve when it comes to injection molding technology. They continuously invest in the latest machinery and equipment to ensure that they are able to deliver precise and efficient manufacturing solutions. This commitment to innovation has enabled {} to stay competitive in the market and maintain their position as a leading provider of injection molded products.In addition to their technical capabilities, {} also places a strong emphasis on quality control and process optimization. They have implemented strict quality management systems to ensure that each product that comes out of their facility meets the highest standards. This dedication to quality has earned them the trust and confidence of their clients, who rely on {} to deliver reliable and durable products.{} serves a diverse range of industries, including automotive, consumer electronics, medical, and more. Their ability to cater to the unique needs of each industry and provide tailored solutions sets them apart from their competitors. Whether it's manufacturing precision components for the automotive sector or producing medical devices with strict regulatory requirements, {} has the expertise and resources to deliver on their clients' expectations.As a responsible corporate citizen, {} is also committed to sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes and strive to minimize their environmental footprint. By using recyclable materials and optimizing their energy consumption, {} is dedicated to reducing their impact on the environment while still delivering exceptional products.Looking towards the future, {} is poised to continue leading the way in injection molding technology. They are continuously exploring new materials, processes, and techniques to improve their capabilities and expand their offerings. By staying at the forefront of technological advancements, {} is well-positioned to meet the evolving needs of their clients and remain a trusted partner in the manufacturing industry.In conclusion, injection molding is a crucial process in the manufacturing industry, and {} has established itself as a key player in this field. With their commitment to innovation, quality, and sustainability, they have earned a strong reputation and a loyal client base. As they continue to invest in their capabilities and adapt to the changing industry landscape, {} is well-prepared to maintain their leadership position and drive the future of injection molding technology.

Durable Rubber Hoses for Your Vehicle

Rubber Hoses for Cars: Ensuring Quality and PerformanceIn the automotive industry, the importance of high-quality rubber hoses for cars cannot be overstated. These hoses play a critical role in ensuring the proper functioning of various systems within a vehicle, including the cooling system, fuel system, and hydraulic systems. As such, it is crucial for car manufacturers and consumers alike to understand the significance of using reliable and durable rubber hoses in their vehicles.One company that has been leading the way in the production of top-notch rubber hoses for cars is {}. With a strong commitment to excellence and innovation, they have established themselves as a trusted name in the industry, providing high-quality hoses that meet and exceed the stringent requirements of modern automobiles.The company's dedication to quality is evident in its state-of-the-art manufacturing facilities, where advanced production processes and rigorous quality control measures are employed to ensure that every rubber hose that comes off the production line meets the highest standards. This commitment to excellence has earned them the trust and confidence of leading car manufacturers and aftermarket suppliers around the world.One of the key factors that set {} apart from its competitors is its extensive research and development efforts. The company invests significantly in R&D to stay ahead of the curve and continuously improve the performance and durability of its rubber hoses. This relentless pursuit of innovation has led to the development of cutting-edge materials and manufacturing techniques that enhance the reliability and longevity of their products.Moreover, {}'s rubber hoses for cars are designed to withstand the harshest operating conditions. Whether it's extreme temperatures, high pressures, or corrosive fluids, these hoses are engineered to deliver uncompromising performance and durability. This level of resilience is crucial in ensuring the safe and efficient operation of vital automotive systems.Beyond their technical excellence, {} is also committed to environmental sustainability. The company employs eco-friendly manufacturing practices and utilizes recyclable materials wherever possible, reducing its carbon footprint and contributing to a greener future. This dedication to sustainability aligns with the growing global emphasis on environmental responsibility and sets {} apart as a socially conscious industry leader.In addition to their commitment to quality, innovation, and sustainability, {} also places a strong emphasis on customer satisfaction. The company's customer support team is dedicated to providing prompt and professional assistance to clients, whether they are car manufacturers, distributors, or end consumers. This focus on customer service has helped {} build lasting relationships with its partners and customers, fostering a reputation for reliability and trustworthiness.Looking ahead, {} remains poised for continued success and growth in the global automotive industry. With a strong focus on technological advancement and a steadfast commitment to quality and customer satisfaction, the company is well-positioned to meet the evolving needs of the market and maintain its position as a premier supplier of rubber hoses for cars.In conclusion, the importance of high-quality rubber hoses for cars cannot be overstated, and {} stands as a shining example of a company that is dedicated to delivering excellence in this critical aspect of automotive engineering. Through its unwavering commitment to quality, innovation, and customer satisfaction, {} continues to raise the bar for the industry, ensuring that vehicles around the world are fitted with rubber hoses that deliver exceptional performance and reliability.

Advanced 5 Axis Cnc Milling Technology for Precision Machining

The demand for high-precision manufacturing in various industries has been growing rapidly in recent years. In response to this increasing demand, the use of 5-axis CNC mills has become more prevalent due to their ability to produce complex and intricate parts with unparalleled accuracy. One company at the forefront of this technological advancement is {Company Name}.{Company Name} is a leading manufacturer of 5-axis CNC mills, specializing in providing high-quality machining solutions for a wide range of industries including aerospace, automotive, medical, and more. With a strong focus on innovation and continuous improvement, {Company Name} has established itself as a trusted partner for businesses seeking advanced machining capabilities.The 5-axis CNC mill offered by {Company Name} is equipped with cutting-edge technology that allows for simultaneous machining from multiple angles, resulting in faster production times and higher precision. This advanced equipment is capable of handling a wide variety of materials including metals, plastics, composites, and more, making it a versatile solution for the diverse needs of modern manufacturing.One of the key features of {Company Name}'s 5-axis CNC mill is its ability to perform complex machining operations with ease. This includes the machining of intricate shapes, contours, and surfaces that would be difficult or impossible to achieve with traditional 3-axis or 4-axis milling machines. The 5-axis capability also allows for the reduction of setup times and the elimination of multiple setups, leading to increased efficiency and cost savings for customers.In addition to its cutting-edge technology, {Company Name} also prides itself on providing exceptional customer support and service. The team at {Company Name} is comprised of highly skilled and experienced professionals who are dedicated to helping customers maximize the potential of their 5-axis CNC mill. Whether it's providing training, technical support, or custom machining solutions, {Company Name} is committed to ensuring that its customers are able to achieve their manufacturing goals with the highest level of satisfaction.Furthermore, {Company Name} is committed to sustainability and environmental responsibility. The 5-axis CNC mill offered by the company is designed to minimize waste and optimize material usage, contributing to a greener and more efficient manufacturing process. This is in line with {Company Name}'s commitment to reducing its environmental impact and promoting sustainable manufacturing practices.As the demand for high-precision manufacturing continues to increase, the need for advanced machining solutions such as 5-axis CNC mills will only grow. With its innovative technology, exceptional customer support, and commitment to sustainability, {Company Name} is well-positioned to meet this demand and remain a leader in the industry.In conclusion, {Company Name} is revolutionizing the manufacturing industry with its state-of-the-art 5-axis CNC mill. By combining cutting-edge technology with exceptional customer support and a commitment to sustainability, {Company Name} is empowering businesses to achieve new levels of precision and efficiency in their machining operations. As the industry continues to evolve, {Company Name} will undoubtedly remain at the forefront, providing innovative solutions to meet the ever-changing needs of modern manufacturing.

Benefits of Rapid Injection Molding for Quick Manufacturing

Rapid Injection Molding Offers Quick and Efficient Production Solutions for Various IndustriesIn today's rapidly evolving market, companies are constantly looking for ways to streamline their production processes and bring their products to market faster. This need for speed and efficiency has given rise to the growing demand for rapid injection molding services. One company that has been leading the way in this space is {}. With their state-of-the-art technology and years of experience, they have been offering quick and efficient production solutions for various industries, making them a trusted partner for companies looking to accelerate their production timelines.The process of injection molding involves injecting molten material into a mold cavity to create a part. This method is widely used for the mass production of plastic parts, as it allows for high-quality, consistent parts to be produced at a rapid pace. However, traditional injection molding methods can be time-consuming and expensive, with long lead times and high tooling costs. This is where rapid injection molding comes in.Rapid injection molding is a fast and cost-effective alternative to traditional injection molding. It utilizes advanced technology and streamlined processes to reduce lead times and lower tooling costs, making it an ideal solution for companies looking to bring their products to market quickly and efficiently. By using rapid injection molding, companies can iterate their designs more quickly, reduce time to market, and ultimately gain a competitive edge in their industry.{} has been at the forefront of rapid injection molding, offering a wide range of services to meet the diverse needs of their clients. With a team of experienced engineers and technicians, they are able to provide comprehensive support throughout the entire production process, from design and prototyping to final part production. Their advanced manufacturing facilities are equipped with the latest injection molding machines and tooling technology, allowing them to produce high-quality parts with short lead times.One of the key advantages of partnering with {} for rapid injection molding is their ability to produce complex parts with precision and consistency. Their advanced tooling technology and process optimization allow for tight tolerances and high repeatability, ensuring that each part meets the strictest quality standards. This is particularly important for industries such as automotive, aerospace, and electronics, where complex and precise parts are a necessity.Additionally, {}'s rapid injection molding services are highly cost-effective, offering competitive pricing and low tooling costs. This makes it an attractive option for companies of all sizes, whether they are looking to produce a small batch of parts or scale up to high-volume production. With their quick turnaround times and efficient processes, companies can save time and money while still receiving high-quality parts.As the demand for rapid injection molding continues to grow, {} remains committed to staying at the forefront of the industry. They invest in cutting-edge technologies and continuously improve their processes to offer the best possible solutions for their clients. With a focus on innovation and customer satisfaction, they have built a solid reputation as a trusted partner for companies looking to accelerate their production timelines and bring their products to market faster.In conclusion, rapid injection molding has become a vital tool for companies looking to compete in today's fast-paced market. With its ability to produce high-quality parts quickly and cost-effectively, it offers a valuable advantage for businesses across various industries. Through their expertise and state-of-the-art technology, {} has established itself as a leading provider of rapid injection molding services, empowering companies to bring their innovative products to market with speed and efficiency.

Ultimate Guide to Thermoplastic Injection Molding: Everything You Need to Know

[Company Introduction] is a leading manufacturer of thermoplastic injection molding machines, providing innovative and reliable solutions for a wide range of industries. With a strong focus on research and development, the company has established itself as a pioneer in the field of plastic injection technology. By constantly pushing the boundaries of what is possible, has earned a reputation for excellence and continues to lead the way in the industry. [News Content] Thermoplastic injection molding technology has revolutionized the way products are manufactured across various industries. It has significantly improved the efficiency, precision, and cost-effectiveness of producing a wide range of plastic products. The process involves injecting molten material into a mold cavity, where it solidifies to form the desired shape. This method has become increasingly popular due to its ability to produce high-quality and complex parts with ease. One of the key players in the thermoplastic injection molding industry is {}. The company has been at the forefront of developing cutting-edge injection molding machines that are designed to meet the evolving needs of the market. By combining state-of-the-art technology with a strong focus on innovation, has consistently delivered superior solutions to its customers. Recently, {} announced the launch of its latest series of thermoplastic injection molding machines, which are set to raise the bar in terms of performance and reliability. These machines have been meticulously designed to offer enhanced precision, speed, and energy efficiency, making them an ideal choice for manufacturers looking to streamline their production processes. The new series of injection molding machines from {} features a range of advanced capabilities that set them apart from the competition. One of the standout features is their ability to achieve unparalleled levels of precision, ensuring that each molded product meets the highest standards of quality. This is made possible by the incorporation of cutting-edge servo motor technology, which enables precise control of the injection process. In addition to precision, the new machines also offer impressive speed and efficiency. Thanks to their advanced hydraulic systems and optimized design, they can deliver faster cycle times without compromising on quality. This means that manufacturers can significantly increase their production output while maintaining high levels of product consistency. Furthermore, {}'s new series of injection molding machines are engineered for energy efficiency, helping manufacturers reduce their operational costs and environmental impact. By incorporating energy-saving features such as variable frequency drives and advanced cooling systems, these machines consume less power without sacrificing performance. This makes them a sustainable and cost-effective choice for businesses looking to minimize their carbon footprint. Overall, the latest series of thermoplastic injection molding machines from {} represents a significant leap forward in the industry. With their unmatched precision, speed, and energy efficiency, these machines are poised to set a new standard for plastic injection technology. As the demand for high-quality plastic products continues to grow, manufacturers can rely on {} to provide them with the tools they need to stay competitive in the market.

Create Functional Prototypes for Your Product with These Tips

Functional Prototypes Making Strides in {} IndustryIn the fast-paced world of technology and innovation, the creation of functional prototypes plays a crucial role in the development and design of new products. {} is at the forefront of this industry, offering cutting-edge solutions for companies in need of high-quality prototypes.With a strong focus on the latest technological advancements, {} has established itself as a leader in the field of functional prototypes. The company's dedication to precision and quality has set it apart from its competitors, earning the trust and confidence of clients across various industries.{}'s state-of-the-art facilities are equipped with advanced machinery and software, allowing for the production of complex and highly detailed prototypes. The company's team of skilled engineers and designers work closely with clients to understand their specific needs and requirements, ensuring that each prototype is tailored to perfection.One of the key advantages of {}'s services is the speed at which prototypes can be produced. The company's streamlined process and efficient workflow enable clients to receive their prototypes in a timely manner, allowing them to move forward with their product development and testing.Furthermore, {}'s dedication to quality control ensures that each prototype meets the highest standards of excellence. Rigorous testing and inspection procedures are carried out to guarantee that the final product is free of any defects or imperfections.The impact of {}'s functional prototypes can be seen in a wide range of industries, from automotive and aerospace to consumer electronics and medical devices. By providing clients with accurate and reliable prototypes, {} is helping to drive innovation and progress in various sectors.{}'s commitment to innovation and excellence has earned it a stellar reputation in the industry, with a growing list of satisfied clients who have benefited from its services. The company's ability to deliver on its promises and exceed expectations has solidified its position as a trusted partner for companies in need of functional prototypes.As technology continues to advance at a rapid pace, the demand for functional prototypes is only expected to grow. {} is well-positioned to meet this demand, thanks to its cutting-edge capabilities and unwavering commitment to excellence.In the coming years, {} aims to expand its reach and further cement its status as a leader in the field of functional prototypes. By staying ahead of the curve and embracing new technologies and techniques, the company is poised to continue making significant contributions to the world of innovation and product development.In conclusion, {} is revolutionizing the way companies approach the creation of functional prototypes. With its advanced capabilities, streamlined process, and unwavering commitment to quality, the company is setting new standards in the industry and helping to shape the future of technology and innovation. Clients can trust in {} to deliver top-of-the-line prototypes that meet their specific needs and propel their product development efforts forward.

Benefits of Prototype Plastic Molding for your Business

Prototype Plastic Molding, a leading provider of custom plastic injection molding solutions, has recently expanded their services to better serve the growing demand for high-quality plastic parts in various industries. With over 20 years of experience in the industry, Prototype Plastic Molding has become a trusted partner for companies looking for reliable and cost-effective plastic molding solutions.The company is known for its state-of-the-art facilities, highly skilled team of engineers and technicians, and commitment to delivering top-notch products to their clients. They offer a wide range of services including product design and development, mold making, injection molding, assembly, and packaging. Their expertise in the field has allowed them to work with clients in industries such as automotive, medical, consumer goods, and more.One of the key factors that set Prototype Plastic Molding apart from their competitors is their dedication to using the latest technology and equipment in their manufacturing processes. This allows them to produce parts with high precision, consistency, and efficiency, while also reducing lead times and overall costs for their clients.In response to the increasing demand for sustainable manufacturing practices, Prototype Plastic Molding has also made significant investments in environmentally friendly initiatives. They have implemented processes and materials to reduce waste, minimize energy consumption, and decrease their carbon footprint. This commitment to sustainability not only benefits the environment but also positions them as a forward-thinking and socially responsible partner for their clients.As part of their expansion efforts, Prototype Plastic Molding has recently added new injection molding machines to their production line. These machines are equipped with the latest technology to improve efficiency and capacity, allowing the company to take on larger and more complex projects. Additionally, they have expanded their workforce to accommodate the growing demand for their services, hiring new talent with expertise in various aspects of plastic molding.The company's dedication to continuous improvement and innovation has earned them a solid reputation in the industry. They are committed to staying ahead of the curve and offering cutting-edge solutions to their clients. This dedication has led to long-standing partnerships with many of their clients, who rely on Prototype Plastic Molding for their expertise and reliability.In addition to their expansion efforts, Prototype Plastic Molding also remains focused on providing exceptional customer service. They understand the importance of clear communication, attention to detail, and on-time delivery for their clients. Their team works closely with each client to understand their specific needs and develop customized solutions that meet their requirements.Looking ahead, Prototype Plastic Molding is poised for continued growth and success in the industry. They are committed to staying at the forefront of plastic molding technology, expanding their capabilities, and providing even greater value to their clients. With their dedication to quality, innovation, and customer satisfaction, Prototype Plastic Molding is well-positioned to remain a leader in the custom plastic injection molding industry for years to come.